LastingLaserImpressions

Members-

Content Count

44 -

Joined

-

Last visited

About LastingLaserImpressions

-

Rank

Member

- Birthday 06/05/1953

Contact Methods

-

Website URL

http://www.llimpressions.com

Profile Information

-

Gender

Male

-

Location

Chandler, Arizona

-

Interests

Laser engraving, Leather designs, Shooting sports, Music and Family

LW Info

-

Leatherwork Specialty

Just beginning (again)

-

Interested in learning about

tooling leather

-

How did you find leatherworker.net?

Friend and leatherworker Rick Henry

-

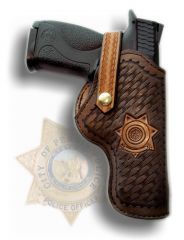

IMG_0212.JPG

LastingLaserImpressions commented on diamondbleather's gallery image in Our Leatherwork Galleries

-

Action shooting holster

LastingLaserImpressions commented on Hedge's gallery image in Our Leatherwork Galleries

-

PerrisFront.jpg

LastingLaserImpressions commented on lilrays's gallery image in Our Leatherwork Galleries

-

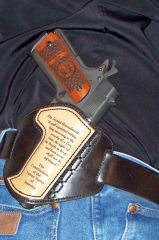

1911 and 2nd amendment holster 6.jpg

LastingLaserImpressions commented on LastingLaserImpressions's gallery image in Our Leatherwork Galleries

-

Keep up the good work and someday a customer will be on here stating that he is building gun leather but carries his in a JRC holster. Continued success.

-

IWB_P1_Back_600.jpg

LastingLaserImpressions commented on JRCHolsters's gallery image in Our Leatherwork Galleries

-

Leather Chess Table

LastingLaserImpressions commented on CitizenKate's gallery image in Our Leatherwork Galleries

-

Ornamental tabletop Backgammon board, ver. 2

LastingLaserImpressions commented on CitizenKate's gallery image in Our Leatherwork Galleries

-

laser at work.jpg

LastingLaserImpressions commented on LastingLaserImpressions's gallery image in Our Leatherwork Galleries

Mountain Man if you are talking about the laser itself, $7k - 30k depending on wattage and bed size. Add software, scanner and computer and accessories... and like any venture the total starts to run up. A replacement laser unit can cost up to $3k. It is just like tooling leather in that you can start with basic tools but then you find the difference in tool quality and knives, the next thing you know you have hundreds and not more wrapped up in your hobby/business. Let's just say it ain't cheap. That is why I use it on a variety of materials not just leather. Thanks for your comment. -

1911 and 2nd amendment holster 3.jpg

LastingLaserImpressions commented on LastingLaserImpressions's gallery image in Our Leatherwork Galleries

-

1911 and 2nd amendment holster 11.jpg

LastingLaserImpressions commented on LastingLaserImpressions's gallery image in Our Leatherwork Galleries

-

laser at work.jpg

LastingLaserImpressions commented on LastingLaserImpressions's gallery image in Our Leatherwork Galleries

-

laser at work.jpg

LastingLaserImpressions commented on LastingLaserImpressions's gallery image in Our Leatherwork Galleries

-

1911 and 2nd amendment holster 3.jpg

LastingLaserImpressions commented on LastingLaserImpressions's gallery image in Our Leatherwork Galleries

-

1911 and 2nd amendment holster 3.jpg

LastingLaserImpressions commented on LastingLaserImpressions's gallery image in Our Leatherwork Galleries

Whit30: Thanks for the compliment and comment. I do items for Law Enforcement like plaques and recognition items. I have even done badges and department logos on pistol grips (look at my webpage for examples). I can duplicate those on a holster without too much grief. The mark is much like branding the leather and it smells like money. If you notice I marked the backside of the holster with my logo. That could have easily been a badge and been on the front. If I have a clear picture to work from I can duplicate most any badge or logo. Let me know if you have anyone that might be interested in having this done. Thanks