All Activity

- Today

-

spring flowers and good food

Handstitched replied to chuck123wapati's topic in All About Us and Off Topic

@Mablung former, akubra, newbie, again, statesman. My very first hat was a statesman and is now a museum piece on display in my workshop. My next pair of work boots will from an Aussie company, also not owned by a mining squillionare HS -

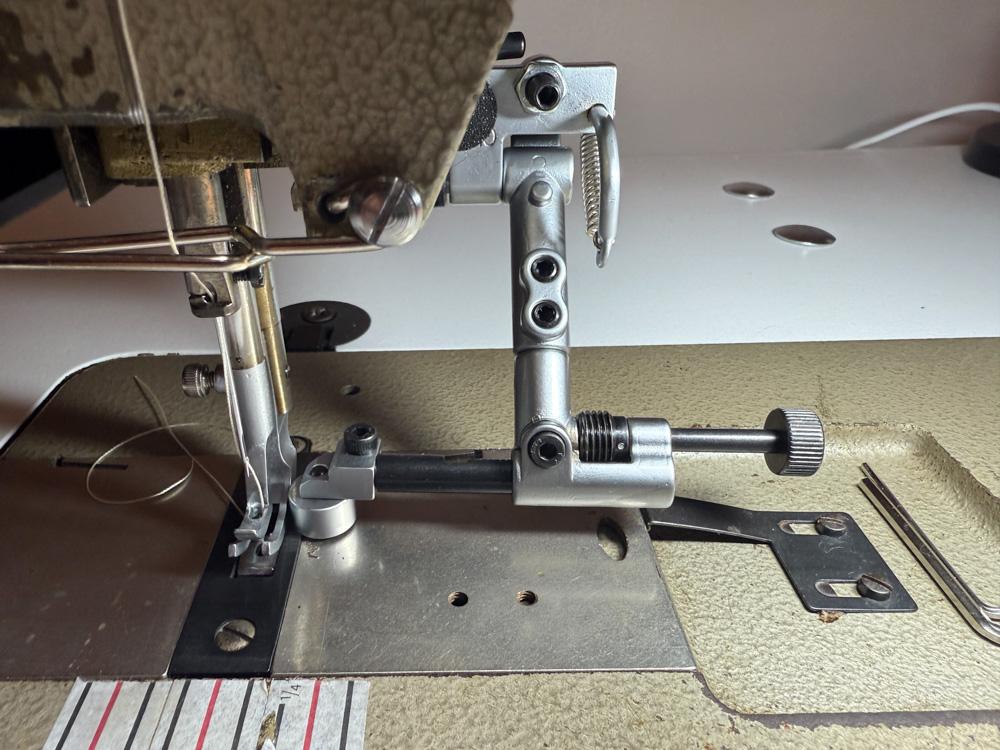

That is correct. It is a walking foot machine and is not a candidate for a roller foot conversion. If you really want a roller foot machine that is on par with you Outlaw stitcher, search for a Singer 45k with a roller foot installed at the factory. Or, buy a modern day clone like the Cowboy cb2500, which can be fitted with a roller foot by the dealer.

-

Some of us, myself included, have machines without reverse. We can either sew all the way around an object and overlap the starting thread about 5 stitches, or tie off the starting threads under the work, or spin the work 180 degrees and perform poor man's reverse to sew over the starting few stitches. As for holding back both starting threads, some jobs render that impossible. A good example is sewing patches onto vests and jackets where you can only handle the top thread. In this case I hold down the top thread behind the presser foot so it doesn't get pulled down into the shuttle during the initial couple of stitches.

-

Thanks for a great deal on these. Make me a deal on that class 20!

-

If the header didn’t give it away, I’m back to my first rodeo… I haven’t worked with fur before. Are there any tips or tricks for working with a rabbit pelt? I’m making Dieselpunk’s elf hat, and I intend to use the pelt for the trim, so nothing beyond basic. I’m just unsure of new materials these days… Thanks, and may you never burn your bacon! — AZR

-

How to prevent overglue?

ThisIsMyFirstRodeo replied to ThisIsMyFirstRodeo's topic in How Do I Do That?

Guess I should add in that regardless of what kind of adhesive, I stitch everything… - Yesterday

-

How to prevent overglue?

ThisIsMyFirstRodeo replied to ThisIsMyFirstRodeo's topic in How Do I Do That?

So I didn’t get the lid closed enough on my cement (weldwood) and while attempting to thin it out with some acetone yesterday, it almost seemed to seize up on me. (Today, it actually looks quite usable though… 😉) Although I was working a different project yesterday (on a timeline), I still had to glue/cement/adhere a few pieces. But, because of the issues with the cement, I wound up using Gorilla wood glue. Seems like it did the trick in a pinch, even if less than ideal. Hopefully I’ll clear my production board so I can move back to my belt and keep going… Thanks guys, AZR -

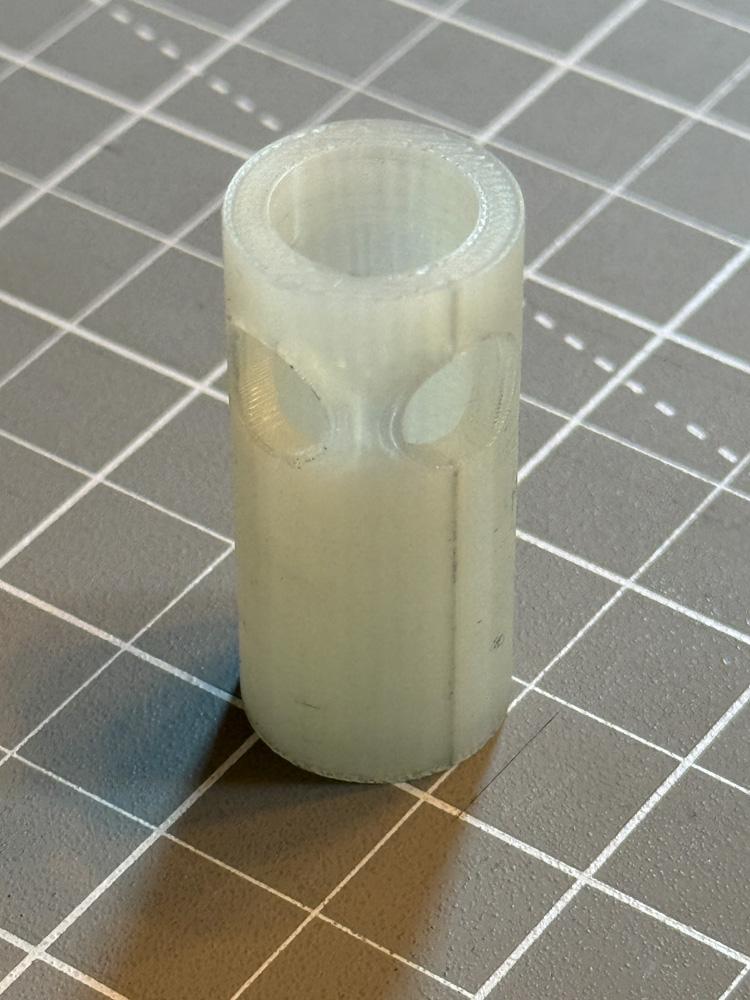

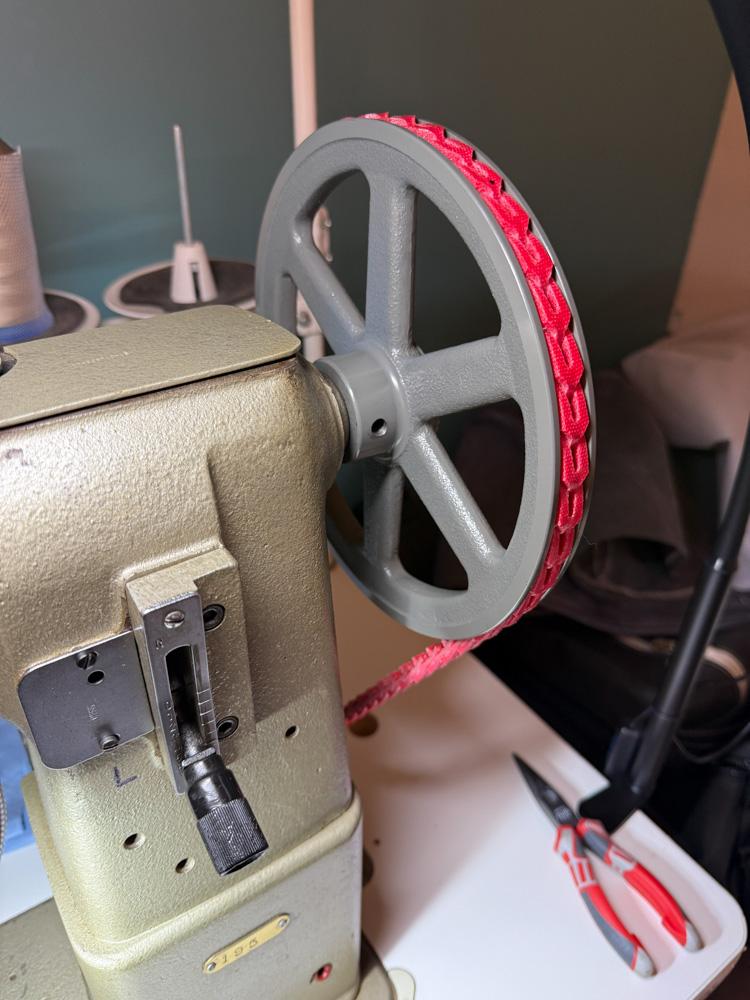

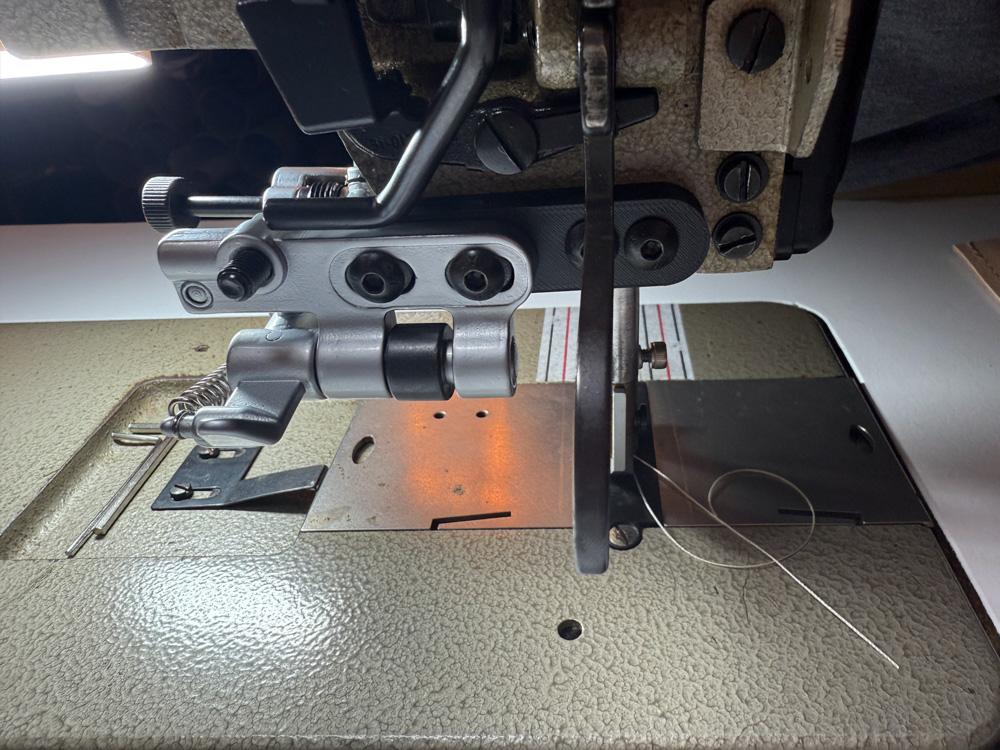

New to the forum. A few basic 3D prints for my Pfaff machines. Basic PLA used. Collar to fit a 3/4" bore 8" cast iron pulley as a larger hand wheel on a Pfaff 195. Pfaff shaft is 0.501", just a little big for a half inch bore pulley so adapted a larger bore to fit with longer set screws. With a brushed servo motor mounted 1-3/4" pulley, I can get as slow as about 20 stitches per minute. Also, bought a generic roller guide which doesn't fit all machines directly. Printed an adapter with brass heat inserts for my Pfaff 1245. I was very happy with how easy this was. Still learning best hole sizing for the inserts. Pfaff 1245 uses M5 threads, used the same for the inserts.

-

Thank you Everything in moderation. The aim is two fold. Even tension and to prevent any excess bobbin thread on the underside of the leather or fabric that would cause a problem. kgg

-

The basics never go out of style. When I was getting started with industrials I took the advice to "hold back hard" to heart and I was splitting the thread on the hook of my 111w. I think that advice was meant for bigger machines. Caused me a lot of frustration until I figured it out. Just gentle pressure.

-

spring flowers and good food

Darren8306 replied to chuck123wapati's topic in All About Us and Off Topic

Ya, this morning I stumbled across a quote attributed to Friedrich Hayek: The other thing is more...um...mechanical. I can have quite a lot of 'success' from grant money, but then how would I know that my work was good quality? I know a lot of people take advantage, and some of those that I know do very high quality work, but there really isn't a leathercrafting community here. The best really clear feedback I can expect is money. The grant doesn't care at all about the quality of my work. At least as far as I can tell from here. -

Starting a Seam in leather or fabric

chuck123wapati replied to kgg's topic in Leather Sewing Machines

nice!!! -

I moved your post to leather sewing machines. This is where the machine guys hangout.

-

The very basics of getting a good seam are: i) correct machine threading ii) correct top & bobbin tension iii) correct needle system for your machine iv) correct orientation of the needle v) correct needle type (ex. 135 x 16 for leather and 135 x 17 for fabric) vi) correct size of needle to handle the top thread vii) This next step is where people seem to be having a problem. Getting the seam started. You really need to hold both the top and bobbin thread as you start your seam. That can be a royal pain grabbing and holding those threads particularly with smaller sized thread like v69 and v92. If you don't hold both together weird things can happen like jams, bird nesting, skipped stitches, etc. A quick solution is: Tie both threads together by a simple knot. Chances are now you will be able to grab the threads and put consistent tension on both threads at the same time. viii) Locking the threads a) Typical method is sew forward 3 or 4 stitches and then reverse to lock the stitches then continue with forward stitching. b) More Advanced Method is start your stitching 3 or 4 stitches in and reverse sew back 3 or 4 stitches. The seam threads will be locked when you sew forward but with less thread bulk in the needle holes. kgg

-

Calf Leather Outlet joined the community

-

This happens with leather also.

-

I have a 545-walking foot machine I was given in pieces and I am putting it together. I am having trouble getting the pressor foot to move up to allow the material to move rearward (away from you) when it is sewn, the rest of the timing is fine I might be missing a part it has got me tossed

-

Thanks Friquant, I'm pretty sure the machine sews ok but the sound raises some concern as it only started after I re timed the hook. Also removing the timing belt is a good tip I wish I thought of when trying to find where the sound was coming from. I think it might be coming from the large timing gear and the small gear on the hook saddle although nothing I do seems to fix the sound (I've tried re timing and moving the big gear to mesh with the smaller one differently a few times to see if that fixes anything but the sound still persists) but I will try messing with the feed dog eccentric as well. I only just got this machine a couple months ago and am pretty new to sewing in general so both you and wizcrafts advice has been really helpful.

-

spring flowers and good food

AlZilla replied to chuck123wapati's topic in All About Us and Off Topic

Good call. I have some experience of grants. My motto, "If you take their money, you give them control". This applies to anyone who wants to contribute to your cause and for all values of "they, their and them". -

That turned out great!

-

spring flowers and good food

Mablung replied to chuck123wapati's topic in All About Us and Off Topic

What company formerly and what company newly, if it's not impertinent to ask? I have a dabbling curiosity (and far less than sufficient money to scratch the itch) in fedoras and bought an Akubra offering a while back. Best value for the money I could find via internet research. -

showoff Sharing one of our favorite recent projects.

Teddy Patches replied to Teddy Patches's topic in Show Off!!

Thank you very much for the reply. If we have any projects related to this in the future, we will definitely consider it. Embroidering on leather was quite challenging—the needle broke multiple times. And yes, the embroidery was done directly on the leather. -

And here is my favorite machine. I try to make more heavier projects because I can do them with my outlaw.

-

Here is the other electric machine that I have. Im guessing the answer is the same for this one as I think it's triple feed which is what makes it not a fit for a roller foot but I'll ask just in case.

- Last week

-

Thanks Tommy. Never even thought about that.

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)