All Activity

- Past hour

-

1: don't use glue . . . use contact cement . . . put it on with a plumber's brush . . . (cheap metal handled / size of a pencil / buy at Harbor Freight in a bag) 2: it goes on both surfaces that are to be put together . . . let it get 95% dry . . . then put them together. 3: a minimum amount of care will keep it off where you don't want it. May God bless, Dwight

-

Welcome to the forum. Not knowing the history of that piece makes it tough It might be that it had something applied or spilled in those spots that prevents the conditioner from soaking in. It might evaporate with time. Maybe some time sitting out in the sun? How about a picture? Smarter people that I will certainly weigh in presently. Don't be in a rush.

- 1 reply

-

- conditioner

- repair

-

(and 1 more)

Tagged with:

-

One of the biggest temptations is to jump right in and start making more complicated pieces, before we have the knowledge and experience. It's a very common thing for beginner leatherworkers -- most of us have done it! One thing that will help you learn is good leather, especially if you want to learn tooling. Cheap leather will be frustrating, but you don't want to spend a lot of money on beautiful expensive leather yet (until you know what you are doing). So there should be a mid-range that will let you buy leather that you won't mind throwing away on practice pieces. Is there a leather supply store near you?

- Today

-

It is. Been posted before. Still fun to post.

-

Great cats. Cute, for sure. Consistent quality from one to another. Nice shading on the backgrounds, too.

-

Thanks I'll give one of them a try and for sure I'll post the goal.one day will be making batman mask I saw once at a ren fair .

-

Hey, if you ain't bleedin', you ain't tryin'. Nice work.

-

The Odd Platypus joined the community

-

BerlinAir joined the community

-

Hello, I got a used leather purse; soft leather, pink in colour. I used the honey leather cleaner and then next day used the honey leather conditioner. I accidentally got some large spots (size of palm) with too much conditioner and its been 2 days. The spot is very noticeable. Looks greasy/wet. Not sure if I should used the cleaner on the spot that it not absorbing the conditioner and start again. Thanks

- 1 reply

-

- conditioner

- repair

-

(and 1 more)

Tagged with:

-

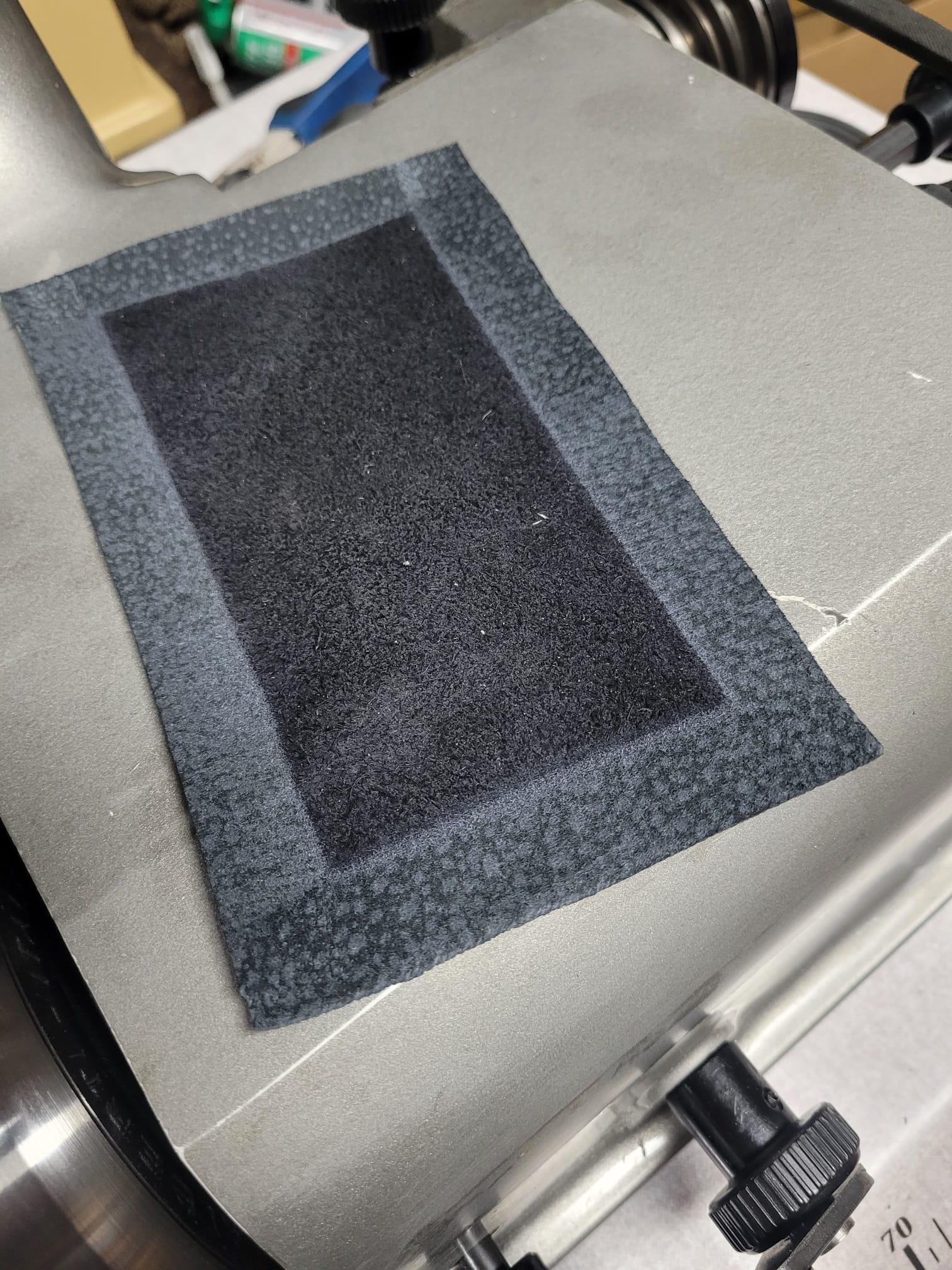

Hey all, So I’m making a padded belt, but I’m wary of getting cement on the face/grain of the strap. Is there a way to protect/prevent it? I had the thought of just masking it off with tape, but in the past, tape has seemed to deglaze the grain. Thoughts? Thanks, and may you never burn your bacon. — AZR

-

I purchased this skiver 20 years ago and am now just putting it into use in my shop. I found the Catalogue and Price List of Parts but am looking to see if there is an operating manual available or has any knowledge of this machine. Obviously needs to be cleaned up which I plan to do. All parts are moving freely despite any obvious corrosion. Bell knife has section of surface rilusrlt on the portion that was facing the presser foot while in storage and hopefully I can just clean that up. Blade edge looks fine. Any help or hints greatly appreciated.

-

Thank you for the advice Wizcrafts. The sounds still persist even with the case opener off so I might try fiddling with the gears more.

-

Teddy Patches joined the community

-

Hi guys. I bought this machine for myself but honestly my space it s getting very small with it inside. I already have a FAV2 from the 80's that I rebuild myself and that s without a vacuum so takes little space. I prepared it like I do for my machines... Anyway, regarding the ad. Price is 1200 eur, excl shipping. from Romania. But I can arrange the transport inside the EU aprox for 250 eur. Machine model is FAV2 MA from 2007. Rebuilt by me with original FAV parts. And cleaned the table and drawers. The machine features a separate motor for the grinding device which is really awesome because it sharpens the knife so nice! The only thing that it "has" : the transport roller shaft, where the clutch is was shortened/grinded by the prev owner to have the clutch engaged all times - which is so stupid because you can actually use a screw that locks that in place. Anyways, in order to make it work again, I just used a washer in the clutch cap, where the clutch disc is, so I can compensate for that difference. In terms of function, it doesn t have any issue like this. VIDEO: What I replaced: - replaced all of the bearings except the oscillating one inside the transport shaft. That one is fine. - the cardan shaft - the articulated shaft that connects the gears to the roll. The older one was done - new transport roll and its shaft - new FAV knife with new grinding stone ofc - new gears - new grinder belt and new transmission belts. - new presser foot - new grinding device shaft, the one where the grinding stone is attached to - new rubber coupling . The piece that connects the knife shaft to the pulley Like I said everything works like new and skives really really nice. It comes with its manual and a thickness caliper and a scrap ejector rod made by me Machine is 380V but if you need to I can prepare it for 220v but the VFD s are on your expense...those cost quite a bit.

-

richwebb8 joined the community

-

That looks strangely familiar .....

-

Juki 1541s feed dog and walking foot

CowboyBob replied to Scifidelity's topic in Leather Sewing Machines

When we sell one of these we always buff off the feet if they are sewing leather & do the same on the Consew's too.They don't mark then.AFAIK there are no smooth feed dogs for them. -

-

Juki 1541s feed dog and walking foot

Scifidelity replied to Scifidelity's topic in Leather Sewing Machines

You are correct, the feet are smooth. However, the dogs are very serrated. -

I have one Singer 18-2, that is ment for different job shoes, slippers etc.. I want to keep 2 main machines. One being the Singer for its purpose(shoes, slippers etc..) Second one for flat surfaces wallets, bags.

-

Try listening as you handwheel the machine. It kind of sounds like gears are grinding from being too close together. I might also be the opener arm pulling the shuttle all the way back with a hard stop. There must be a little clearance when the arm pulls the tab back.

-

Hello my friend. Im only posting because i see nobody else has replied lol. But I have always wondered the same thing. There is a fella on tiktok named blackwater leather that does a ton of console covers that are really beautiful. You could try getting a hold of him for some insight, if you mess around on tiktok at all. Also you could try and post something in other forums so maybe someone more knowledgeable than myself may see it. Good luck!

-

Got it👍 Thank you again

-

Cowboy 4500-Consew 206RB5–Claes 20 Patcher(central PA)

OldNSlowMarine replied to billymac814's topic in Used

The Cowboy 4500 still available? Please send email to jasoningle@inglegunleather.com if it is. -

Maybe you could post that kit you found and get some opinions. They're are a bunch of them. Here's a post by a guy doing some amazing work with a $50 amazon starter kit: https://leatherworker.net/forum/topic/125186-leather-projects-using-50-dollars-of-amazon-tools/#comment-771141 Maybe it'll give you some inspiration. Keep us posted as you progress!

-

I started out with a leather kit from Amazon. It was like $140 & had all the basic tools to get started. Plus it had 4 colors of thread, beeswax plus some other stuff. I made a lot of stuff with that kit.

-

Quite nice, I think. I appreciate the fact of the natural creases in the non-carved face. I like my items to look like the genuine full grain leather they they are, just like the animal wore it. Well, dye, finishes, etc. are fine.

- Yesterday

-

Hello, I am in Washington state and I would like to commission someone to do a few things 1_convert a fanny pack i have into leather using an industrial sewing machine similar to mine 2_create a pattern of that fanny pack 3_digitize that pattern 4_make a video or a series of videos of themselves making the fanny pack, documenting each step and process 5_teach me, whether that's me going to your house, or you to mine, how to make this fanny pack, myself on my machine, start to finish, is there anyone in Washington state that could do this for commission? thank you

.jpeg.e4e7a9501f229793c202ae69a1173ae1.jpeg)

.jpeg.9f1677283bacae864e5bf55d8c4a8c31.jpeg)

.jpeg.209c2a4e77f6bd9216aa41a1c5523e7e.jpeg)

.jpeg.041f554a3936cfaca83d6591ee69f226.jpeg)

.jpeg.62476addf24d37d6ec13c1a6247cbeb3.jpeg)

.jpeg.293d6a4b06548f9ec1fcc36e042ff0b3.jpeg)

.jpeg.c4dd47a5911dc7355f5788d695983c30.jpeg)

.jpeg.84bc5afdaa530da2842082c6c25d4fec.jpeg)