All Activity

- Past hour

-

This is a home made knife, slightly larger that the Tandy round knife. This blade actually cuts as well or better than my commercially made knives. Ther4 handle can be replaced by pretty easily. I just never had the need. Comes with the slide on cover shown. $40 plus shipping.

-

This knife is in good condition and is very sharp. It has no name on it, but looks like a clone of Tandy's Stohlman knife. $45 plus shipping.

-

I have 2 of these that have little to no use on them except for stopping. $50 ea. plus actual shipping costs.

-

Yes and No. My two cents: i) Looks like the cooling fan is incorporated in the motor pulley. So getting a smaller motor pulley with the cooling fans maybe limited. ii) Appears to be a 550 watt 6 coil brushless servo motor which would probably work. A 12 coil 550 watt would be better but would cost more (2X). iii) The start up speed could be as high as 500rpm which will give you startup jerk. A speed reducer would help eliminate that or go with a brushed servo motor rather then the brushless servo motor. iv) Make sure the operating manual comes with the setup. v) Like @AlZilla has mentioned the control box is going to be in a awful location under the table so you are going to be down on your hands and knees to change the settings. kgg

-

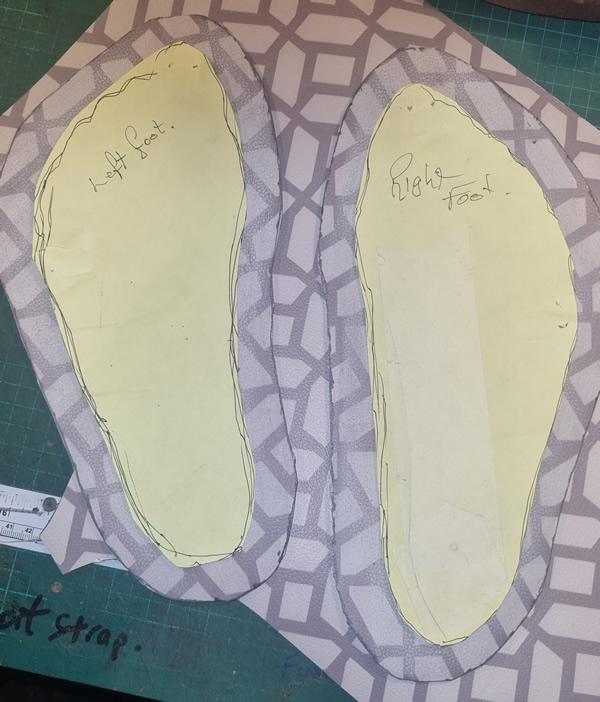

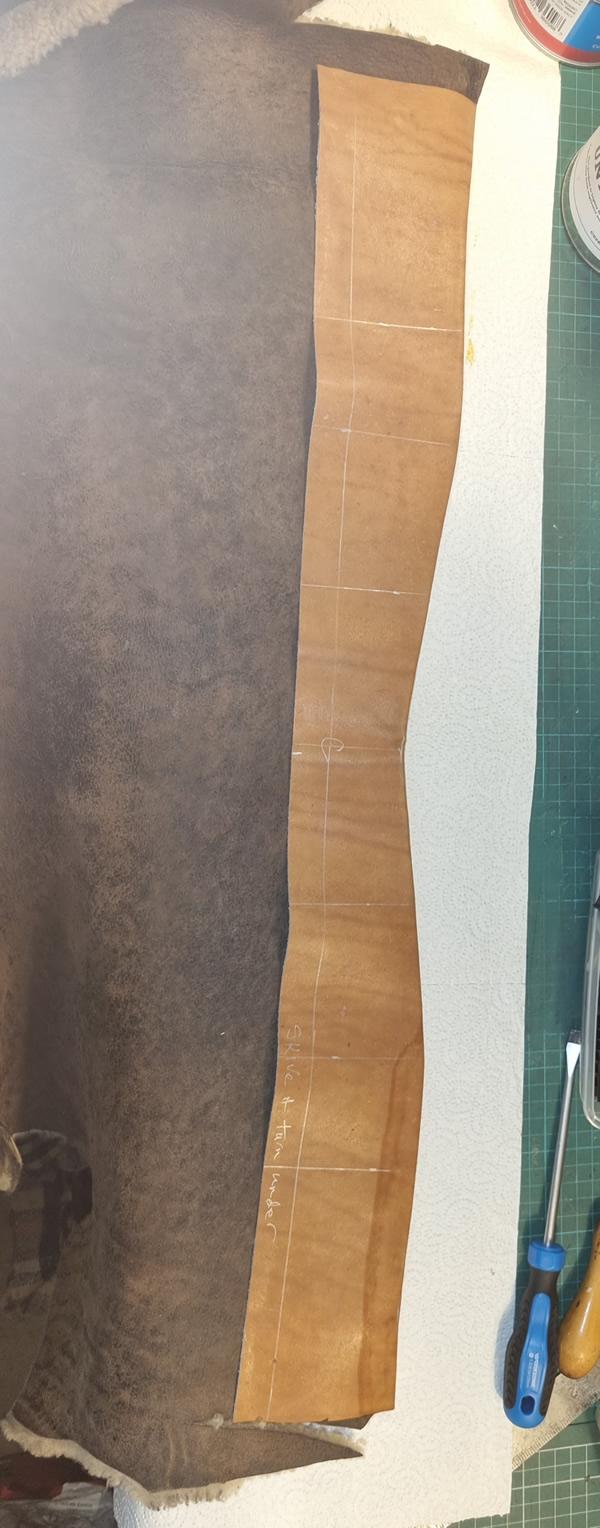

Been threatening to have a go at slippers for quite a while because I have the leather and a bit of sheepskin and at the moment I'm stubbornly walking on holes. I couldn't find any cheap outsoles and I found a cheap vinyl mat with a good textured back and I immediately thought glued back to back would make a decent sole for a pair of slippers. Draw around feet and cut out. Oversize because I intend to make things easy by sewing and binding around the outside. Rough up and glue. Work out the shape you want. I was very pleased that the 801 skiver took the sheepskin in it's stride. Top level glued and turned. Feet cut out. First try for fit. Cosy or what? That's where we're at now. More to follow.

- Today

-

I have never seen anything like that - I have no clue! 🤔 I´m not questioning the quality of Pfaff machine but Pfaff IMO made a lot of thing way tooooooo complicated. It it was a Singer 236 I would have a belt driven roller foot.

-

@Mocivnik Moved your post to Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners. And to comment on NFO, it is a conditioner used to replace natural oils lost due to dyes and other treatments. It is not a finish. Also finishes (acrylic or lacquer) seal the surface of the leather. It helps prevent loss of natural oils, fats, etc. and blocks addition of oils, liquids, and other stuff that may damage the permanently degrade the appearance of the leather. It can wear off if the article is subject any type of abrasion over time. So a wax is often used to protect the finish and is normally buffed to remove any excess.

-

Reommendations for Getting into Saddle Repair

BlackDragon replied to Samer's topic in Saddle Supplies, Tools & Trees

Be very careful when repairing a saddle. If a shoe repair fails a person will walk funny for a little bit but if saddlery fails it can lead people to severe injuries. If a stirrup fails a rider can slip or completely fall out of the saddle, if a billet strap fails the rider can wind up under the horse. With that out of the way since you've done some repairs you know a little bit about it. What I've done is bought some cheap saddles. I bought 3 saddles for $150 at auction and I tore the worse of the three apart to learn how it went together and to experiment. I highly recommend Don Gonzales' videos, he gets really in depth with his breakdown and repair videos. TomE makes good recommendations. Also look at some of Springfield Leather Company's video on saddle reconstruction. There are a few videos out there that are horrible for saddle repair so be wary of those. One says she is a master class cobbler but the repairs she make on an English Saddle are really... bad. -

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Reommendations for Getting into Saddle Repair

Northmount replied to Samer's topic in Saddle Supplies, Tools & Trees

Updated the title to represent the actual topic. -

Reommendations for Getting into Saddle Repair

TomE replied to Samer's topic in Saddle Supplies, Tools & Trees

As you no doubt know, English saddles and western saddles are 2 completely different items in terms of materials and construction. There are a lot of resources and classes for western saddle making, which will show construction methods that are relevant for repairs. I'd start with the Stohlman's Encyclopedia of Saddle Making from Tandy and also check out books and DVDs at the Leather Crafters Journal online store. Fewer resources available for English saddles. Robert Steinke's books on repairing harness and saddlery are good if you can find/afford them. Joshua Siegel is a skilled saddler in western MA who might be a resource for you. Also, the Facebook Saddle Restoration group includes some skilled saddlers (scattered among many saddle cleaners/flippers). Jack Stewart does saddle repairs for Stubben North America and is a helpful member of the restoration group. -

landis 5 in 1 Landis 25 - Landis 5 in 1

JayEhl replied to GraceAVD's topic in New and Refurbished to Like New

Yo, beyond the meticulous paint job I enjoyed the pictures. And the Christmas decoration was an added touch! ~JL- 1 reply

-

- landis

- landis model 25

-

(and 2 more)

Tagged with:

-

According to the parts books like it's an "Oil Regulating Screw" - whatever that means! - Bill 255RB-3.pdf Consew255RB-3 parts & opermanual.pdf 255339LSW2BLLSW28BL.pdf

-

Thanks again Dwight, but no. It's toast. The laptop fell from a table while powered on. I opened the HDD and there's a hard physical crash on the disk surface. I've recovered drives from a minor head touch, but this one you can see bare aluminum through the substrate. - Bill

-

Reommendations for Getting into Saddle Repair

DieselTech replied to Samer's topic in Saddle Supplies, Tools & Trees

Check out Don Gonzales he has physical classes. & might offer online classes as well. -

Reommendations for Getting into Saddle Repair

Samer posted a topic in Saddle Supplies, Tools & Trees

Hello folks, I have a Shoe Repair, I have done little saddle repair work. I’d like to get into the saddle repair service. And you recommendations where to start and what to get for startup tools? Are there any online schools? Any comments or recommendations are appreciated. Sam -

Calvin & Hobbes in today's paper: 'Mum and dad quietly sitting and reading in front of the open fire . Calvin, getting ready to chuck a snowball: " Incredibly, people NEVER expect to get hit with a snowball IN the house " Hobbes, casually walking away : " I'll see you in your room momentarily " . That's the sort of thing I would have done when I was a kid,if only we had snow. That had me in stitches! Incredibly, 4th year students on the 3rd floor of my high school doing their exams would never expect to get splattered with a rotten tomato . It wasn't me, honest, it was a naughty fellow student. Instead of the tomato going IN the window, it caught the edge of the frame , spraying the students. We got busted big time ! ! HS

-

Latigo Smith joined the community

-

Will this work for a singer 111w154 ?

AlZilla replied to outaluck's topic in Leather Sewing Machines

It will But you may want to find a version where the control box is separate from the motor. This way the controls can be mounted at the edge of the table where you can play with them. The style you show would require you to climb under the table to tweak any of the settings. -

Best way is to fit a speed reducer pulley as well.

-

I can’t find a manual for the 255rb-1

-

Will this work for a singer 111w154 ?

outaluck replied to outaluck's topic in Leather Sewing Machines

Dam lol looking to slow it down -

Will this work for a singer 111w154 ?

Constabulary replied to outaluck's topic in Leather Sewing Machines

it will but depends on your expectations regarding sewing speed. You may need a smaller pulley or speed reducer in addition. -

what does the manual or parts list say? I`d guess a drain screw or oil regulating screw for the hook.

-

-

spring flowers and good food

Darren8306 replied to chuck123wapati's topic in All About Us and Off Topic

I usually make a mess of contact cement. These were better. By a lot. I have a syringe to fill them from a can (kept in the house) and bring one or two of these small glue pens out with me, into the sometimes-frozen leather shop (and radio lab) Anyway, cheap Temu find if anyone wants to try some. -