All Activity

- Past hour

-

Adventures in watch strap making

AlZilla replied to dirk87's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

That multi-punch tool you show is meant to stop on the lower anvil. I could see the soft veg tan keeping the cutter from cutting cleanly. Wear and tear on the cutter is just part of using the tool. That tapering effect you get is really the nature of the tool, probably exaggerated by the very small size. I've often wondered if anyone makes a straight sided punch. -

Anyone taken a cheap servo motor apart?

AlZilla replied to AlZilla's topic in Leather Sewing Machines

No, definitely not a belt. It makes a small winding/grinding sound with no belt. A belt makes it worse and more tension increases the noise. To @chuck123wapati's point about the fan, even if it isn't a bad fan, I'm going to dig up a small 5 VDC computer fan, point it into the motor housing and plug it in to the LED socket on the control box. One thing consistently said about these things is that they make heat at low speeds, exacerbated by the fact that the fan is running slowly. That should be easily solved. - Today

-

Anyone taken a cheap servo motor apart?

chuck123wapati replied to AlZilla's topic in Leather Sewing Machines

i've seen electric motors break the fan blades located in the rear of the housing They make quite a racket sometimes, i dont know if your motor has one. the blades are usually plastic and can come loose or break. -

Janis ROCKS!!!!! I love it, she is an awesome artist indeed.

-

Anyone taken a cheap servo motor apart?

Cumberland Highpower replied to AlZilla's topic in Leather Sewing Machines

Just a thought, but if your pulley doesn't wobble and the shaft appears to have no runout, is your belt having a bad section? Just thinking of all options. -

I'd have to agree with the acorns and leaves being a poor mix with the geometric pattern... But... It was a request from the end wearer, who wanted a nod to the Major Oak in Sherwood Forest (Robin Hoods tree) which is only a stones throw from my workshop and her home. As the Selfridge saying goes, "the customer is always right, in matters of taste"

-

@Sblof Just to add to @Wizcrafts info the 135 x 16 needles would be for leather and the 135 x 17 would be used for fabric. An example would be for using V138 thread sewing leather you would need to use 135 X 16 X (size of needle) so you would need 135 X 16 X #23 or #24 depending on the thickness and toughness of the leather. Here is a good chart for selecting needle size for thread size: ( https://www.tolindsewmach.com/thread-chart.html ) kgg

-

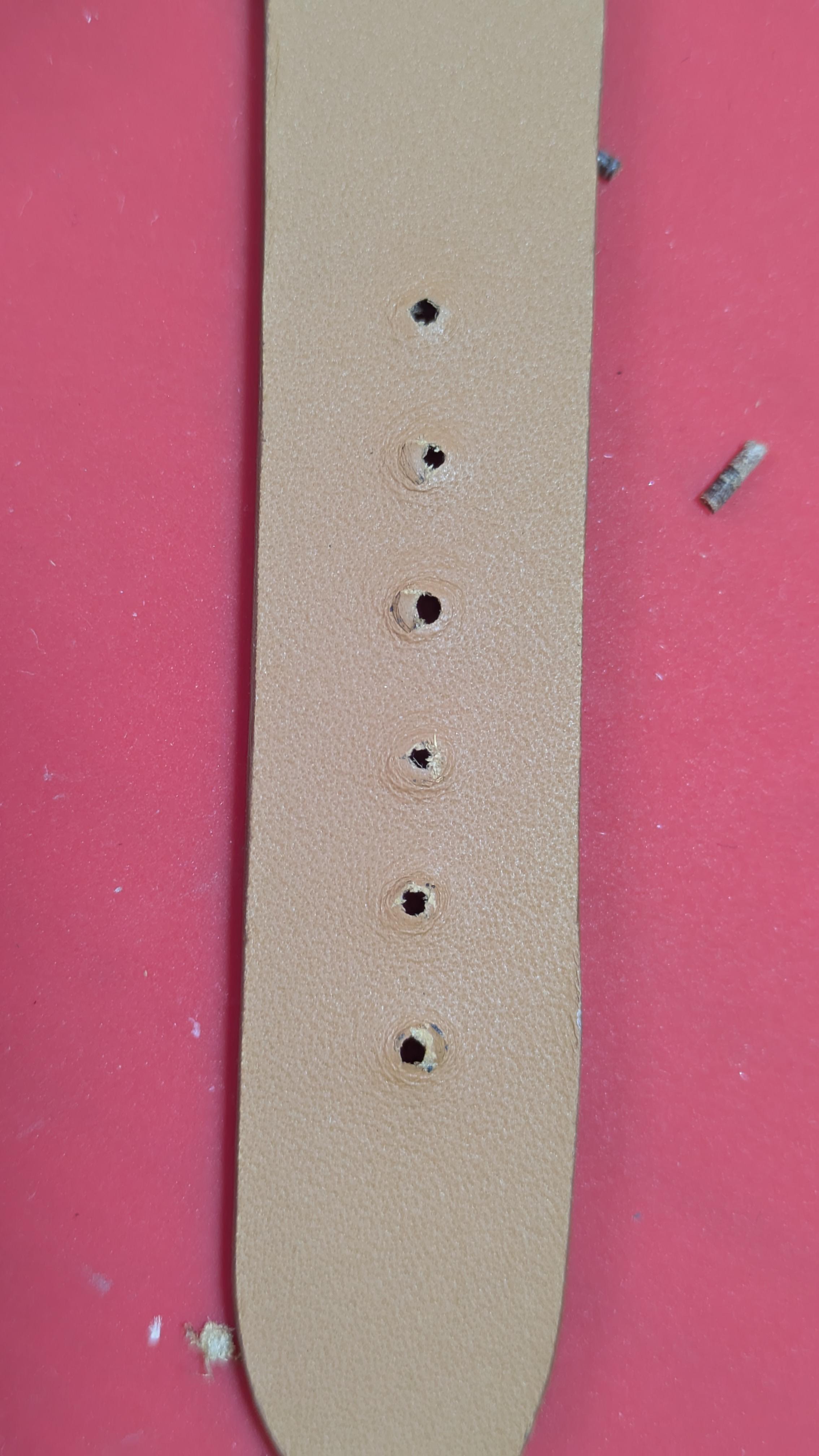

I'm having trouble getting a clean cut on the lining side of my straps. I use 1.0mm Zermatt calf waterproof leather, making the hole with a rotary hole punch tool. I use a 1mm piece of veg tan leather underneath the strap so I don't damage the punch tip. Maybe the punch is wearing down. I've tried using single punch tools but even my 1mm makes holes that are much larger than that due to the tapering of the tips. Anyone able to suggest why my holes don't come out more clean on the Zermatt lining? Very nice work!

-

@Sblof Your Nakajima 280L machine has been discussed on these forums, before. Here, here and here. It is a compound feed walking foot machine. It uses the common System 135x16 and 135x17 needles. It takes all manner of Singer 111 style feet. Most are smooth. It was a forerunner of the current Juki 1541.

-

I looked at her entire site and that never happens. Amazing work.

-

Welcome to the forum! How about some pictures of the Nakajima, and of the new motor?

-

Anyone taken a cheap servo motor apart?

AlZilla replied to AlZilla's topic in Leather Sewing Machines

Hmm... I'm anxious to take it apart. The pulley doesn't wobble. I'm surprised nobody has taken one apart but I can't find anything online. Yet. A week or two, I guess. -

Merritt joined the community

-

I recently got a Landis 16 . I'm having problems getting the stitching to be consistent. It will have great stitches for a couple of inches and then the bobbin thread doesn't pull tight. I also have had problems sewing shearling to the skirt ?

-

Ha! Sorry about that, I think you got the picture but I'm referring to the motor pulley on the patcher. I've spent some time looking it over, along with the engineering diagram I have (in German) It appears that everything on that shaft is pinned and has a sew screw so I don't see any opportunity for adjustment. I did pop the pin on the aformentioned pulley and tapped it in further which does take up the slop but without the pin that's not a long term solution. At this point I don't believe there is any solution within the machines available adjustments but the "clunking" is going to get annoying. So I think I'm going to pull off the pulley and insert a couple nylon washers. Not so much that it's tight and binding but enough so that it has minimal travel Thank you for all the pictures! It really helped identify some of that parts and what I should be considering when finishing the setup. I went ahead and ordered a servo motor and speed reducer. I'll have to make a couple custom mounts but for the most part I'm happy with the progress and plan. I looked at the plate again, it was made in '81 I'm not sure what engraving on the base you're referring to. The serial number plate on the machine says 8346/30. Now that it's sewing well and I have some more background info I went ahead and ordered a servo and a speed reducer. Other than my concern about the main shaft's horizontal movement (and the associated slop in the hand crank's spider gear) I think we're on the right track!

-

Some exotic inlay for 1911

Yellowhousejake replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Gotch ya. Thank you. DAve -

Anyone taken a cheap servo motor apart?

Cumberland Highpower replied to AlZilla's topic in Leather Sewing Machines

Sounds like a bent shaft, but could be a bent pulley as well? I doubt it a bad bearing though. A damaged bearing would make a rumble or a bit of vibration from the brinelling caused by the impact but that's about it. -

https://cindysinorartist.com/ Cindy Sinor is a talented colored pencil artist and accepts commissions. I thought you’d enjoy looking at her work.

- Yesterday

-

Anyone taken a cheap servo motor apart?

dikman replied to AlZilla's topic in Leather Sewing Machines

Regarding the control box if it's the same brand and the menus/settings are the same then there's a pretty good chance they will be interchangeable. The motor, being cast alloy, may have a broken bit of the housing inside? -

Yep, they had to develop a magnetic stainless steel so saucepans could work on induction cooktops. Regarding the cheap tool if you file off the corner a little if it's chrome you'll go through it to plain steel, but I suspect it's probably ss.

-

Still playing around , this is rubber tubing contacted to the leather arrowhead . It has quite a bite on the thong , if the contact holds up this will be how I do them . I know slides are cheap but so am I

-

Something was nagging at me, finally figured it out - the geometric designs mixed with leaves don't seem right to me? Having said that, it really is very nice work and if given the chance that colour should age well. My first effort was boringly plain in comparison.

-

I have an inexpensive, generic servo motor that got damaged in transit. The seller credited it back and told me to keep it. Once the replacement gets here, I'll get it off the machine and take it apart. The motor works but rattles and thumps. The tighter the belt, the louder. I'm thinking a damaged front bearing (the damage was a very hard shot to the pulley area that drove it through the styrofoam and cardboard). Also, how interchangeable are the control boxes? The wiring and pinouts of every one I've had my hands on is the same. I'm thinking maybe a higher rated box, say 750 watts, might be ok running a 550 watt motor?

-

Currahee Leatherworks joined the community

-

Recommend finding a store with a range where you can rent what you are considering buying. What feels good in the hand, may not feel as good when you actually fire it. Definitely recommend training. Once you have the firearm, training, and compliance with your state laws you can look for ways to carry. If it's not comfortable when you shoot, the inclination to practice decreases.