All Activity

- Past hour

-

We're always our own worst critics. Welcome back to the obsession. Your work looks great.

- Today

-

heck yeah thats cool. did you try using just a file at slow speed? I do brass but havent tried copper.

-

Welcome again and good luck with this venture. I looked at the website and I'm wondering if it's correct that shipping is free? I threw a couple things in the cart and it says Free Shipping, unless I just didn't go far enough.

-

Very nice, especially your stitching.

-

Hello from near Nairobi, Kenya – New Member Intro

Bobs Brassware replied to Bobs Brassware's topic in Member Gallery

@OdinUK Hi Paul, Apologies for the late reply — I’ve been busy with the website. Thanks for the compliment! Sounds like you're off to a great start with your propane furnace and aluminum scrap. It's a great material for practicing sand-casting. Take your time with the molds, and best of luck with your practice! Looking forward to hearing how it goes. — John Bob’s Brassware -

Hello from near Nairobi, Kenya – New Member Intro

Bobs Brassware replied to Bobs Brassware's topic in Member Gallery

@Darren8306 Hey Darren, Apologies for the late reply — I didn’t see your message sooner! I’ve been busy building the website for Bob’s Brassware, but I’m back now. Thanks for the suggestion about the lost wax and lost PLA methods — it’s something I’ve been looking into. 3D printing for casting blanks is a really cool idea, and definitely something I’d like to experiment with down the road. Right now, I’m focused on perfecting the sand-casting process, but I’ll keep you updated as I try new techniques. Appreciate the insight! — John Bob’s Brassware -

Hello Leatherworkers, Some of you might remember me from Origibelts, where I used to make handmade leather belts. As I looked to expand my product offerings, I realized Origibelts was too limiting — I wanted to create more than just belts. So, I began hand-casting my own brass buckles and fittings. What started as a way to meet my own needs quickly grew into Bob’s Brassware — a line of hand-cast, solid brass hardware made in small batches here in Nairobi, Kenya. Each piece is poured, finished, and polished locally using traditional sand-casting methods — designed for makers like you who appreciate quality and craftsmanship. To celebrate our launch, all pre-orders will come with a small gift of Kenyan coffee — roasted locally as a way to share a taste of the country where your hardware is made. ☕🌍 You can check out the full range at bobsbrassware.com. If you have any thoughts, suggestions, or hardware requests, I’d love to hear from you! Thank you for taking the time to read — I’m looking forward to connecting with you all. — John Bob’s Brassware

-

The frame completes it.

-

Thank you, the one with Billy Bob Thorton was real good too. Would love to see it in person. Wishing you peace beyond all understanding

-

Thanks, It is about 50 miles from me and priced at $1,500 not much info in the ad just says ("Very few hours, comes with extras"),most of my projects ( except a few harness repairs that are closer to an 1" thick) are just under 1/2" thick and I usually do a saddle stitch with the Ritza 25 Tiger Thread, 1.0 mm Ok thanks

-

HI, I purchased a USM clicker press in fine working condition a few years ago. The seller lowered the swing arm to the table for transport. I wasn't there to see the process. Now I'm in the process of putting the machine into service, and I can't figure out how to raise the swing arm, prior to starting the machine. During storage there is some slight corrosion on the the vertical column. Thanks in advance Ragnar

-

Engelus joined the community

-

NFO and dyes

TonyV replied to ThisIsMyFirstRodeo's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

A light application of NFO the day before dying helps restore moisture to the leather, which helps the leather to take the dye. When the dye is dry, buff it with a clean rag before applying top coat. -

@Cwagz396 Start your own topic, post close-up photos of the hook. Also post photos of the entire top thread path from spool to needle eye. We will help you figure it out

-

Lookin good . . . saw Fess Parker as Davy Crockett at the Alamo as a kid . . . never made it, but always wanted to visit the place. Thanks for the picture . . . keep up the good work May God bless, Dwight

-

Hi there? I live in Korea(South) No.19 'Landis 5 in 1' is available?

-

Very nicely done. It would also be good for hammering down the thread in seams. kgg

-

Bernina 217 6mm to 12mm zig zag

nylonRigging replied to AndreaIbis's topic in Leather Sewing Machines

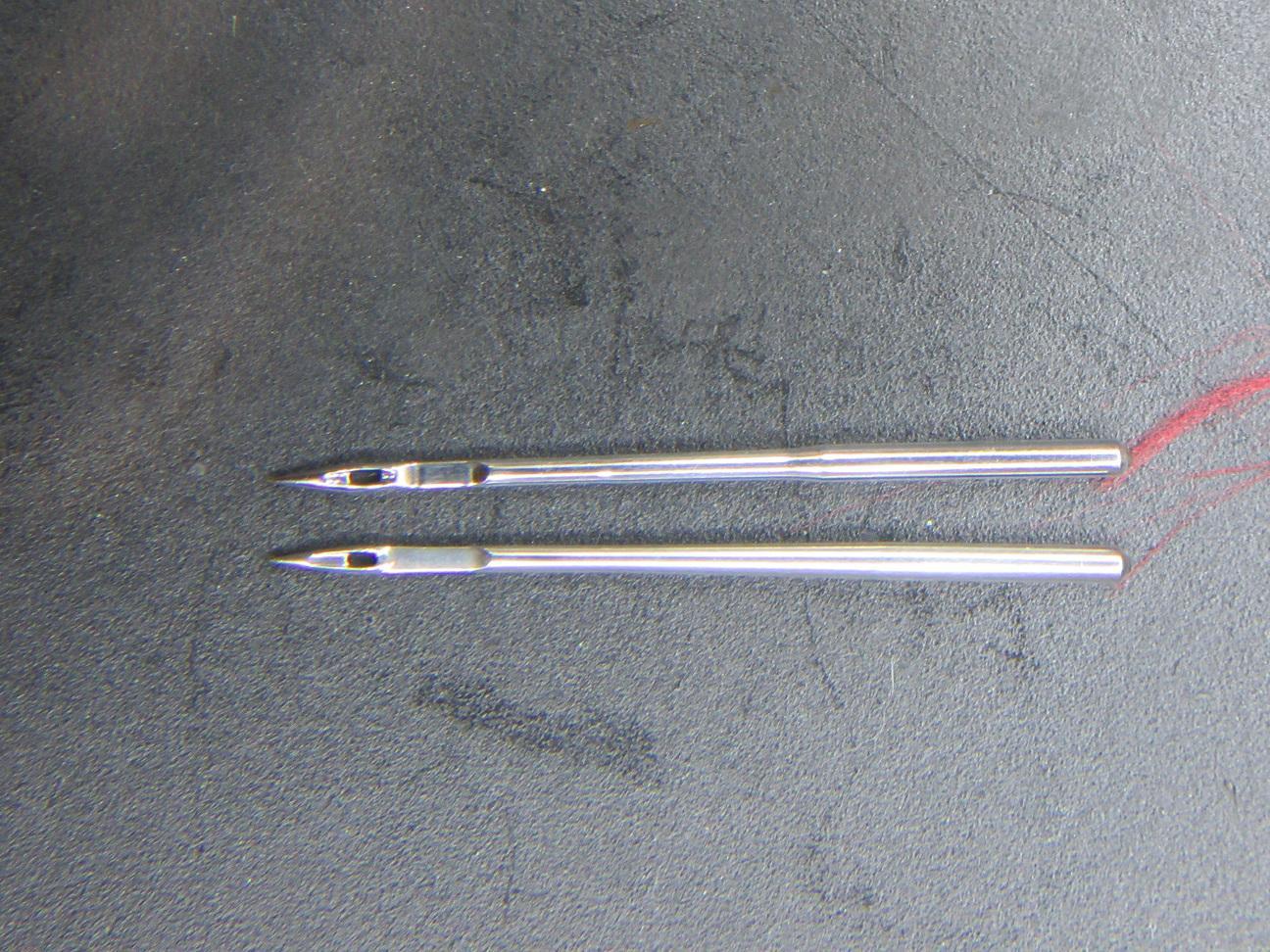

Was thinking you might check the Needle scarf size ? , Shorter length Scarf limits Hook travel, and some needle manufactures have longer length Scarf . Longer Scarf, the Hook will be able to move past the top and bottom of Scarf in little wider path on each needle stroke . Wider Scarf also lets you get more ZZ width without tapping top and bottom of the Scarf with the Hook, and help stop Hook wear. - - -

Wanted to try a building, The Alamo seemed like a good project. It was more difficult than anticipated, larger size would make it easier. The size was 7.5 x 10, seemed big enough when printing the piece, plus it is hard to find a lot bigger piece on a belly. With the price of bellies it gives me more freedom to try and not be afraid of the cost of failure, just have to read the leather for proper moisture content.

-

I posted a 4-month review here: https://leatherworker.net/forum/topic/131750-review-of-jianglong-341-after-4-months/#findComment-784187

- Yesterday

-

Thank you!

-

I made this primarily to use with my lathe but it may be useful for working on sewing machines etc. Copper face one end, nylon the other, copper was melted from motor windings. I found that copper is a pain to turn in the lathe as it galls and creates a rough finish!

.thumb.jpg.327685d8c1787fa894323fed9a6b2dac.jpg)