All Activity

- Past hour

-

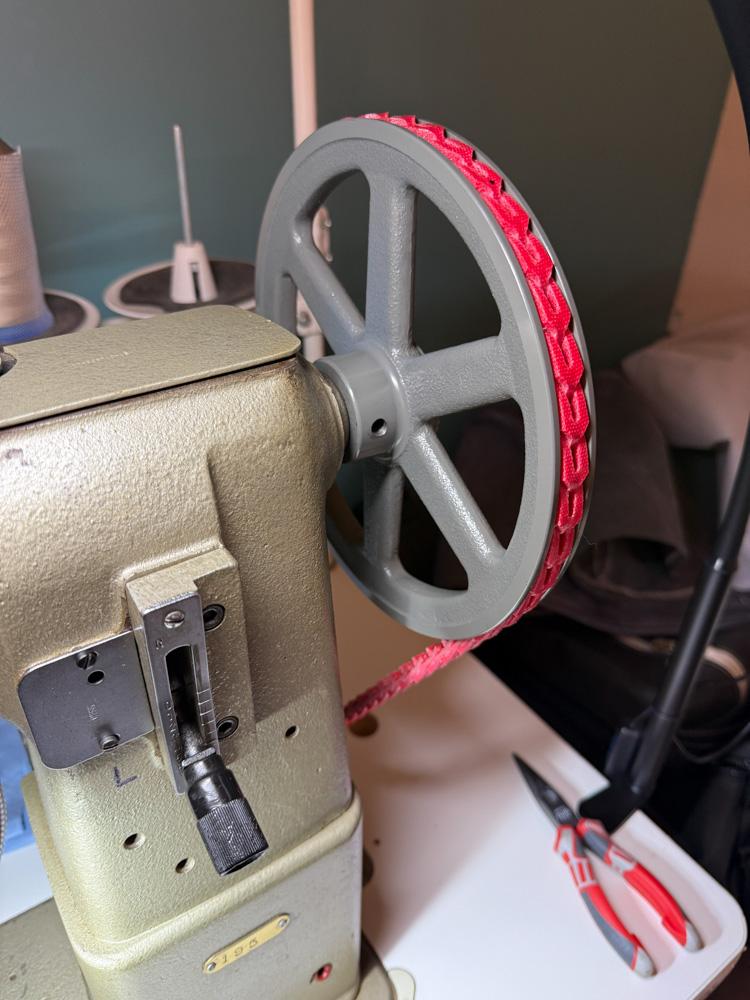

@Darren Brosowski told me once you could put a domestic sewing machine motor on an industrial sewing machine, as long as it was not a walking foot. Here is my journey with that. Singer 31-15 245mm machine pulley Several wood screws were used to hold the plywood to the hand wheel. A round-tipped grinding tool was used to put a groove in the pulley for the belt to rest in. The belt is PU (polyurethane). And here's a video.

-

Need recommendations for steel bar plate for work bench

desullivan replied to desullivan's topic in How Do I Do That?

Just found 4x6 inch plate 1" thick on ebay that was sandblasted already and pulled trigger on it. I will try the metal polish to keep it from getting surface rust and wipe it down before use. - Today

-

Need recommendations for steel bar plate for work bench

CNHLeather replied to desullivan's topic in How Do I Do That?

I use a piece of rail as an anvil i sanded it down and painted everything but the top i sanded and polished the top with metal polish and wipe it down every time I use it and it hasn't rusted in the 4 years ive had it. -

Need recommendations for steel bar plate for work bench

bruce johnson replied to desullivan's topic in How Do I Do That?

Check with a local steel yard if you have one close by. Sometimes you can get off cuts from the scrap. -

Need recommendations for steel bar plate for work bench

desullivan replied to desullivan's topic in How Do I Do That?

Thanks Bruce! Now I know what to look for. I will try and find one or find steel plate that is similar. -

spring flowers and good food

Darren8306 replied to chuck123wapati's topic in All About Us and Off Topic

I ordered a cheap clicker die from Temu, and can now make use of some of my scrap. The die is CRAP lol. I knew that going in, but it isn't the problem I'm having. I'm not even SURE what problem I'm having. This thing looks like boiled ass, and I'm not even sure why. The stitching, often a favourite part, looks like I never learned how... Sometimes I have trouble seeing my work properly, until taking a break and looking the next day. Still looks bad. Can you fellows try to say why? At the moment there is not yet edge kote, or a finish on, by the way. -

Need recommendations for steel bar plate for work bench

bruce johnson replied to desullivan's topic in How Do I Do That?

Lots of rivets have been knocked out and set on this by the [previous owner and me. This particular one measures 5x3x1. I have had 5x3s and 6x4s fairly often in old sets. I have had two I can think of with the USA mark. That mark is US Army and listed as standard equipment in some leather repair kits (The "battery wagon box"). -

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

Beautiful, I looked into these too, but a grand is a little steep for me. heres a pair for 250 at Thursday boot company -

spring flowers and good food

AlZilla replied to chuck123wapati's topic in All About Us and Off Topic

I've been eyeing up various wing tip work boots from Shoebank.com (which won't load for me at the moment), which is the outlet site for Allen Edmonds shoes. At best they'd be a couple hundred bucks and up to several hundred. But, it's an itch that I'll scratch one day. -

Need recommendations for steel bar plate for work bench

desullivan replied to desullivan's topic in How Do I Do That?

I would be using it for copper rivets and other rivets. Belts and straps and saddle rigging. It just seems easier to rivet on my bench rather than balancing longer pieces on anvil while having hands full of tools. Aluminum will not work. Agree bounce needs to be avoided so the recommendations on metal 5hickness very helpful. The plate will be 5 or 6 inches wide and straddle the edges of two benches (i have gap due to 4" steel vertical beam on the wall the benches are on) and those benches have solid 4×4 inch wood posts. I plan to mount screw the plate to the benches. Stainless is pricy, may go with a cold finished flat steel bar and keep it clear of corrosion unless someone has recommendations to keep the steel as corrosion free as possible? -

That’s a great idea. What LEDs did u use?

-

While servicing my Juki, I noticed the underside of the body is flat and free of any oil holes or other objects. As an experiment, I installed a 6 inch self adhesive strip of LEDs and a 12 volt wall wart. The difference in visibility is amazing.

-

That is very true there are situations where you just can't get the bobbin thread. Nice tip for machines without reverse. kgg

-

spring flowers and good food

Handstitched replied to chuck123wapati's topic in All About Us and Off Topic

@Mablung former, akubra, newbie, again, statesman. My very first hat was a statesman and is now a museum piece on display in my workshop. My next pair of work boots will from an Aussie company, also not owned by a mining squillionare HS -

That is correct. It is a walking foot machine and is not a candidate for a roller foot conversion. If you really want a roller foot machine that is on par with you Outlaw stitcher, search for a Singer 45k with a roller foot installed at the factory. Or, buy a modern day clone like the Cowboy cb2500, which can be fitted with a roller foot by the dealer.

-

Some of us, myself included, have machines without reverse. We can either sew all the way around an object and overlap the starting thread about 5 stitches, or tie off the starting threads under the work, or spin the work 180 degrees and perform poor man's reverse to sew over the starting few stitches. As for holding back both starting threads, some jobs render that impossible. A good example is sewing patches onto vests and jackets where you can only handle the top thread. In this case I hold down the top thread behind the presser foot so it doesn't get pulled down into the shuttle during the initial couple of stitches.

-

Thanks for a great deal on these. Make me a deal on that class 20!

-

J Kellar joined the community

-

If the header didn’t give it away, I’m back to my first rodeo… I haven’t worked with fur before. Are there any tips or tricks for working with a rabbit pelt? I’m making Dieselpunk’s elf hat, and I intend to use the pelt for the trim, so nothing beyond basic. I’m just unsure of new materials these days… Thanks, and may you never burn your bacon! — AZR

-

How to prevent overglue?

ThisIsMyFirstRodeo replied to ThisIsMyFirstRodeo's topic in How Do I Do That?

Guess I should add in that regardless of what kind of adhesive, I stitch everything… -

cowkiller1873 joined the community

- Yesterday

-

How to prevent overglue?

ThisIsMyFirstRodeo replied to ThisIsMyFirstRodeo's topic in How Do I Do That?

So I didn’t get the lid closed enough on my cement (weldwood) and while attempting to thin it out with some acetone yesterday, it almost seemed to seize up on me. (Today, it actually looks quite usable though… 😉) Although I was working a different project yesterday (on a timeline), I still had to glue/cement/adhere a few pieces. But, because of the issues with the cement, I wound up using Gorilla wood glue. Seems like it did the trick in a pinch, even if less than ideal. Hopefully I’ll clear my production board so I can move back to my belt and keep going… Thanks guys, AZR -

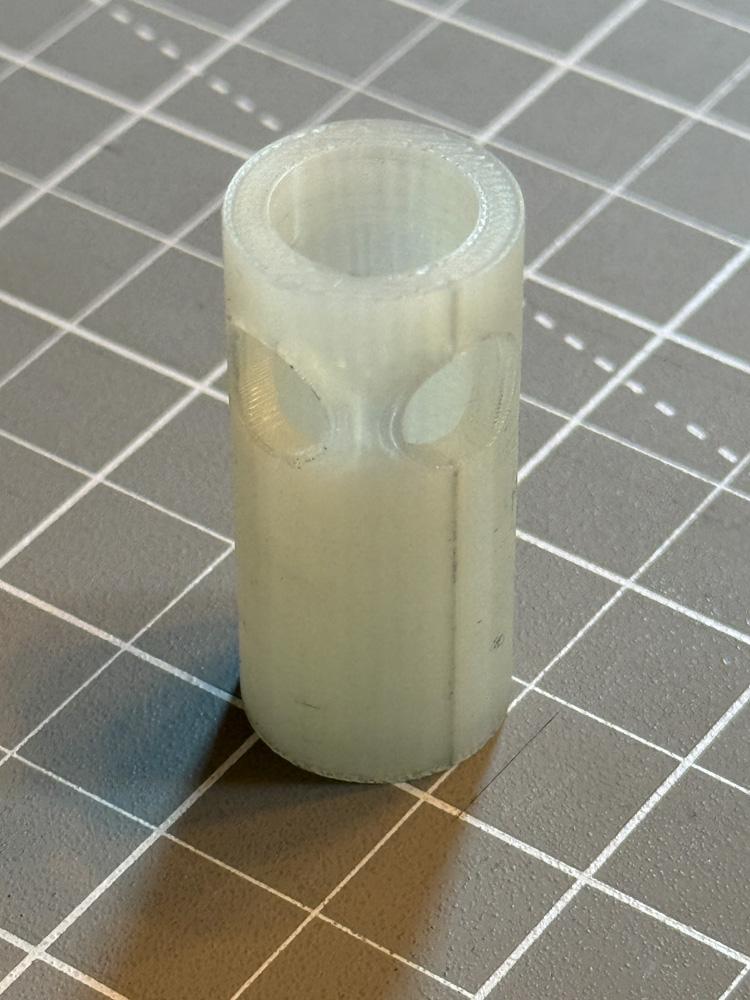

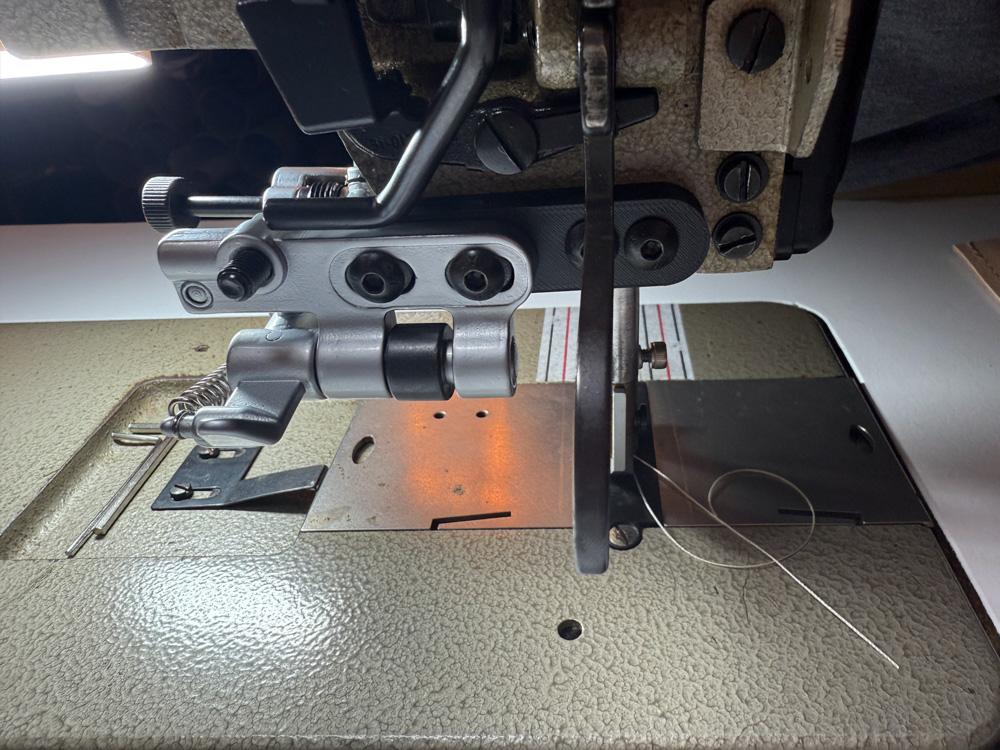

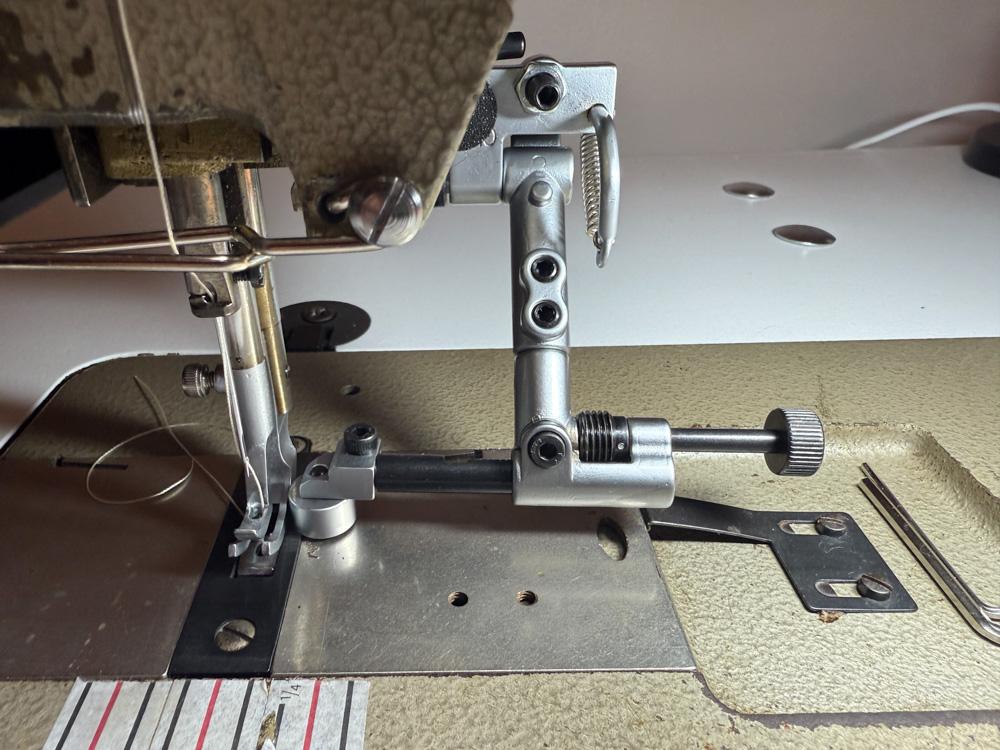

New to the forum. A few basic 3D prints for my Pfaff machines. Basic PLA used. Collar to fit a 3/4" bore 8" cast iron pulley as a larger hand wheel on a Pfaff 195. Pfaff shaft is 0.501", just a little big for a half inch bore pulley so adapted a larger bore to fit with longer set screws. With a brushed servo motor mounted 1-3/4" pulley, I can get as slow as about 20 stitches per minute. Also, bought a generic roller guide which doesn't fit all machines directly. Printed an adapter with brass heat inserts for my Pfaff 1245. I was very happy with how easy this was. Still learning best hole sizing for the inserts. Pfaff 1245 uses M5 threads, used the same for the inserts.