-

Content Count

358 -

Joined

-

Last visited

Posts posted by Timbo

-

-

4 hours ago, Rodeoman said:Can I get a #1?

I don't have any more chucks to make more. But #'s 7,9 or 10 would be a close shape to #1.

If I had any chucks left I'd be glad to make you one but I've got them all epoxied in.Let me know if you think any of those will work for you.ThanksTim -

3 hours ago, arashikage said:@Timbo I would be interested in the awl hafts 1 and 3.

They are in the mail and on the way!!!

-

26 minutes ago, bland said:What do you have left?

Awl hafts 5 through 10 are still available. They are all white oak. And all of the scratch awls are available. Let me know which ones you are are interested in!!

28 minutes ago, Tugadude said:Timbo, I'm glad that your awl hafts are selling now. Personally, I like the "repurposed" look of the scratch awls, but everybody's taste is different obviously.

For me, awls are tough to buy without a "test drive". What feels good to some doesn't to others. As you know, there are a lot of variations in awl hafts and there are even "ergonomic" shapes that supposedly fit the hand better.

Your awls are certainly a great value at the current price. I'm sure that you don't want to have to discount them though. One thing you might consider is reducing the variety down to perhaps three models. Those models can vary a bit in size so that there is a choice for those with small hands and a choice or two for those with larger hands.

I'm only speaking for myself, but sometimes when I'm faced with too many choices I just move on.

Good luck in whatever route you choose.

Thanks for the advice!! It is appreciated!!

-

They are yours Tony!!! Thank you so much!!!

-

Thank you Rick!!!! Glad you like them!!

-

Number 2 and 4 are sold!!!

-

Thanks for the input guys. It is appreciated.

-

Would someone please give me some honest criticism as to why nobody is interested in these??

-

Not having any luck selling these, so I lowered the prices. Now you can get a handmade haft or awl for the price of a factory made Osborne...... and help out a fellow leather craftsman in the process!!!

I recently learned how to use a wood lathe, after all these years of wood working and having access to it, I finally started using it.

So I decided to make some awl hafts. The chucks are expoxied in and go about an inch and a half deep with the extension I put on them.

Each haft comes with 5 brass collets to fit anything you want to chuck into it. Some small enough to chuck a sewing needle into as well.

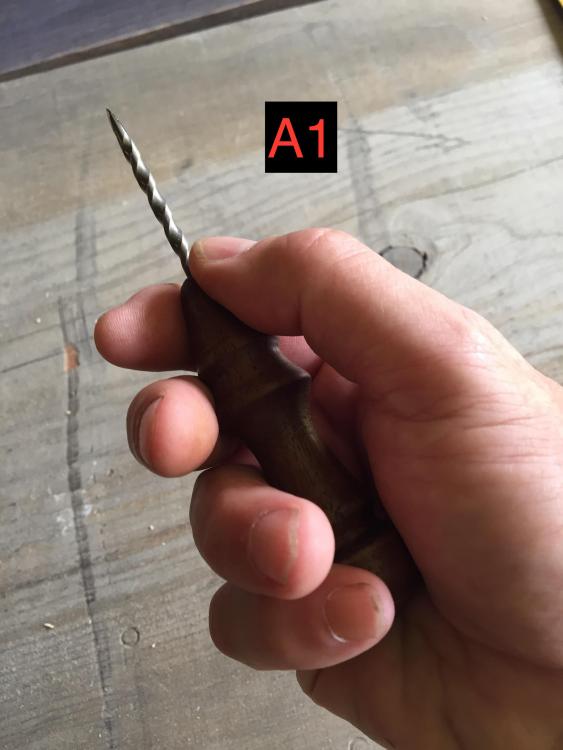

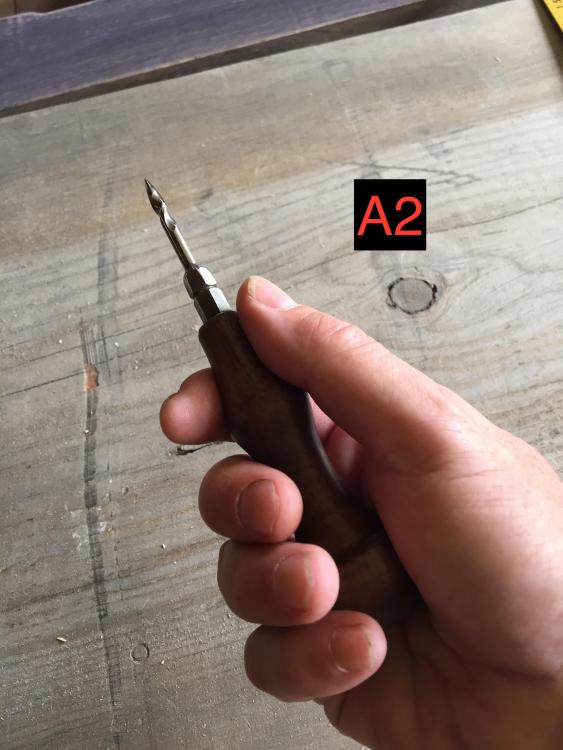

I am posting pics of them as well as some scratch awls I made from up cycled hammer drill and concrete drill bits.

All the hafts are white oak and some have been stained with vinegaroon to turn them gray, some are natural. All are finished with wax and buffed smooth. No poly.

The scratch awls are walnut handles.

The one black awl haft is what I think is Douglas fir from a 112 year old church. It is good stuff but light weight. The vinegaroon turned it coal black!! Which I think looks pretty cool. This is old tight grained wood. Close grain that you can't find anymore.

I am asking $20.00 each for the awl hafts and $15.00 each for the scratch awls.

I am currently in Missouri and that is where they will ship from. I have looked into shipping and it looks like shipping will be cheapest with USPS Priority Mail. If anyone has any better ideas please let me know. But it looks like shipping will be $7.50.

I will be taking payment through PayPal. If you would like to purchase one please respond to this posting with what number you want and also email me at: drunkhorsecustomleather@gmail.com

If you want more than one let me know that too and there will only be one shipping charge.

I have included a lot of pics including one of each in my hand so you get an idea of the size. If you would like more pics or information, please ask.

So with that here are the goods!!! Sort through the pics and see if there is something you like!!! And thanks for looking!

-

Sorry guys, haven't been around much in the last couple years. This tutorial has been up for quite awhile, and I appreciate all the comments and am glad you folks are getting some good pointers from it. As for stain and finish, I have a distain for "eco" anything. I use Feibings oil dye and for the canteens I just give them a coat or 2 of EVOO. Sometimes I'll use Bee Natural Rudys.

If anybody has any questions and want a quicker answer than a couple years, just email me at drunkhorsecustomleather@gmail.com

-

Good job!!!!! I like that a lot!!!!!!

-

Looks GREAT!!!! I love endurance type saddles as well as Aussie saddles. Love the rough out. So the big question.............How much does it weigh????

-

The wax also helps lock the stitch together inside the stitch hole.

-

Here's the best tutorial for it you will ever find!

-

Fiebings Atomic Balm with atom wax leaves a nice shine.....always was too shiny for me, but might be what you are looking for.

-

Who has the most level lightweight saddle skirting???? I am so tired of skirting that runs off from 12 to 8 oz. I'd be willing to pay more if it is all a nice uniform usable for my purpose hide.

So tell me what your experience is.

-

I have a delrin stamp and while it works ok, no matter how hard you whack it or whack it repeatedly it will not make as deep of an impression as the metal one. The delrin just does not have the depth that the metal stamps have. The other problem I have with the delrin is that it is round. No matter how well you mark it and work to get it centered and correctly oriented it is still a crap shoot. The square base of the metal stamp would be great as it is easy to get it correctly oriented and square. I don't know how many times I thought I had mine lined up correctly, whacked it, only to find it was turned just a little bit off.

So in summation.......I'm gonna order one of these Phillips stamps.

Tim

-

Hi Tim,

Thanks for the tutorial, especially for sharing the trick about positioning the letter-stamps. It works wonderful and helped me a lot.

Greetings from Germany (and excuse my bad english)

Lisa

Glad you like it and found a use for something in the post. (and your english is fine)

Tim

-

Nicely done...professional done for sure! Where do you find how to make the strap...I would like to make a similar one for my son...it would be a first for me.

Well, didn't really find anything on how to make it. Since it was for me it was easy. I play acoustic and electric so the acoustic setting is adjusted all the way up high and then the electric will be somewhere down lower.

As for design I just kind of made it up as I went along. I knew I wanted to use the diamonds but then figured out turning them on there side looked good too......and used a lot more of them as well. I didn't like the shiny chrome look of them so I scotch brited them then gun blued them then lightly scotched them again. Made them look old and used. And I knew I wanted it wider over the shoulder and back and thin where it attached to the guitar so I just figured out a little notchy holey thing to transition from one to the other. Oh and from one end to the other it is fully lined and handsewn with 5 cord irish linen.

Don't know if that helps any or not......but that's my process when i built it. you just have to have figure what your finished target measurement is going to be and go from there.

Tim

-

covering an amp in leather would be very cool!!! Funny but back about 1978 I bought a brand new Peavey amp that had been dropped off the back of the truck and broke the case......I got it for super cheap and my Dad and I made a new case for it out of rough sawn cedar.....made it look like a shipping crate. Several years later, guess what line of amps came out that looked just like it??? Yup Crate. And yeah I've bought the occasional guitar over the years to fix up. But I've always kept my first "real" guitar I got when I was 14........did some fast talking and talked my Mom into buying it for my Christmas present. It's a 1971 Les Paul Gold Top Custom.

My brother also builds custom electric guitars. Check him out at www.williamjeffreyjonesguitars.com

-

Man that looks awesome! But the guitarist in me cringes at all that metal that can bang up and scratch your new baby.

What brand of guitar is that? I have never heard of Great Divide before...how does she sound?

Yeah you just gotta be careful with the studs and buckles but its not that big a deal with this guitar. Great Divide is/was Bedell guitars low line. They discontinued the line this summer when they bought Breedlove guitars. I bought this at there Aspen store. (2 Old Hippies) Got it for a hundred bucks and the main purpose of it is to take camping.........so if something bad or stupid happens to it, it won't be that big of a loss. But it is an awfully nice guitar, especially for a hundred bucks. Abusing a guitar is something I just can't do though. So I bought a nice used Guild case for it off of craigslist. Oh and it plays and sounds great........better than some more expensive guitars I've had in the past.

Tim

-

-

Looks good!!! What part of SWMO??? I'm from Neosho originally.

Tim

-

Handmade awl hafts / NEW LOWERED PRICES!!!!

in Old/Sold

Posted · Report reply

I can but it takes awhile and I have to buy in quantity. Let me see what else I can come up with.