DONAG

-

Content Count

26 -

Joined

-

Last visited

Posts posted by DONAG

-

-

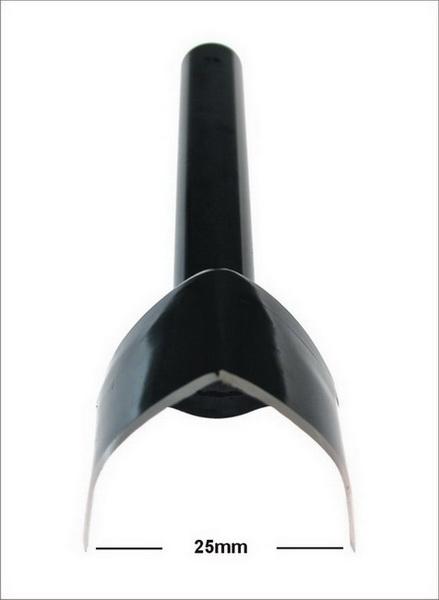

I make watch straps and straps tend to be in MM's Thing is. Nobody makes V punches in mm's. Found one seller, but designed to align in imperial widths

Surprising that the majority of the world works in metric. Some tools still made in imperial.

As to widths. If I bought a 7/8" The widest opening is not 7/8", but 15/16" and this size is under 24 mm, so I have to move to the next size up which is 1" (1 1/16") or 3 mm wider than 24 mm (works for 26 mm wide straps).

This leaves a slightly stunted tip rather than a little more elongated one

No plan on replacing the punches I have. Just curious

Thanks

DON

-

11 hours ago, RoycesLeather said:If you don't mind spending some money you should check out leather wranglers I believe he is making splitter blades now for both Osborne and Tandy models. You will have to wait to get it but it would be a replacement for you. I have not used his splitter blades but if they are anything like his round knives they are super sharp and a breeze to use and maintain.

Thanks for the info, but if he's making for the Osborne model. Most likely it's the Pro blade as both are similar (wider and longer) than the base model with smaller blade which is what I have.

I was lucky enough that Tandy had springs for the model. Never asked about the blade, but I'm sure it's over $100US and cheaper to just have it reground

Thanks

DON

-

So my blade is still not up to it's optimum level. Need to pick up some more emery paper to get rid of the secondary bevel or flatten the bottom. Not sure what is causing the actual problem.

Odd thing is. I watch 3 videos on sharpening the blade and two people put a secondary bevel on the blade. One with a stone. Second using a flat piece of honing steel

Can't figure why it's not cutting like it used to. The leather (depending on temper) will ride under the blade pressing the roller down and blade refuses to bite into the leather at a certain point

I used to be able to cut down to 1/2 mm, but can only do that now if I piggyback the leather on top of another piece and still iffy that the cut is even. Might try a 1/4" piece of wood under the leather.

Can't even buy replacement blades for this model

I either flatten the face myself or pay the company the fixed it up last time another $100

Thanks

DON

-

11 hours ago, mike02130 said:Micro edge on a plane iron or chisel serves a different purpose. Other than making it easier to sharpen, it also assists in the wood shaving moving away from the edge and creating less drag. I question how important that is but there are plenty of sharpening nuts out there. A machine jointer or planer blade never has a micro bevel.

I would think whatever the factory grind is or was would be correct. You must have plenty of blade left to check it out with a bevel gauge. With such a wide bevel and a 6" or 8" blade it'll take quite a bit of work to flatten it out to get rid of your micro bevel. I'd be tempted to send it out to be ground and then maintain it's angle.

I had the blade ground last year as it was not flat and main face has a 30 degree bevel. Still flat and I do occasionally do the face with my water stones with 1000/4000 grit.

I usually spend about an hour doing the face of the blade to make sure

Thanks

DON

-

I used to put a micro edge on my splitter blade (Tandy splitter), but found it hard to pull the leather though.

I thought like my woodworking blades. I was taught to hone the main face and then apply a fine micro edge at the tip. Works fine for that, but not so much for leather.

I made a strop from a hard piece of leather and glued it to a wood board and tried a micro angle that way and still not great. Decided to try heavier angles and found about 60 degrees creates a better cutting edge.

Odd that this angle didn't work for a soft leather I have, but sliced through pretty much everything else

Curious what angles others sharpen at?

Thanks

DON

-

My 7/8" and 1" are Osborne. I have a 3/4" from Jeremiah Watt which is close to perfect width wise as it's a shade over 20 mm

Vergez Blanchard sells in MM's, but again. Length or is it width? Unfortunately. They charge a lot extra with each size increase, so way out of my price range anyways

Thanks

DON

-

Many years ago. I bought a 1" punch from Tandy and a 1 3/16"" punch arrived. Thought someone made an error, so ordered a second and got the same width.

Bought a 1" from another company and was told by seller. If company says 1". It's 1". Well it's 1 1/16"

7/8" from same company is of course 15/16"

The measurement given is actually from the tip to the back end and maybe I'm missing something, but who cares about that?

If you advertise 1". Why is it not 1" wide?

I work in MM widths, so those added inch fractions end up slightly wider than the MM size I do need, but have no choice but to use them

Maybe someone could explain why the front to back measurement?

Thanks

DON

-

Posting on the ending of this topic.

Bought 4 springs which cost a couple of dollars. $13.00 by UPS to ship to Florida where they sat until today

I screwed a hook into a piece of wood, placed a second as a brace and used a double coil of stitching thread to pull the new springs out and all is good.

Tool back to working order

DON

-

Hi Brian,

40 mile round trip. I figure you need a stretching tool which hooks the spring and pulls it out.

I can probably make something up or look around in my mess of parts. Just didn't think the spring would be that tough or break that easily

Thanks

DON

-

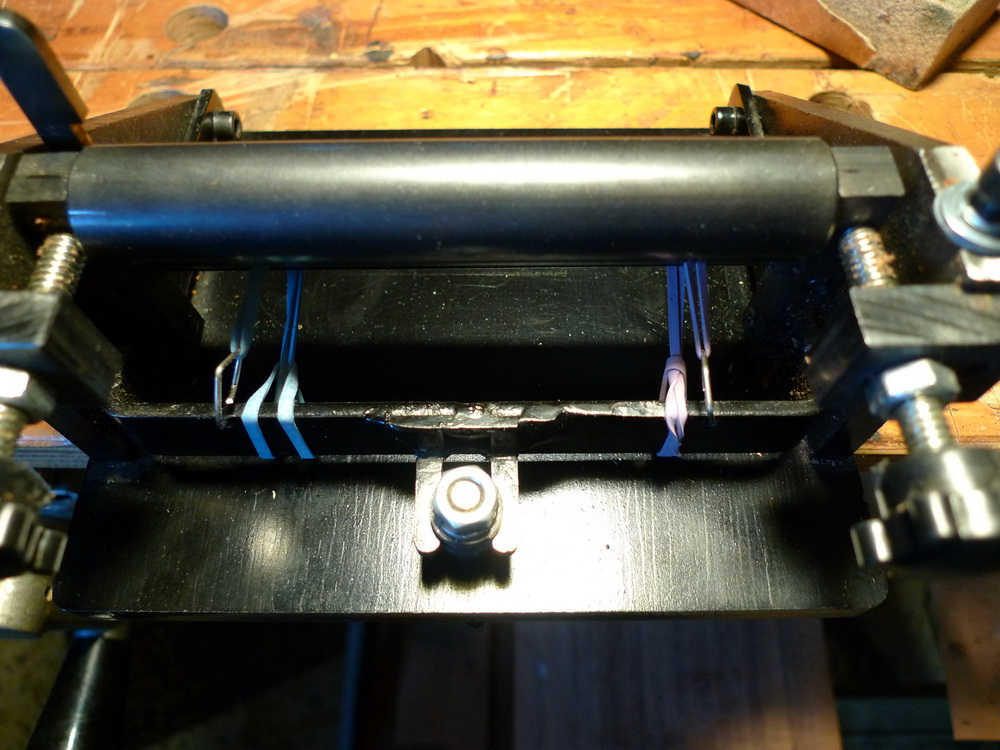

Splitter Part 2

I assumed Tandy would not have spring s (don't have spare blades), so I removed the second spring to measure dimensions.

Based on the design (round end one side and square the second). Nobody would carry this, so tried to place it back on the tool.

Very difficult. Spring steel and tried to stretch it out with needle nose pliers and on the third attempt. Broke the second spring

Called Tandy and manager did a check with the head office and they have extras, so asked for 4 of them. Will have to come up with a new method to stretch the spring out with less stress on the end.

For now. Makeshift repair with short rubber bands and bent metal clips from a thick paperclip

DON

-

Thanks Tom,

Closest store is a bit of a distance from me, but site didnt have the size needed

they did give me the name of the type of spring, so can search for them elsewhere

thanks

DON

-

Working on some leather when I hear a ping and turns out one of the springs for the roller pressure plate snapped. Still have one spring and I suppose it will work as well as two

Has anyone found parts for this tool?

I emailed Tandy when my blade had a warp and they said they didn't carry spare blades (odd for a $300 retail tool not to have spares), so I'm guessing that they won't have springs either

Tried bending, but not enough on the end to work

Here's the image and you can see the spring. What can be done to replace if not available?

Thanks

DON

-

I just checked and the 151 is an elongated hole punch

I'm looking for an English Point tip punch listed as 150 on a site

Thanks

DON

-

Years ago I bought a 1" Tandy punch. Turns out it was 1 3/16ths" wide at the opening. Thought someone made an error and ordered another which was the same size.

Seems it's measured from the tip to the back edge which seems kind of stupid

Been using it for 26, 24 and 22 mm, but angle gets worse by the time I use for 24 and 22 mm

I figure an opening of 25 mm or 1" should be OK for the 2 smaller widths

If anyone can measure one of theirs. I'd appreciate it.

Thanks

DON

-

I have a Tandy splitter, but don't pull anything wider than 28 mm through it. Too much of a struggle. I wrap a folded piece of leather at the end and clamp it with a vice grip to pull leather through.

I hone the blade on my water stone and then strop a sharper edge on the tip. I've thinned leather down to .5 mm with it.

Leather has a grain (sort of) like wood. It might stretch one way, but not the other. I pull along the edge to see if it stretches. If it doesn't. I cut the leather that way. If it does. I cut across. This prevents leather from stretching out which I try to avoid on leathers with patterns or it pulls the pattern out of the surface.

Leathers that are too soft will stretch regardless of direction pulled when they reach a certain manual splitting thickness, so best to have the leather split if ordering from a tannery

DON

-

Thanks Bill.

As mentioned though. I do various widths and tapers, so can't use screw or glue down frames to hold the leather in place.

Good idea though for belt makers

Punch is sharp. I hone it on water stones and then green honing compound to finish the edge

Thanks for the other suggestions

DON

-

41 minutes ago, Squilchuck said:Tandy sells nice templates with a half dozen strap sizes in one - round and tapered. I use them too with a knife. --John

Saw that, but in Canada it's $36.00 with a jacked up exchange rate, tax and s/h

I'm stuck between stores which are at opposite ends of two district city limits, so getting out there is a chore

Will just keep practising, but will check Ebay on the template

DON

Bought a template off Amazon just to have and included free s/h. Same price as Canadian store price with exchange rate. Just don't have to drive out to get it or pay for s/h

-

Thanks guys. Will try different things.

Die doesn't help as I'm working with different widths and tapers

Can't do a light stroke tap. If not right. it's on the face of the strap and customer will see it

Will do tests tomorrow and see what works best

DON

-

Funny thing is. When I do tests cuts. Works fine. When I do the actual strap. 50/50. Like it has a mind of it's own and knows

I have Rhino board on my downstairs desk, but will check a cheap cutting board to see if it has lines on it. Rhino board doesn't have them

Thanks

DON

-

I place my English tip punch at the end of my strap. Check both side to see the amount of overhang and rarely get a good cut

I have the center marked, so I know the tip is in the middle

Angle is 50% of the time off which means I have to re-cut the tip. Little heavier to the left or right

I'm using a 1" punch for 22, 24 and 26 mm. I have a 3/4" for 18 and 20 mm

A section that was supposed to be 125 mm is now 120 as I had to cut it 3 times to get it close to even

Thanks

DON

-

On 9/13/2018 at 2:45 PM, chrisash said:OK I will bite , What is so special to charge that much for so little, I have never heard of it, so please sell it to me with your wise words

Sorry for the late reply, but as Sceaden mentioned. Leather is restored from the Metta Catharina which was a fluke find as the divers were searching for another ship.

Leather is known for the dicing pattern and the aroma of the oils used in the restoration

While there are still some leathers down in the hull. It's considered too dangerous to get them

Leather has been sold

Thanks

DON

-

Selling off the last of my Metta Catharina hide which is about 2.75 sq. ft. Back in 2009 I was selling 4 x 6 inch off cut sections for $45.00 with no dicing pattern in the material

This piece has very little dicing left, but still has the history, color and aroma. Enough material for straps, wallets small notebook covers etc.

Been using it to make smaller dress styled straps

Material is thinner at the bottom at about 1.5 mm and about 2 mm further up. Best if you have access to a splitter for thinning out. Preferably an electric or hand crank.

The hide is 9 years old. Friend suggested a conditioner for the leather even though it’s been kept wrapped up in plastic when not needed. Could still use a refresher

Leatherique leather conditioner which is available pretty much in any country although you may have your own to use

Large image to view the hide up close –

Cutting up creates the best strength as your cutting against the grain

Price for the hide is $650.00 firm

S/H with insurance and tracking is either

$44.00 to the US

$80.00 International

Shipped from Toronto Canada

New here, but been around the internet on various watch forums for 20 years

If interested.

Please email me at tickman@rogers.com

Thanks

DON

-

I tried waxed thread and never liked it. Found some actually grabbed dye color from the leather.

I tried the double loop lock and it worked fine. Thread made it all the way without shredding or bunching up

Trying to figure out another problem, but working on it and see if I can correct it

Thanks

DON

-

Thanks guys,

I peel off a few feet of thread. Leave a couple of inches, pierce and slide over the needle to create a locking loop

Problem as mentioned is the 3 strand thread which begins to unravel as you turn and pull the needle thread through. It's sewing machine thread, but still thick enough at .33 mm

I forgot to mention I use nylon thread as I can heat seal the finished ends when done

No problem with the big needles. It's the tiny ones

Thanks again

DON

V tip punches - why Imperial?

in Leather Tools

Posted · Edited by DONAG · Report reply

I have 2 from China. A half round 20 mm, but the other 20 mm is more of a slanted cut with round tip rather than elongated design

Since most of mine are Osborne punches. Doesn't pay to run out and buy replacements

Thanks

DON