-

Content Count

57 -

Joined

-

Last visited

Posts posted by HardenGoods

-

-

33 minutes ago, Trox said:Hi, Yes s Uwe yours have just groves that makes it harder to get tight tension on thin threads. His is worn right true and would cause problems, I would have changed that bobbin house for a new one...You can get them aftermarket for a good price.. You could try to widen/make the hole round again with a small diamond round file or simmilar..But remember it has to be polished afterwards...Use a white ceramic thin stone....

At this point I will try anything to fix my tensions issues. Feels like I am down to the point where it's a parts problem. Perhaps I will try widening the hole very carefully and then polish off with a high grit stone as you suggest and if it doesn't work lean towards a new bobbin top case.. maybe throw in a new check spring too as they are cheap. Thanks for the link, that is a reasonable price!

-

10 minutes ago, Uwe said:There you have it - more than you ever wanted to know about that obscure detail.

Haha, no I'm happy to gain all the correct knowledge I can on sewing machines and you seem to have a lot of it Uwe! That would explain my lack of results when researching "bobbin lifter" too. Very happy to know the purpose of it now as it was the only adjustment out of all of the adjustments covered in the english translation of the 167 service manual that I could not wrap my head around.

And you are right, the bobbin top case is expensive.. and most of the parts, for that matter. I'm trying to get my hands on just the thumb tab that releases the bobbin top case right now and was quoted at $110 Canadian plus shipping and tax. Mind you, the tab isn't sold as is (comes with spring, retaining pin, lower case), but still!

-

2 hours ago, Trox said:Yes these are important factors, you will get a more consistent top tension threading true several holes. You probably got to ease of on the thread brake, thought. When you the thread knot laying on the top and it suddenly happens in the middle of the seam, those are factors I would have looked out for. Could be caused by uneven bobbin winding or bobbin case opener too, but then perhaps more frequently and probrably with the knot on the bottom. However, everything must be correct...check all thread paths for chips in the metal etc. Good luck!

Yea, I am going to cover all bases for sure. In some ways this is good because it's forcing me to learn every square inch of my machine.

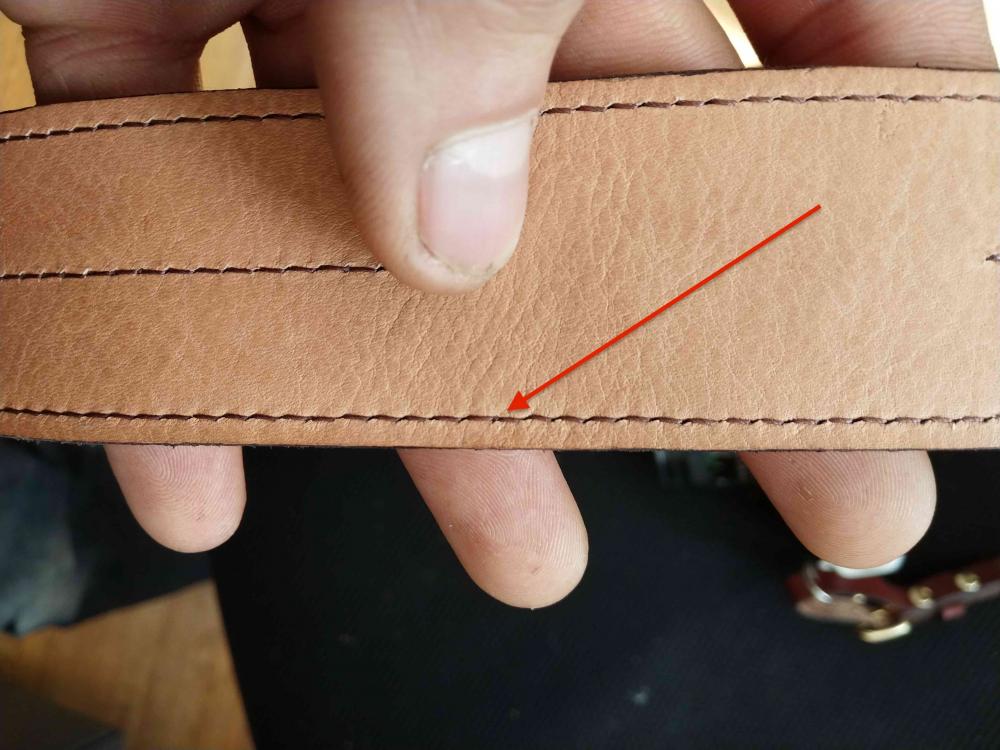

In regards to the bobbin case opener (now that I know its' correct name), am I just adjusting the set screw to allow the width of thread I am using to pass through and no more and no less? Also, do you think this groove in the bobbin top case could be causing it? Not sure of the groove was placed there by manufacturer or if thread has rubbed its way in over the decades.

Thanks Trox!

-

2 hours ago, Constabulary said:Guess you mean the bobbin case opener - that would have been my suggestion. I´m sure UWE has a YT Video how to adjust it.

I would probbaly try to increase both top and bottom tension a bit and I´d also play with the tension of the thread regulator spring (check spring). Just a guess w/o sitting in front of your machine.

I will double check the thread regulator spring (check spring). I watched UWE's check spring video a couple of weeks ago and adjusted it then but it didn't seem to change much. I think I'm going to try adjusting the bobbin case lifter (thats what the manual calls it) and see if it helps. Thanks for the feedback Constabulary, I really appreciate it.

2 hours ago, Trox said:When something like this happens it' often because the top thread suddenly get a brake or bottom bobbin is uneven winded. To make the top thread tension stabil you need to make sure of the following factors.... On the thread rack...(use left twisted thread, it usual left twisted) the thread guide on top of the spool must be placed exactly over the center of the thread spool/cone... If it off center you will have uneven top thread tension. Make sure you thread it true at least two holes in the top pin post guide....you can even apply more tension by use several holes....this way you will have a stabil top tension....Bobbins must also be evenly winded... good luck!

Trox, that is one thing I have not tried (using several holes in the top thread pin). Will also look into the thread guide in relation to spool. Thanks a lot for the input!

-

Hi everyone, I was hoping to gain some knowledge from some of the Adler experts out there. I’ve got an Adler 067 GK-373 and I’m having trouble with the thread tension.

The trouble is not that my knots come up through the top all the time or the bottom all the time, but rather, even after dialling in the correct tension on a scrap piece from the same leather/project I am about to sew, I still get intermittent knots on the top and on the bottom (in the same run). They only show up every few inches and it seems to be worse when I am graduating from one thickness of leather to another (eg. wallet pocket layers), but they show up on straight stitching single thickness pieces too.

I’ve scoured these (super helpful) forums and internet at large but nothing has worked. Things I’ve tried:

- changing thread

- following the thread path through the machine to make sure machine is threaded properly

- watched the machine as it was sewing to make sure there are no snags anywhere

- ensured that the thread cone is letting the thread off without snags

- changing feet

- holding thread back at beginning of stitch run

- making sure I’m not accidentally touching knee lift at the wrong time

- brand new bobbins

- ensuring that bobbins are wound properly (as per manual and not to one side)

- increasing bobbin tension and decreasing top tension

- decreasing bobbin tension and increasing top tension

- changing needle (in relation to thread size both up and down)

- machine timing (as per Use Grosse super helpful videos on youtube)

- I have throughly read the english translation of the mechanics guide for the machine and configured it exactly as the manual has suggested (eg. check all screw seats, needle entry, hook adjustment, needle guard, needle bar height, presser bar timing and height, feed dog timing and height, needle feed, top feed, foot lift height, check spring etc).

- not lifting presser foot any higher than needed to release the fabric on turns

- proper oil and consistent oilingThe only thing I feel I have not tried is adjusting the bobbin case lifter but it doesn’t seem to be off as per the manual suggests.

Below are two photos of the same piece/same run with problems on both the top and the bottom. I’m going nuts over this and it is slowing down my small batches tremendously. Any help would be sooo very much appreciated!

-

Thank you so much Uwe! Had a hard time tracking down documentation on this.

Adler 167 - Timing Belt Replacement

in Leather Sewing Machines

Posted · Report reply

I know this is an old thread but wanted to say thanks because this was super helpful.