unionattic

-

Content Count

24 -

Joined

-

Last visited

Posts posted by unionattic

-

-

So on further investigation, I think why i'm seeing the weird stitching on the piping is that it's first folded and sewn together with one stitch, and then that folded-piping assembly is stitched into the binding-tape/canvas sandwich.

However, the bottom of the folded-in-half stitch itself looks weird with a bunch of extra loops.

-

I'm tearing down an old Louis Vuitton 'Saumur' bag from 1994. I was beginning to remove the piping and I notice that the stitch holding the piping to the canvas is unusual. One side (wrong side of the canvas) looks like a conventional straight machine stitch. But on the canvas side, the stitch is odd -- there is some kind of looping going on where there are two segments of thread linking each set of holes. I haven't noticed such a stitch on any of the binding tapes or the handles/straps of the bag.

Wondering what/why this stitch is? More of a curiosity -- when I put the bag back together it'll have to be a conventional machine stitch.

-

Was trying diagnose a stitching problem on my Pfaff 471. Checked the bobbin case and realized that one of the two screws that hold the tensioning finger has fallen out. Vainly looked around for it, but it seems to be gone. No idea what kind of pitch/size this would be. Any ideas where to look for a substitute?

Also, looking online see lots of (I assume) Chinese-made 10159 case replacements. My inclination is to avoid these and stick with this sixty or seventy-year old original.

-

I worked out the issue. Operator error. The machine was fine. In short, when I place the needle, there was slack top thread, so it would get sucked down into the bobbin-side of the workpiece. I made a dull video to demonstrate what was happening.

Avoiding tangled thread on start of a stitch

-

On 2/4/2021 at 2:06 PM, Pintodeluxe said:Timing slightly off and worn tension discs are likely culprits.

what tension discs? The discs under the white button tensioning the top thread? It seems to be a bobbin thread phenomenon, not top thread.

-

Does anyone have any hypotheses on what's causing this? It's really annoying and messing up some shoe-work I'm trying.

-

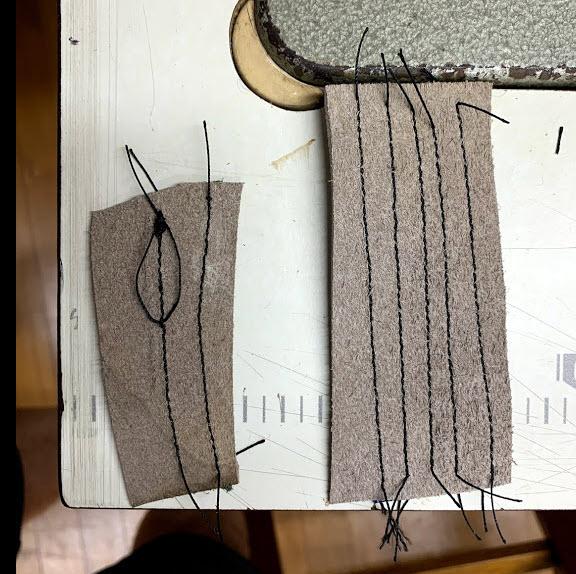

I have a sixty year-old Pfaff 471 postbed machine. I'm using Serafil 20 and Serafil 30 thread mostly. Am sewing ~1.0-1.5mm leather. I'm using a powerful servo motor with needle positioner which makes using the machine very nice. I've got one problem I'm unable to debug, however, Intermittently when I start a fresh stitching row (generally sewing leather) the machine stumbles for a few stitches and then starts sewing totally normally. However, on the underside, a tremendous amount of bobbin thread (I presume it's the bobbin thread) is tangled up. The remainder of the stitch, top and bottom, is beautiful.

I cannot figure out why this is happening. It doesn't always happen, although it happens in spurts. Pulling on the top thread and bobbin thread when I start the stitch makes no difference. It occurs regardless of whether the bobbin is full of thread or nearing empty. I'm not messing w/ stitch length or tension or sewing speed, so those variables aren't contributing. It's really annoying because it's intermittent and ugly when it happens.

Attaching a couple test pieces I used when I was trying to diagnose. As you'll see, I only got the starting tangle once in several tries. Sometimes it will happen far more frequently.

-

Constabulary you sorted everything out for me, thanks. I didn't realize that I could pull the thread up and over the prong in the disk.

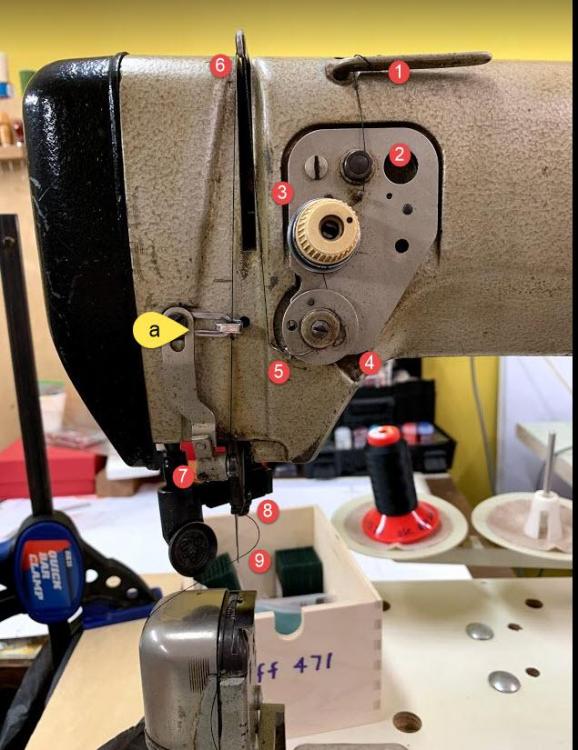

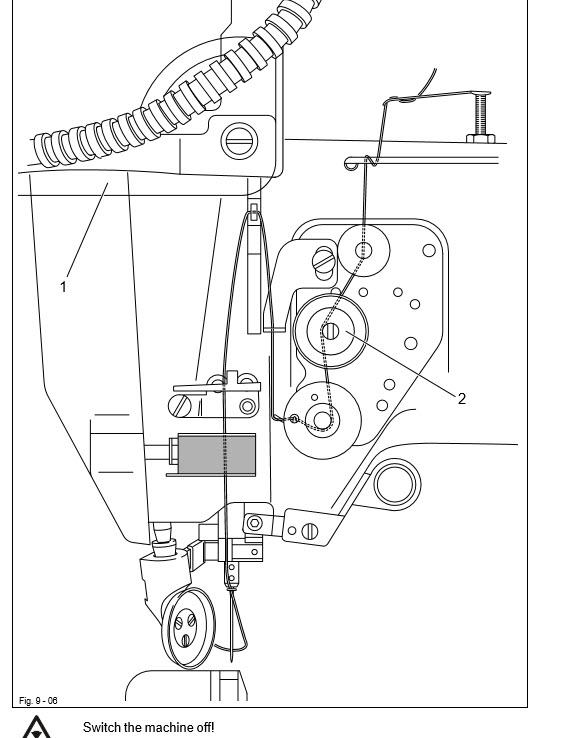

Album of what I think is properly-threaded + detail of the spring tension plate.

(sadly youtube seems to be ignoring the "slow motion" of the iphone movie -- it's running at full speed)

-

Bumping hoping someone has a suggestion for this thread-path quandry.

-

I investigated the spring and disk around #5 to see what adjustments or freedoms were available. I took off a locknut, removed the disk, and discovered that the pin which prevents the disk from rotating appears to be either a repair-job or a homemade addition. Nothing else on this german? swiss? machine is so crude. It's a tiny roughly-sawn rod that is silver-soldered into the machine. I don't see anyway to adjust the location or tension of the spring with this setup.

-

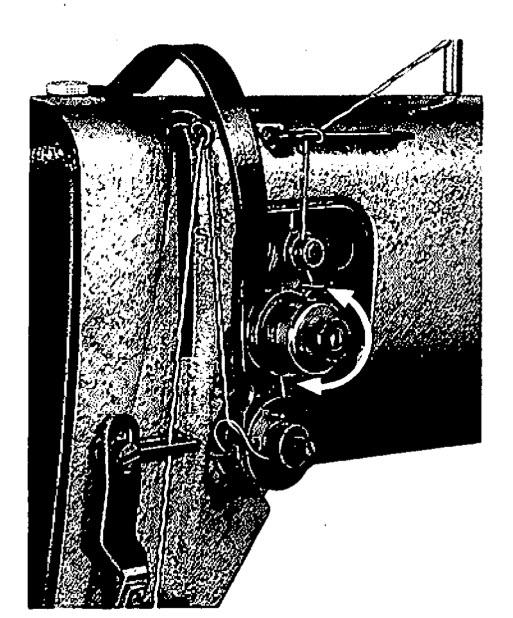

First thing I've tried is to re-thread the machine according to the advice above.

But the problem is that once the machine runs, the thread flips off the spring at #5, and quickly the entire system loses all tension and the stitching is ruined.

The spring at #5 has a hard stop that stops it from rotating counter-clockwise any further, so it doesn't put much tension on the thread. Also the shape the spring is rounded along the edge, and it basically flat across, so it's easy for the thread to slide off to one side or another of the spring. I will attach a close-up picture of the #5 assembly.

I have an ancient, hard to read manual for my (1950-era pfaff) and a modern manual for a modern version of 471. Both seem to show that spring at #5 being substantially more loaded when threaded than mine is. May the spring is somehow adjust to be too forceful? Or the thread is still somehow not following the proper path? But indeed, neither manual diagram shows the thread passing through #A twice like I did in my original posted picture.

-

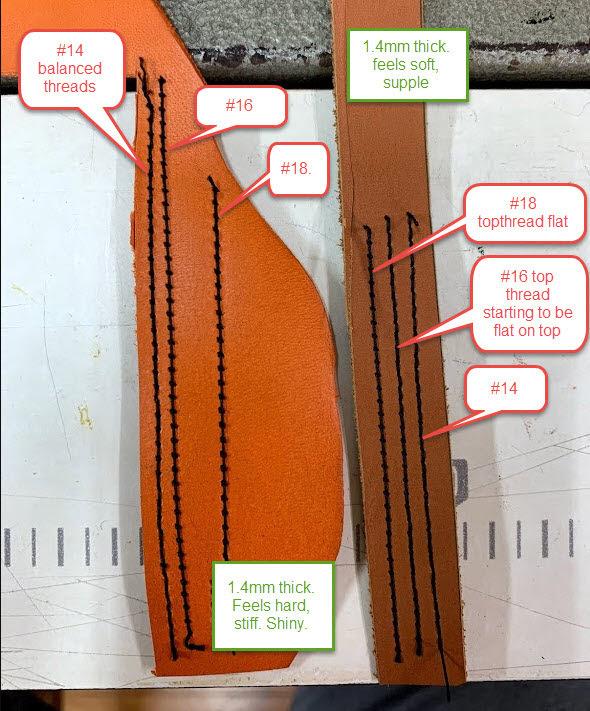

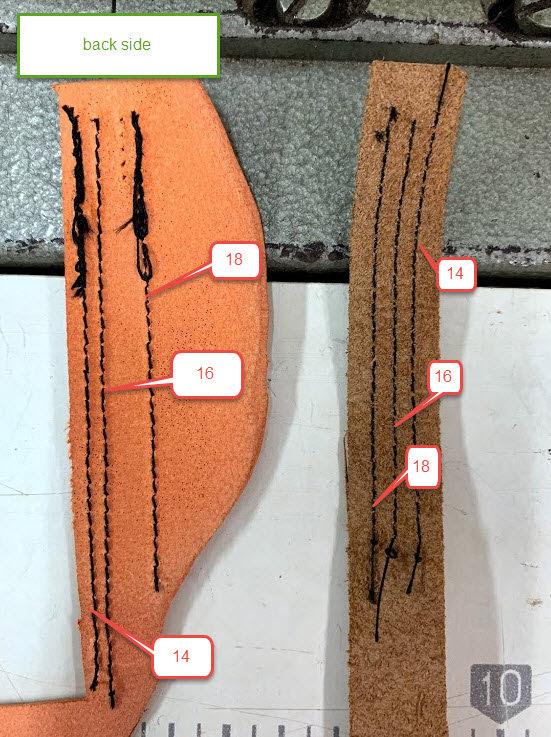

My Pfaff 471 was operating ok with my leather once I used a heavier needle (#18). This weekend I worked with a new hide of leather. It's same thickness (~1.4mm) but is significantly stiffer, harder, shinier than the stuff I first used. Both are veg tan leather.

What I discovered was that setting that worked well on the original leather worked terribly on the new leather. The main complaint is the top thread lies on top of the leather, flat, and the bobbin thread comes up and loops over, very proud. I also realized that needle size affects this -- the larger the needle, the worse the top-thread-flat effect is.

I''m using size #30 Serafil thread.

I suppose that I may have mis-threaded the machine. Two things that bother me is whether Point #5 is correct, as the thread never presses against that light wire spring very much. Also the small tension wheel #7 doesn't always seem to stay tight into the discs.

So it's like there are multiple independent variables to adjust here. Potentially top thread tension and needle size. Further confounding the problem is that this was just a test on a single ply of leather. Ultimately I will sew several skived layers of this leather for a wallet, so even thicker. How should I approach tuning my machine?

I've posted an album with an example topstich of both leathers in three needle sizes.

-

15 hours ago, Gregg From Keystone Sewing said:I made a short video, hope this helps. No other way to describe it. YouTube of bonded and non bonded thread example

Perfect! (and a great soundtrack)

-

Hey guys... Today I tested out a #18 134 LLCR on the same trouble 4-ply leather (and I rotated teh needleso that the scallop faces the hook of the machine). And it sewed well. I have uploaded a video of the successful stitching to the same album above.

-

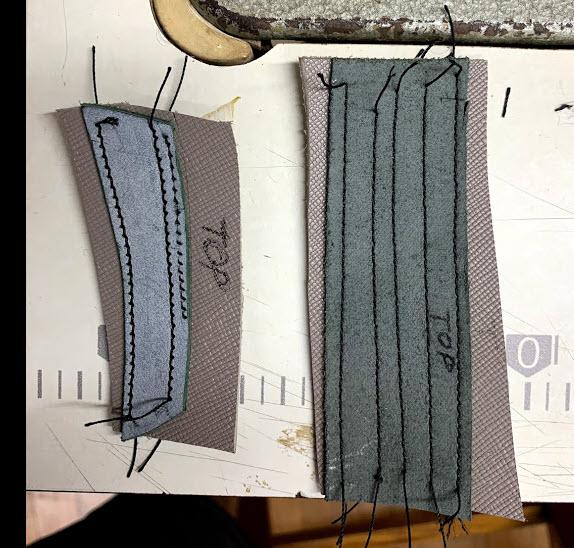

23 hours ago, unionattic said:Experimenting with my Pfaff 471. I can dependably(?) stitch 2 layers of leather, but when I attempt to stitch four layers (2 layers & 2 skived-layers glued together), the top thread struggles and starts to tear itself up.

I have the servo set pretty slow, but I don't think that should affect the torque of the needle press.

My first guess is that the needle is undersized. I'm using #30 Venus V-Spun thread. The needle is a #14 1134 LR Schmetz.

As a double-check I show a diagram of the needle orientation and thread feed direction. I believe the scallop should face right and that the top thread should enter from the scallop side.

Below I link to an album that demonstrates sewing 2 layers and 4 layers.

Album showing that I can stitch 2 layers of leather ok, but 3.5/4 layers the stitch fails.

I am able to get Groz-Beckert 134 LL CR 90/14 100/16 and 110/18.

The heavier gauge needles, 134 LL CR/134 KK LL CR 120 and 134 LL CR/134 KK LL CR 130 apparently have a shorter shank. They're gong to give me some samples of those two, I'm not sure if there is flexibility to adjust the Pfaff-471 to use shorter-shank needles, but at least a #18 size should be a helpful start.

-

On 10/23/2019 at 1:34 AM, Gregg From Keystone Sewing said:471 takes system 134, or 135X7

When the designate a cut point, as in this case, the system needle changes for example here 134LR, 135X8 RTW,

In this case, LL is a cut point needle with an hour glass shape. CR I'm not sure and can look this up later.

134-35 are very different needle, but the needle shank will will fit the same with the 134.

11 hours ago, Wizcrafts said:I have a few spools of Serafil bonded thread. It isn't as strongly bonded as Cowboy thread. The stitches look looser to me.

The Strongbond looks comparable to what most of us in the US are using for sewing leather.

Thanks. When you refer to the 'bonding' of the thread, what physical characteristic are you describing? I'm guessing it's how tightly the filaments that compose the thread are 'stuck together' somehow? Or maybe how easy it is to tear the thread?

-

7 hours ago, Constabulary said:Wiz, right to left threading is correct when the hook tip is on the left side. Problem is the needle scarf facing right instead of left. With other words turn the needle 180° and start again.

8 hours ago, Wizcrafts said:Check to see if you threaded the needle backwards. Your drawing shows it threaded from right to left, from the scarf side to the rib side. That is backwards!

You should be using bonded nylon thread to sew leather. The Venus thread you have is for cloth garments. Your needle is very small as well. To sew 2 layers of soft to medium temper leather you should use #69 (T70) bonded nylon thread with a #18 leather point needle. Sewing 4 layers calls for moving up to #92 bonded thread with a #19 or #20 needle. This assumes that the leather pieces are each about 2 ounces thickness.

Hi there. Regarding Bonded Nylon Thread... I am in Singapore, so I'll need to find something here. Are there other names this thread would go by? One thread I have access to is Serafil, which they call 'polyester continuous filament' and recommend it for things like shoes.

From the makers of Serafil, there is also Strongbond, which sounds more like the type of thing you're talking about.

-

7 hours ago, Constabulary said:Wiz, right to left threading is correct when the hook tip is on the left side. Problem is the needle scarf facing right instead of left. With other words turn the needle 180° and start again.

Ah thanks. I was wondering about this. I felt like the scallop (scarf?) should face the hook, instead of away from it, but I thought i was reading the opposite in the manual (who's pictures are impossible to see)

-

Experimenting with my Pfaff 471. I can dependably(?) stitch 2 layers of leather, but when I attempt to stitch four layers (2 layers & 2 skived-layers glued together), the top thread struggles and starts to tear itself up.

I have the servo set pretty slow, but I don't think that should affect the torque of the needle press.

My first guess is that the needle is undersized. I'm using #30 Venus V-Spun thread. The needle is a #14 1134 LR Schmetz.

As a double-check I show a diagram of the needle orientation and thread feed direction. I believe the scallop should face right and that the top thread should enter from the scallop side.

Below I link to an album that demonstrates sewing 2 layers and 4 layers.

Album showing that I can stitch 2 layers of leather ok, but 3.5/4 layers the stitch fails.

-

@Gregg: Locally I can get Groz-Beckert 134LR needles, although i buy them directly from GB (minimum order size 100 needles, so way more than i need, but still makes more sense than buying small lots overseas to ship here). What size(s) should I get, the GB Distributor carries a broad range. A lot of my fabric-bag projects i use size #20 or #30 thread. In leather projects, i'd make wallets and bags. I'm not making massive stuff like a saddle or osmething.

-

I bought a used Pfaff 471. It came with a handful of needles and I had a technician tune up the machine. Works well.

The needles that came with the machine (and work) are Schmetz with the codes:

- CANU: 20:05AX1

- NM:90 Size: 14

- 1134 LR

- 135x8 R TW

- PFx134 LR

I needed more needles (and stronger needles) so the technician told me to use DPx35 Needles.

I bought some Schmetz Needles with the codes:

- CANU: 32:10AX1

- NM: 120 Size: 19

- 134-35 LR

- DPx35LR

These do not work. The miss stitches etc. I realized that they're roughly 3mm longer than the 20:05AX1 that came with the machine.

The manual says "Use System 134 LLCR Needles only"

So I don't know if any of the needles I have are technically correct. Were the original needles not exactly right either, but the machine was adjusted to suit them? Is the manual using an antiquated code? (the manual is from mid-1950s). What needle system should I be using?

-

I had the opportunity to buy a used Pfaff 471-755/01 postbed machine from a shoemaker. Not very familiar with it, and have no manuals or reference materials. Wondered where I could find operator and repair manuals for the thing. Also generally wondering if there is any good coverage/reference on this machine online. It's old, the serial number is 529967. Manuals I found online started at serial number 2-million somthing, so it's pretty dated. Ran smooth like a beast when I tested it, though.

-

I want to make a carry-bag where the top of the side pieces are round ('doctor' style bag?) and the zipper is on top. I would like to hide the edges, so I guess that means hand-sewing it inside-out. I experimented with some scrap today to see how it might work. It came out ok, although the roundness wasn't perfect, and the joint seems a bit fat.

I cut some darts into the edge -- I think that might improve the roundness some. I'm also wondering if I should skive down the edges so there isn't so much bulk to fold (but it's a bag -- so I don't want it to be too weak...). I ran my stitching line 5mm along the edge

What are best-practices in sewing this style of rounded connection in Any advice on designing the pattern in-general?

outside of the experiment. Edge is sort of bulky-looking.

Sergers with automatic thread tensioning

in Leather Sewing Machines

Posted · Report reply

I tested a 'Baby Lock' serger yesterday. It had automatic tension adjustment. It worked well. I replaced the typical gossamer thin garment thread with some serafil 30 and it serged just as perfectly with the far heavier thread, needing zero adjustment.

Am really curious how this works? On youtube most of the videos are aimed towards my mom's audience, so no one cares to explain technically/mechanically how this works. The closest clue i got was maybe it calibrates how much length of thread it feeds during the stitch, as opposed to relying on a tension adjustment. Searching google just leaves me with blogspam.

I wondered if any of the machine experts here knew how these automatic tensioners worked so well.