NewfoundlandLaw

-

Content Count

53 -

Joined

-

Last visited

Posts posted by NewfoundlandLaw

-

-

12 hours ago, Kcstott said:That’s still more money than I care to spend anytime soon. But you never know.

A few years ago I was looking at a tippmann boss. I just skipped over that all together and bought a cobra class four.

I couldn’t be more happy with that machine.I did the exact same thing.

I have to say that I am 100% happy with both my Cobra Class 4 and TechSew 2750 Pro. Awesome machines backed by awesome companies.

-

2 hours ago, Kcstott said:I feel like John Carter looking at this thing price tag has to be $10K or more nope just over $6K USD

Being a Canadian who recently purchased a Cobra Class 4, that price seems reasonable. (Shipping, Custom's and the weak Canadian Dollar really adds up.)

I envy Americans when it comes to these purchases.

-

Hey All

I got lucky today and scored a good working condition Bonis "Never Stop" Model complete with table and motor. To make it even better, I also got 2 great condition matching Bonis machines I can use for parts or use as well. (The "spares" also seem to be in good working order.) I also got a bunch of spare Bonis needles, thread, etc.

Since I live in a very remote area with no local leather workers, this is an extremely lucky find. (Didn't think there was a Bonis machine for 1500 miles.)

No idea how old it is.

I've attached a picture of the working machine and one of the spare machines.My plan is to completely refresh the wooden work surface and sand/polish the stand frame. (Might get it professionally painted, but haven't decided yet.) I also plan on doing a thorough clean, polishing and lubricating of the machine and case. I ultimately want to use it for Seal Fur, but want to make a restoration project out of it first.

Anyone ever try to bring one of these old machines back to new-ish condition? Any hints?

Also, is there any way to date this machine?

-

On 2/28/2020 at 8:12 AM, Gunnarsson said:The main casting on most sewing machines is probably good for it. And all the rest is just parts you can replace, as required.

I think with regular oiling/maintenance my Cobra Class 4 or TechSew 2750 would easily out-live me. It's really cool to see machines made in this day and age built with such quality.

I am a fan of new technology. I look at my Brother SE600, (cheap $500 machine which is extremely popular), and would love to have even 10% of its options on a new leather capable machine. Even a small selection of stitch patterns would be cool in a sub $5K machine.

As for Bernina, they are a very high-end Swiss Company with an amazing reputation in the sewing world. They are the only fabric sewing machine company I know of with customer service on par with companies like Cobra, Cowboy or TechSew. Their machines are very pricey, but the build quality is stunning. The only thing I can liken it to is my Wife's AMG Merccedes in terms of overall engineering.

While I do long for a more feature laden machine for under $5k, I've been truly amazed by the customer service offered by TechSew and Cobra. If I had to choose between high-tech features or stellar customer service, I'd pick customer service every time.

-

Hey All

As a newbie to leather working, I have purchased 2 new heavy duty leather machines in the past year. The first was a Cobra Class 4 and the second was a TechSew 2750 Pro.

While I absolutely love the quality and bullet proof nature of these machines, I often use a Brother SE600 to attach edge strips to the top lip of my bags. (Usually simple binding edges.) Switching from the SE600 to one of my dedicated leather machines makes me feel like I've gone back in time 100 years. This gets even worse when I use my mother-in-laws Bernina 570QE with crazy options like digitally adjustable pressure controls.

Do you guys/gals think heavy-duty compound walking foot machines will ever go "high-tech" with LCD screens, multi position programmable foot controllers and dozens of stitch options? I was originally hesitant with high-tech sewing machines, but after using the SE600 and the Bernina 570QE, I have to say that things like automatic stitch locking and thread cutting sure are nice

-

53 minutes ago, kgg said:I know nothing about these machines but was wondering how you are doing with the snow. Getting 76 cm (2 1/2 feet of snow in 24hrs with winds up to 155 km ( 96 miles) an hour. In my 45 years of living and growing up in St. John's (oldest city in North America) I cann't remember that amount of snow in such a short period of time.

Stay warm and safe,

kgg

We are keeping positive. Most of the Island is shut down as we have 15 foot + drifts everywhere. That being said, you can't kill a Newfies spirit so we will survive.

-

Hey All

Does anyone have any experience with the CraftTool Pro Rotary Cutting Machine from Tandy? I posted a pic of the model below.

I want it to be able to cut single strips of 8-12oz Veg Tan, (cut single 3.0 - 4.5" strips), but I'm worried it might not be strong enough to handle 12oz Veg Tan.

Given the machine is rated up to 10oz for cutting multiple straps at once, can it cut a single wider piece of 12oz? (It would only have 1 cut into 12 oz as opposed to 4 cuts into 10 oz.)

Any info is appreciated as I live quite a ways away from a Tandy Store.

-

17 minutes ago, MikeRock said:What are the dimensions? Round hole punch, followed by slot punch (will have rounded ends), then two opposing cuts with strap end punch? I wonder what it would cost to make two dedicated punches? If you are sanding or grinding to finish, would just a single round punch make the outside, then grind it down?

I want to both make the oval shape and the inner tang slot simultaneously.

If I can get the size of the oval right, it reduces the overall grinding required.

-

Hey All

I am a knife maker who has been making a lot of stacked Leather Handles lately. (I usually have loads of veg tan scraps so it kinda seems natural.)

I am getting tired of cutting each oval piece by hand and then cutting a slot for the tang by hand. A simple mallet die or even a press die would do much better and be infinitely faster. Every knife needs 20-35 of these pieces, so the work really adds up

Anyone know where I can get a die that will cut leather pieces to make stacked leather handles?

For reference, this is what the the leather pieces should look like after they are cut:

-

Thanks for the tip on the snap, never thought of that.

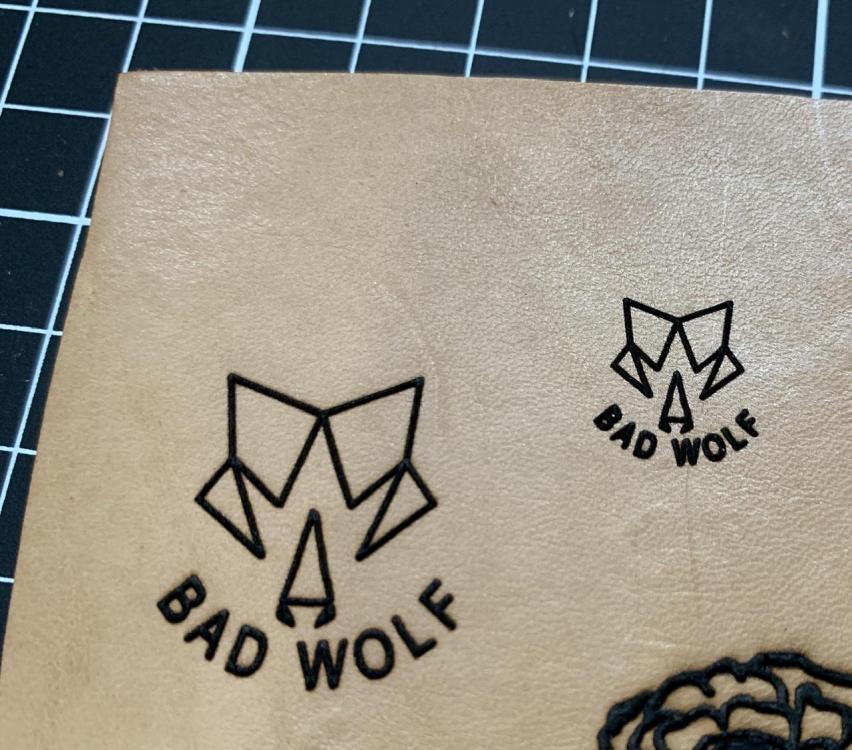

I use a toothbrush to wipe the ash out of the engraving lines. As long as the leather is dry, it cleans up nicely. I've also noticed that if you adjust the laser duration and power just right, you get very little ash.

I have 4 other wood designs and I'm working on one of my own. It will take a lot of trial and error, but I'm determined to get this right.

PS: Thanks for noticing the mosaic pins. I like to set my work apart by using unique materials and paying unending attention to detail. Probably why I'm loving leather work (and this forum), so much.

Thanks Everyone!

-

Hey All

So tonight I finished my first attempt at making wood patterned leather with a laser engraver.

I used a GanGou laser I purchased on Amazon. It is fairly cheap, but with some fiddling, I now have it engraving like a champ.

Here is a link to the machine:https://www.amazon.ca/engraving-machine-Engraver-Off-line-engraver/dp/B07QQ2N7C8

I simply burned a 5.5" square section with the pattern, and cut my leather from there. This section gave me enough to make 2 sheaths for knives I recently made

I burned the wood grain a bit deep, (about 0.75mm), to give it a little more depth and texture.

I've also used it to burn my Custom Knife makers mark on my sheaths, and it has turned out beautifully. Overall, I'm very happy with this little machine.

-

1 hour ago, JLSleather said:So... WHAT was the issue?

When I bent the needle I messed up the smooth feed dog and put a small burr on my timing hook. Timing was ok, but during the conversation with Cobra, I reduced my lower bobbin tension.

So, not only did I get the problem fixed, I got my machine better dialled in for sheath making.

WIN WIN!

-

After talking to Cobra directly, I not only have the issue fixed, but my machine now makes better stitches than ever before! Gotta say, blown away by their awesome service!

-

12 hours ago, RockyAussie said:A bit of emery cloth would be better than the file but I would suspect that you may have knocked the timing out. Double check that the needle bar has not moved up before any other adjustments.

How do I check the timing?

-

Hey All

My new Cobra Class 4 has been running like a champ since I got it in October. So far it has made about 20 sheaths and 10+ seal fur bags. (Not to mention about 16oz's of practise 277 stitching.)

Tonight I accidentally bent a needle while sewing a sheath and it looks like it contacted their bottom feed plate. It was a very light contact as I was going slow, but it looks like I marred the the piece. It left some very small marks on the piece, but now it seems like every time I try to stitch it frayes and breaks the stitch within 2-4 stitches. I've attached a picture of the little piece and the thread below.

Is this little piece the problem? If so, order a new one? Also, can it be fixed with a Jewellers file while I wait for a replacement?

-

Hey All

So, it will be a about 1-2 years til I can get the Hydraulic Press I want, (TechSew TS-12), as I'm currently building a new home with a 1,100 square foot "hobby room" in the basement. I don't have room in my current 92 square foot leather room. (Plus I don't want to bother wiring a 220v outlet to my current room when the new place is under construction.) Seriously, I bet I have less than 30 square feet of unused space in there

I have a little Tandy Press for small jobs, but want to be able to use larger handbag sized dies. Shipping a Weaver Press to where I live is prohibitively expensive, so I decided to make my own out of a hydraulic Shop Press.

I picked up a bench-top press today for $200 on sale and am now looking at a table to mount it to. I have a pair of 1/4" thick AR500 plates and a 3/4" HDPE cutting sheet ordered. (All are 23"x23" to take advantage of the full width of the press.)

I see a lot of people have built their own presses. Would anyone like to share their builds or have any advise on how to build a good homemade press?Here is the Press I have and lower cabinet I plan on using (The cabinet will have feet instead of wheels.)

-

Hey All

I am looking for a good swing away Or 110v electric press that will allow me to use larger cutting dies. (Mainly purse dies.). I already have a Tandy Press, but it can't handle the larger dies I need to use for Purses, etc.

I like the Weaver Mighty Wonder, but it only cuts 8"x12". That's on the small side for my handbag dies.

Are there any options for a swing away Press that has a larger cutting area? Alternatively, what options do I have for a 110v Press that can cut Leather with larger dies?

Thanks All!

-

On 12/12/2019 at 12:37 PM, Sonydaze said:I saw your post, looked at the unit and bought one. (lol I live close enough to a store to do a return)

I set it up yesterday and gave it a quick test run. It works well! I think at the sale price, it is an excellent deal.

My negatives on it:

Does not have self centering guides. The single guide works okay, but you have to adjust it (correctly) if you change width. The measuring guide seems fairly accurate but is in millimeters.

Both dies have a round end punch good for up to 2". Okay for the buckle end, but I don't like it for the billet end.. not as pointy as I would like. However they do offer an English point model ( https://www.tandyleather.ca/en/product/craftool-pro-tipping-end-punch) For $155.29.

Is the English point punch different than the end that comes with the machine?

-

Hey All

So, I've been pulling my hair out trying to make nice, clean and straight cuts on leather projects. I'm getting better using a thick fabrics ruler, cutting mat and a head knife, but I always feel like there is room for improvement.

By day I'm a lawyer who owns a small firm. I noticed that in my copy room there was a 24" Guillotine Paper Trimmer that never gets much use. It's an Xacto brand cutter and weighs 25+ lbs. When my office manager left for the day, I loaded it up into my truck and headed for the workshop. (I own the damn place, but she still scares me...

).

).

To my surprise it works amazingly well on any leather under 8oz. It even glides through seal fur pelts like butter, giving perfect straight cuts every time.

Has anyone ever tried a commercial paper cutter on leather? If not, give it a try. The results are amazing, so I thought I'd share.

-

Hey All

Looking for a good source for leather cutting dies. I'm specifically looking for small purse, courier bag and wallet dies to simplify the cutting process.

Anyone know a good place to buy leather dies?

Marc

-

Hey All

I make a lot of Dog Collars, Belts and Straps and I am always obsessed with getting a perfectly symmetrical tips and holes. (I am A LOT OCD.)

I see Tandy Leather has their Pro Tipping machine on sale. The link is here: Pro Tipping Machine

I think a few different places sell the same press under different names, but I can't find many reviews or videos. Nearest Tandy Leather is 3000kms away so I can't just go see it in person.

I'm wondering if anyone on here has tried it?

-

Hey All

I've decided it might be time to buy a strap cutting machine for belts/collars/handles/etc. I really only need to cut from 1/4" to 2" straps so a huge machine would be a waste for me.

My leather workshop is small so I've been looking at the smaller power cutters. They take up less room and are easy to move.

I like the look of the TechSew 2020P and the fact that it has a foot control and a presser roller. It seems like this is a common strap cutter that is sold under many different company names. I also like the price of about $1K Canadian and Ron at TechSew seems like a knowledgeable guy.

Here is a link to the machine: TechSew 2020P

Does anyone have any info on these machines? Any recommendations of other strap cutters I should consider?

-

2 hours ago, Wizcrafts said:It would if the bag is made with fur and the hide isn't too stiff.

Thanks Wiz. Your knowledge is always invaluable!

-

12 hours ago, DrmCa said:I am so glad that I own an old Bonis Never Stop fur machine. It is super awesome for furs and also works well on light leather for gloves and such.

It helps to have a compressed air gooseneck blower too. I do not yet have it set up, but contemplating, as hiding hair between the pieces with my fingers is taxing.

If you are serious about sewing furs, you should definitely look for a fur machine as they produce much better results at higher productivity. At the end of the seam you just tear off the workpiece instead of cutting.

One thing to keep in mind is that machines work well with the weight which they are designed for. If you step up your minks and try to saw lamb, you might be all right, but if you try sheepskins you might start breaking needles. Check out Bonis web site for an idea how many different types they make.

Needles are quite unique and you have to buy them in boxes of 100 most of the time.

Any questions re my Bonis, reach out!

I see they make a really unique stitch.

Does this type of stitch work for sewing things like handbags?

Struggling with Footprints

in Leather Sewing Machines

Posted · Report reply

Hey All

I need help:

I am starting to get used to making leather sheaths for my handmade knives. The Cobra Class 4 was a big learning curve but I can't imagine leather work without it now.

My only issue are the tiny prints the presser feet leave on my leather. I've tried flattening them out with a bone tool, but they are still noticeable.

I have a bunch of products like Mink Oil and Snow Seal, but I'm not sure how to buff the tiny imprints out completely.

Here is my most recent project. I flattened the foot prints with a round bone tool, but still have some noticeable marks. It is a good example if the marks I am left with. (Black edges are airbrushed with an Iwata Eclipse.)