Scootch

-

Content Count

143 -

Joined

-

Last visited

Posts posted by Scootch

-

-

-

Looking for a Krebs splitter.

Thanks,

Scott

-

The title pretty much says it all. The only one I've found searching is nickle free and seems to be sold under a few different makers but it doesn't appear to be the quality of over seas made buckles. This buckle also isn't marked as American made.

I'm looking for 1.5" ss roller buckle that's American made as well as American made Chicago screws.

Thanks,

Scootch

-

Thanks for the replies. The photo Tugadude posted is very similar to the one I'll be working on. I was going to cut a few belt blanks out of the back so I'll cut a few 5/8 strips while I'm at it.

Thanks

-

Hello,

A friend asked me to replace the leather on his side pull. I have an uncut side of HO Latigo to use. From where should the straps be cut: the back, the shoulder, the bend or above the belly where it's no longer flanky?

Thanks,

Scootch

-

I have a couple of BK and a couple of Clay Miller swivels. They all have different blades installed. I do find myself favoring the Miller. Whatever you go with, buy several blades.

Scootch

-

If anyone has one please let me know.

Thanks,

Scootch

-

I've been waiting for one of his knives to post on his website for months. Two weeks ago there was a Klenda in stock. It wasn't the one I was looking for but guess I should have bought it. Clay Miller also posted one a little while back with his custom handle material. The time I talked with Terry he said he wasn't taking orders and to keep an eye on his website. That conversion took place in April of this year.

Scootch

-

Your holsters look nice. My preference would be to use a larger edge beveler for a little more roundness. On the bottom right corners I would adjust the pattern to where there is enough leather that you can add one horizontal stitch so that your perimiter stitch line doesnt run into the vertical stitch line too soon. Practice on your method of developing your stitch line. The gun fits well on the trigger guard but you're a little off on the dust cover stitch line. Again, nice job.

Scootch

-

I'd start by looking at concealed carry purses for women. Also find out if your customer wants a separate easy access compartment or if they want it in the main compartment. Depending on what they want will help determine how much retention you need for the holster. An external easy access pocket might require a fully retained holster where as a deeply concealed pocket in the main body would not.

Scootch

-

Do you have a style or pattern you're interested in? I find the smaller the stamp the more difficult it is not to have a crooked one, especially a smaller stamp on thicker leather.

I also do better making my first row of stamps on the same side of the layout line. Some folks alternate each side of the layout line on the first pass. I find this approach more to be difficult.

Scootch

-

For sharpening my round knife I use a mouse pad atop a granite precision ground surface plate wit automotive sandpaper in the 400 to 600 grit range then strip with green rouge. If you dont want a convex edge, skip the mouse pad and wet the sandpaper so it'll stick to the surface plate.

I find with stropping my tools seldom need real sharpening however I dont use them everyday.

I have a spyderco medium ceramic in my amazon cart but havent pulled the trigger yet. They are supposed to be a good all around stone.

Scootch

-

Is this the common wooden type of cutter? I've never had a problem with curving but only on the last 3 or 4 inches of the strap just before it releases from the cutter. One issue I had has the strip would get slightly wider as I cut. The part that held the blade would slip a little under the wing nut. The firmer the leather the more it would slip. Keep a sharp blade, tighten the wing nut with pliers and set the opening width to where it's not pinching on the leather that way you're not pull harder than you need to.

Scootch

-

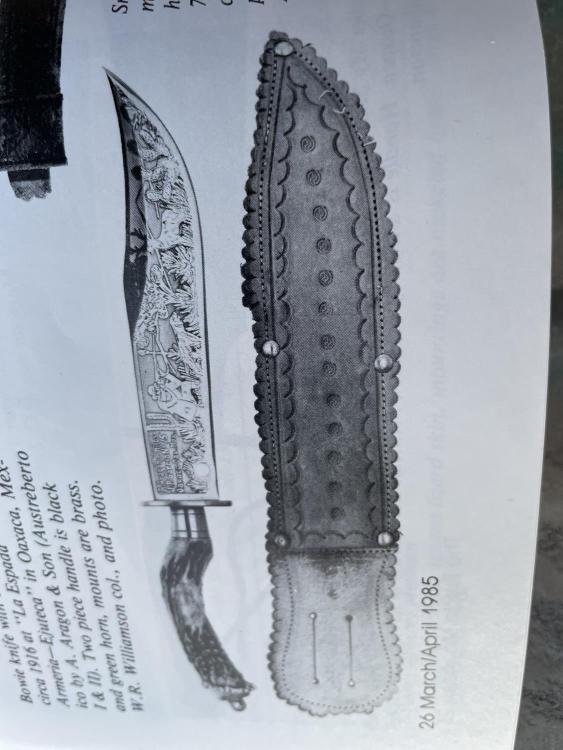

8 hours ago, RVM45 said:Doggone dude, I know the emphasis is on the leather, but when you have a unique knife, it would be considerate to show at least ONE view of the naked blade...

7 hours ago, tsunkasapa said:

I found this one for you all. It's with the original sheath. The knife is German made.

Scootch

-

Are you asking what tools you need to tool oak leaves as pictured?

Scootch

-

Nice go at it. A little while back I drew my first after watching Don's course. I started through it a second time but realize now that I got distracted! The biggest issue I've found is beveling makes every thing smaller or thinner so draw everything fatter than you think it needs to be.

Scootch

-

A friend of mine filled an american gator tag last year and asked me to make a holster. I've finished the holster to the point it either needs a finish coat or not. I don't see that its necessary but I'm ignorant to the topic.

Do items made from gator benefit from a top coat or not? If so, what's recomended?

Scootch

-

Super nice!

Scootch

-

The first 7 holes were drilled. After that all the holes were marked with pricking irons but just pricked. I continued about halfway down the long side with the awl and stitching pony. From that point I was pretty frustrated and laid the scabbard flat on a vinyl pad and tapped the awl through with my light mallet. I was using a BK awl handle and blade. Regardless how tight the collet was the awl blade would continue slide into the handle. My 8.5 spi irons have long thin blades and i'll usually go though the first layer and welt with them but these Goods Japan irons make a huge hole.

I didn't think about using the Boss. Usually on scabbards and holsters I'll hand sew because the distance is short and it its not worth trying to set the tension on the Boss.

Thanks,

Scootch

-

Thanks for the input and compliments. Be blessed.

Scootch

-

My dad asked me to make this for his friend. I learned a lot and had fun. Other than a few pocket knife sheaths and a small fixed blade EDC sheath this is it. I had to drill the holes on the top long edge because I couldn't get an awl through it and the stitch line was wiggly until I figured out how to get through the the thick leather leather in a reasonably straight manner. Any comments are welcome, constructive or otherwise.

Scootch

-

18 hours ago, Spyros said:By the way Scootch, don't be put off by the discussion and the apparent lack of clarity and the variety of opinions on pricing, it's perfectly normal.

I do this professionally (pricing of products and services for a multinational organisation) and I can assure you it's exactly the same discussions over there as it is here. There are always people who say we should price things cost + margin and there are always others who say we should ignore costs and price them to match the market. Both opinions have their merits. It's good to listen to both but ultimately you will have to make your own decisions based on your particular business strategy, product and market. And keep in mind pricing is not an exact science, there's a bit of an art and a gut feel to it.

Not put off in the least. I'm please with the dialog! Good stuff.

Scootch

-

4 hours ago, JLSleather said:That's a very nice lookin' belt

STILL, your belt is overall good looking, clearly involved some planning in the making, and except for the very tip, the stitching is quite good (that's another day).

Thanks for the feed back. I don't think I've nailed the stitching on the tip since I've been using the Boss. I think you need thee hands to operate that stitcher.

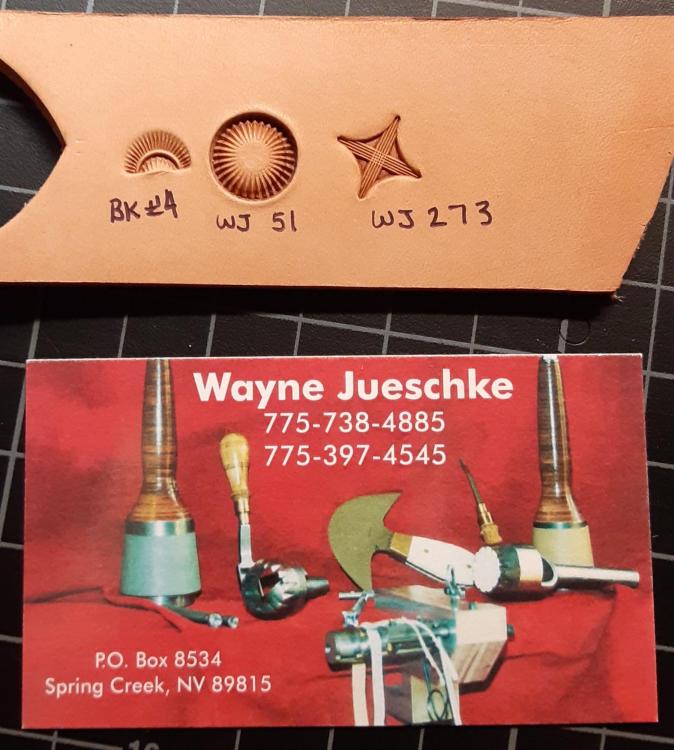

8 hours ago, noobleather said:what stamps did you use?

2 hours ago, RemingtonSteel said:Beautiful belt, you have got me wanting to make one with this pattern again. I have to ask though, who is the stamp manufacturer and what is the number of the geometric box stamp. That particular one creates a very nice cross hatched look in background and I have not seen it before?

The arch is a Barry King size 4, the flower center and box are from Wayne Jueschke. It was sheer luck the flower center was the correct size. The pattern didn't develop for me until after a few hours of tinkering with the stamps. They are spendy but he has many stamps that are not duplicated elsewhere. He's was recommended to me by a saddle maker. Bruce Johnson, on this site, also carries his tools and will allow you the option to pay with a debit card as opposed to mailing a money order.

49 minutes ago, TomMeyers said:Your work is very! Nice. I would have punched the holes into the pattern rather than by measure.

I agree that would have been a extra nice touch. I spaced these at 7/8 because its a kids belt and used the second hole instead of the center hole for measurements to give him a few more years of use...

Thanks for the comments. This was the first time doing a geo pattern. There isn't much room for error with the box stamp. It seems leather burnishes its best when the surface of the leather has dried to the point it's stiff but it causes my stamp to squirt a little bit, sometimes, upon striking with a maul. I'm not sure what to do about it unless I sacrifice a little burnish and dampen the leather again. I was wondering what tools might be used to clean up the oddities after completing a geo pattern? I tried a modeling tool in a few spots before antiquing but I wasn't satisfied with how it looked.

-

David, Bible binding is an interest of mine as well though I've yet to tackle one. When I do, I plan on sewing the cover. However many fine bibles are simply skived, folded and glued. If you are new this might be a good option. There's a lot to learn. There's a bible binding book by Diego Caloca Jr. His book teaches glueing without the stitch as well.

If I were going to sew I'd use .6 ritza25 thread and a 004 harness needle with 3.0 irons, mainly because that's what have. Just make sure the spacing from the edge to the stitch line is appropriate for the size iron. You could also buy a small awl and spacing wheel and not use an iron.

Looking for a stamp

in Leather Tools

Posted · Report reply

This is what I have. I'll try to get the owner on the magazine to take a better photo.

Thanks