Marcremb

-

Content Count

34 -

Joined

-

Last visited

Posts posted by Marcremb

-

-

Hello. the top thread on my Pfaff 145 h3 is to tight . I mean when it turns around the hook, like if the take up lever would lift the thread to soon during the cycle.

I hook timed it correctly (0 feed, 1.6mm rise and hook in center of needle and scarf) but May be the top and bottom mechanism timing is not correct. I can't find any information on this pfaff 145. Does someone knows something about it?

Thanks

-

You are all right about servo motors. l have 6 sewing machines with servo motors on and it works very well and 2 with clutch motors, my overlock and my Mitsubishi lu2 410 Automatic walking foot sewing machine that as this 3 phases 220 volts motor on that i recently got for free.

Because it as an Automatic system on it that wanted to use to go faster i decided to leave it with the 3 phases clutch motor.

So i bought this New converter on the market : DPS (digital phase shifter) that concerts 220 volts single phase to 220 volts 3 phases.

It works perfectly at a low price. It is made in South Korea . I bought it at Ebay.

Just in case you want to have a faster set up than adding a servo motor.

I am very happy with the device.

You can look at the YouTube how to connect it

-

Hello Parry tack. I have a Singer 144Wsv35 that as a pedal reverse on it.

Here in Canada, a good condition long arm machine sells for more than $7000..

Yes 7K. At a Dealer. On Facebook (Market place for around $5000 without the front wheel like yours.

I paid mine more in Shipping than the price of the machine because it was in bad condition, and the owner didn't know that it had a reverse on it because their was'nt any pedal.

So in U. S. I would try to sell for $4000 and minimum $3000 if it as a reverse mechanism on it.

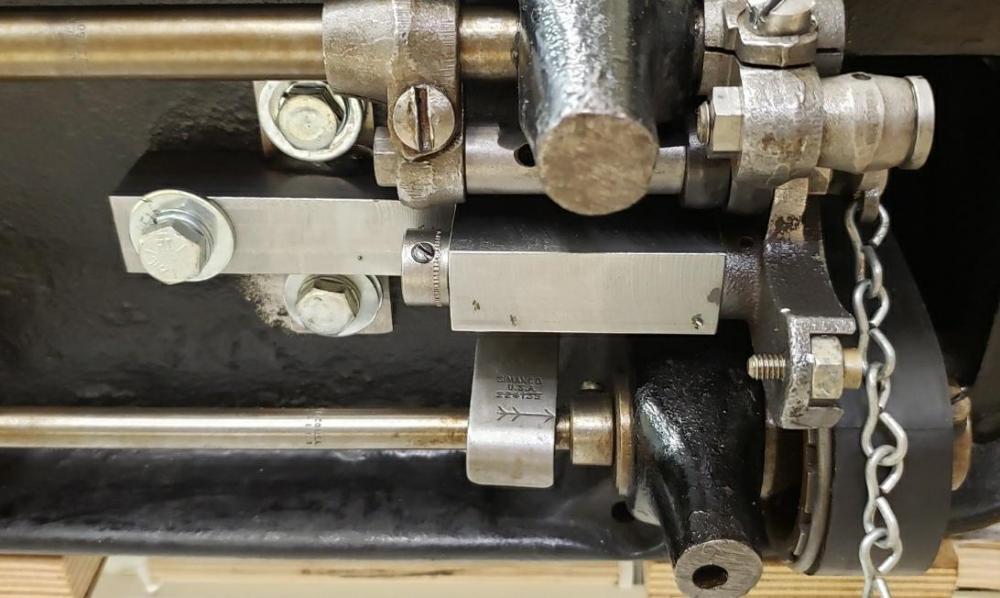

On the second picture you can see what the mecanism looks like

-

On 4/12/2011 at 10:18 PM, Wizcrafts said:If the motion feed crank has a worn down feed puck, you can braze bronze onto it, then shape it with a file, then buff it to a polished finish. If you take your time and get the clearance and ends shaped just loose enough to allow the crank to turn 360 degrees, you will get the maximum stitch length possible (~5/inch). I did this to two Singer patchers and both gave 5 stitches per inch after the bronze build up job.

Hello Wiz

On 4/12/2011 at 10:18 PM, Wizcrafts said:If the motion feed crank has a worn down feed puck, you can braze bronze onto it, then shape it with a file, then buff it to a polished finish. If you take your time and get the clearance and ends shaped just loose enough to allow the crank to turn 360 degrees, you will get the maximum stitch length possible (~5/inch). I did this to two Singer patchers and both gave 5 stitches per inch after the bronze build up job.

Hello Wiz (dont know your first name)

My first name is Marc . I like your participation to the forum. You got a lot of experience their. Really appreciate it.

About the Singer patcher stitch length problem, i have the same issue on my 29K171. You wrote bronze build up.

Is it possible please to see a picture of which part you've done it?

Thanks

-

Hello I am almost New to this forum .

This reply is late but in case that you dont know, those 220 volts motors work on 110 volts. I got 5 of them on my actual machines. I like them alot. Their is a feature that this motor have that others dont have.

When i kneel the pedal the motor turn the machine until the needle gets up (out of the sewn thing)

I had 1 on a Juki lu 563 that i sold with it. Fabulous motors.

If you need more power Just connect it on 220Volts but for the juki lu 563, 110v does the job.

-

On my Singer 144 W, the bobbins are jumbo bobbins and they are expensive.( horizontal hook, top load)

When i sold my Juki lu 563, i tried the bobbins that have smaller diameter and width then the 144W and they work perfectly without any issues with an under bobbin spring

The most important thing is that they have the same diameter center hole and the spring under it.

-

-

-

Great job! I didn't know that their was sewing machines for left handed...

It needs a minimum of sewing machine knowledge their.

I Wonder.... Are you a left handed handy man?

I have worked 20 years ago for an Upholster in Quebec City that is left handed. He as to use sewing machines that are all made for right handed People. He was amazing to see sewing.

I can't image my self as a right handed man with a sewing machine on the left side....

-

16 hours ago, MtlBiker said:I have an art gallery and picture framing business. I only started sewing (of anything) during the first forced isolation period from Covid. Now I have several machines (not close to your 9 though!) and for me sewing was the only good thing that came out of Covid.

I'm curious... what 441 clone did you get? How do you like it? Have you seen the mods that @RockyAussie designed and sells for such machines? Everyone is raving about them.

Cheers!

Oh! So your a handy man. Art and picture framing. Artisan is both : art + handy work.

It's good to focus on something else than business.... It keeps the mind healthy.

I bought this used 3 months old Choice 441 China made. I paid $2400 from Ontario. A God's blessing because it sells here in Mtl for $4000.

I sold the table that was way out to large for my shop and made a height ajustable table for it. I made a slot at the other end of the pressure bar to be able to install Singer feet on it.

This machine sews more thick than my Singer 144Wsv35 (long arm)

All this to tell you that this machine is a must have to sew thick with a cylinder arm sewing machine.

And yes i bought the narrow feed dog and needle plate for it from the store that Brian (Rocky Aussie) worked on the design . Have'nt had time yet to install the kit on the machine.

But i can give you a review on it if you would like when installed.

But may be your talking about something else?

Sometimes i need to sew very thick during my Upholstery projects.

I sewed an 1-1/2" antique front seat edge piece full of packed hard hay (paille ou fouin) i have removed a part that releases the top thread tension.

It did pushed the machine to the extreme limit hoping not to brake it.....

-

12 hours ago, MtlBiker said:@Marcremb - Bien fait Marc!

Nice work and congrats on getting that machine working so nicely.

I guess you do professional reupholstering. Very nice!

Bonjour Mtl biker. Merci du compliment

Yes i do Upholstery for living. I saw the hand bags that you did. Very good work. But tell me please, what do you do for living?

-

13 hours ago, Dominicgetsgnar said:This is awesome! Love the ingenuity here.

it must have been quite the brain workout figuring this out.

Thanks. Yes it as been quite an expérience. I spended many hours on that machine but i dont regret a minute of it. Almost a terapy.

I would like to keep that one until i pass away.... 1

I forget all of my problems when working on those machines. I lovvvvve sewing machines. I have 9 different machines in my small shop.

I do Upholstery for living. I would like also to sew heavy leather if God permits. That's why i bought a Juki tsc 441 clone.

-

I have contact the China choice company and they told me that it is not ajustable. So i dont know about other juki 441 clones but mine is made like that. So i have to do with it.

-

Hello out there.

I am proud to show that i was able to add a reverse on my Singer post bed machine. I love this machine because it as a post bed walking foot.

It can sew at 3 stitches an inch and can sew up between 7/16 " and 1/2" with 207 nylon thread maximum.

With the reverse added and the lift up table it became the most versatile machine that i have. Flat bed and post bed and can sew very close to the edge (1/4" from the left side)

If it can help someone that doesnt have much space i will be glad that it goes around .

If you need any help please feel free to comment or ask questions

-

Hello Gavino

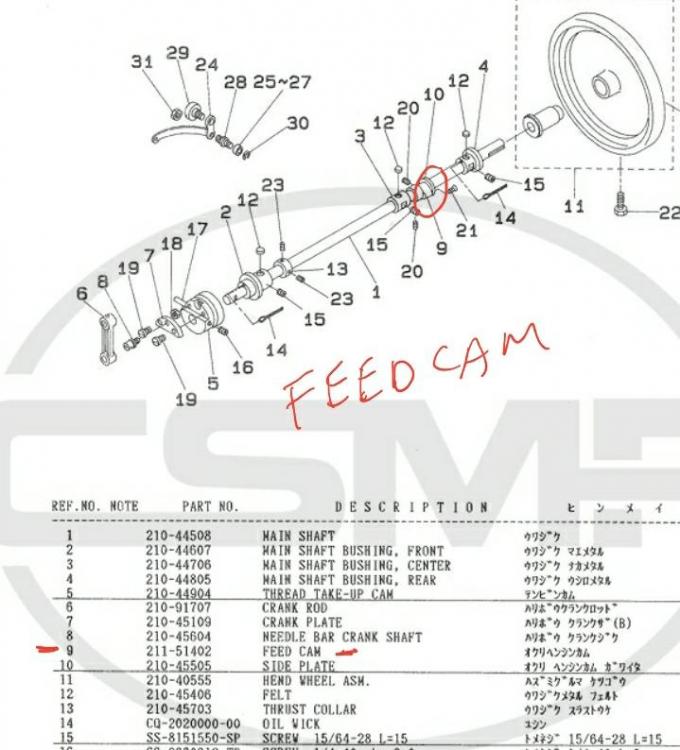

Their is a Duerkopp Adler 69-373 Service Instructions Manual

Direct link:

Page 19 hook setting (timing)

And here is a very well made video as usuall from Uwe about a Adler flat bed sewing machine(horizontal hook) . I know yours is a cylinder bed (vertical hook) but Just to learn the principles of timing a hook to needle

Also this man Mtrc crane (YouTube name). He does maintenance on a Consew 206 flat bed that as a vertical hook.

Just look at the first 20 seconds and jump to 45:24 for the timing needle to the hook.

Hope it Will give you self-confidence for fixing your machine in futur needs.

Wrong copy

This one :

-

Got it.

Precious information. Appreciate it. Thanks

-

-

Do you mean the inside Shaft?

From the access plate at the back close from the handwheel?

-

On 3/24/2022 at 7:54 PM, Marcremb said:Hello. I do Upholstery for living. I have 9 different sewing machine. I bought this 441 clone because i sometimes have to sew thick

To be able to sew Upholstery stuff on it i have cut a slot with my dremel at the other end of the presser foot bar so i can install any kind of Walking foot Singer feet . It works great. I am very happy about it.

The only thing is that the feed dog lifts to early before the needle and walking foot (needle foot) gets to the needle plate.

So because it's large (feed dog) it lifts the presser foot before the needle foot (walking foot) gets down to lift the presser foot

I would like to know where is the adjustment for that on the machine . Thanks

Do you know how to adjust my machine so the feed dog and the middle foot (walking foot) will meet at the top of the throat plate?

-

Do you know how to adjust my machine so the feed dog and the middle foot (walking foot) will meet at the top of the throat plate?

-

9 hours ago, toxo said:I agree Folker but they do what it says on the tin. I'd love to find an "unknown" maker who would make some for the "69".

Here's a thought. Would a 111 type presser foot bar fit in the 69?

How easy is it to take out the 69 bar to modify it?

I'm seriously thinking about trading in the 69.

I know getting adler parts is a voyage(travel) .... I bought parts for my Adler 068-4272 double needles walking foot. I search for a couple weeks on the net and locally. I kept looking on the net and found Kwokhing .

I needed 12mm between the 2 needles.

I wasnt able to remove the 5/16 " needle clamp so i mesured the diameter of the needle bar and found a pfaff needle bar + clamp from Kwokhing at half price of Ebay.ca . I Also bought feet and feed dog that i had to grind down. They have parts that are made of hardened stainless Steel.

The diameter and the lenght is important so if you look at different type of Singer original or clones and look for the part # on Ebay, evernice and CHPSMS give the mesurements on one of their multiple pages

But if you thinking on drilling your parts to fit one, you better go to an expert (machinist) to get it precise.

If your presser bar is a full metal bar and not a tube at the other end you could cut a slot as i did on the 441.

-

6 hours ago, CowboyBob said:I always adjusted uph machines so the needle is in the material just before the inside foot comes down & meets the feed dog,this way when the machine gets wear on it the inside foot doesn't end up pushing the material foward as it sews.

Thanks. I now understand that their are different ways to set up the entering of the needle.

Do you know how to adjust my machine so the feed dog and the middle foot (walking foot) will meet at the top of the throat plate?

-

5 hours ago, Wizcrafts said:The 441 machines are timed slightly differently than upholstery class walking foot machines. I have a Cowboy CB4500 and one of my buddies has a Cobra Class 4. Both of us set the feet so that the inside foot hits the throat plate at the same time as the tip of the needle. Failure to set them this way throws the reverse stitches out of sync. My upholstery grade 111 type machines usually have the needle hit first. But, I sometimes tweak these positions for different jobs.

But their is still a problem because on my 441 the feed dog meets the walking foot over the throat plate.

5 hours ago, Wizcrafts said:The 441 machines are timed slightly differently than upholstery class walking foot machines. I have a Cowboy CB4500 and one of my buddies has a Cobra Class 4. Both of us set the feet so that the inside foot hits the throat plate at the same time as the tip of the needle. Failure to set them this way throws the reverse stitches out of sync. My upholstery grade 111 type machines usually have the needle hit first. But, I sometimes tweak these positions for different jobs.

I meant higher than the throat plate

-

5 hours ago, Wizcrafts said:The 441 machines are timed slightly differently than upholstery class walking foot machines. I have a Cowboy CB4500 and one of my buddies has a Cobra Class 4. Both of us set the feet so that the inside foot hits the throat plate at the same time as the tip of the needle. Failure to set them this way throws the reverse stitches out of sync. My upholstery grade 111 type machines usually have the needle hit first. But, I sometimes tweak these positions for different jobs.

Thanks Wiz

I didn't know about the reverse sync. On those monster machines.

I have a 144W sv 27 with reverse that works as the Upholstery walking foot sewing machine. Walking foot even on throat plate sync with feed dog and the needle comes after. Same on my other machines.

.thumb.jpg.bd60920359c4db6b70aa683624eb1bfc.jpg)

Top and bottom mechanism timing on Pfaff 145

in Leather Sewing Machines

Posted · Report reply

Thanks Wiz. I will try those possibilities.

Thanks Fiber