-

Content Count

22 -

Joined

-

Last visited

Content Type

Profiles

Forums

Calendar

Blogs

Gallery

Store

Everything posted by BianVariani

-

My new leather belt strap cutter and punch. https://variani.com

- 2 replies

-

- leather belt tools

- leather belt punch

-

(and 1 more)

Tagged with:

-

I made my first one about 25 years ago. I'm sure that after my posts are public you will see other similar prototypes and ideas of the design above and now with sizable and changeable inserts. It's okay I got a patent on the above 25 years okay. Thanks for the tip Bruce, I will contact my lawyer and see if we need to crack down on more people steeling my ideas. All over the internet I see fake people selling my brand/products.

-

No one on the planet has a leather strap cutter that has changeable and sizable depth inserts. This is an original concept. Are you saying it is similar because it has a ruler and a guide? That's like saying the first electric Tesla car is similar to the gas ford car from 1920.

-

This is what I use for a portable leather belt strap cutter. I made a bunch of custom sizing inserts in addition to the design. https://variani.com https://www.instagram.com/varianibian

-

That depends on the type of stitching you do. For my belt above in RED I used 5 times the length of the entire belt.

- 11 replies

-

Here are a few custom designs that I made to cut the tip/ends of leather belt straps.

-

Ahh yes, I was editing the above in real time. Need time to update. And YES I'm known for grammar errors!!! I copy and pasted the fields as I was building the spot to input data. No big-deal. No I have not made any videos as of yet but it is on my to-do-list.

- 8 replies

-

- belt press

- belt punch

-

(and 8 more)

Tagged with:

-

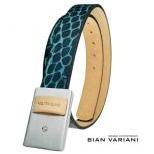

This is an example of a belt that I made with the machine above.

- 8 replies

-

- belt press

- belt punch

-

(and 8 more)

Tagged with:

-

This is one of my 1st belt press/punch that I made for leather belt straps. This is the Hole-Punch for the machine above!

- 8 replies

-

- belt press

- belt punch

-

(and 8 more)

Tagged with:

-

Right now I am building a custom marker design that will be more user friendly for my applications.

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)

-

I use different markers for different colours. No cleanup needed, just put the cap back on and put it in a ziplock bag.

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)

-

I have the air pressure end capped off with a bolt (not needed). You just can use the trigger and pump the paint to the felt.

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)

-

This will always work, but I need perfect pressure and flawless paint strokes so I built the concept with the linear guide.

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)

-

The problem I faced with my "Paint Gun Edge Painter Conversion" innovation is that it's too big and clumsy when your belt is sitting in 6mm groove and you need to get above it. The gun would hit the table BUT if you are free styling it and holding your product, then no problems. But I have better methods that work as well. Look at my post with the Spray Gun. All you need to modify is the tip. I customized everything in black.

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)

-

chuck123wapati Chuck123wapati, have you tried a solution like this before? I have built many different prototypes for edge painters and the felt concept with the groove works flawlessly.

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)

-

I'm a fashion designer by trade. At one point or another I think I purchased most available products that are used for hobbyists, professionals, and commercial/industrial machines. Most machines lack technical support from the manufactures and calling the retailers are pretty much useless (they are not designers or end users for the most part. In addition, most products come with a handful of problems and usually they do the job but not as expected. At the end of the day you are left with some form of disappointment. This was me for the first few decades as a designer. I took a few years off from the fashion-life and studied Mechanical Engineering, bought a CNC machine and tons of other tools and I started to design tools/machines that would please a professional fashion designer in the leather artisan-industry. Before that I was not very technical in terms of being a machinist, I learned!! I have created about 13 different types of tools, machines and gadgets that solve a few issues that I faced in the leather industry. Here is my Instagram with a few things I made: https://www.instagram.com/varianibian My Website: https://variani.com Email: bian@variani.com I will take a few pictures and try to explain my process for belt strap cutting and edge painting.

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)

-

As a Leather Artisan I have struggled with Edge-painting leather belt straps, so I engineered my own edge painting tools which work great and currently solved all my problems. Does anyone else have an alternative suggestions? I always love to hear and to learn from others and new techniques.

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)

-

- 11 replies

-

Custom-made Belt Press/Punch and dies. Instagram: https://www.instagram.com/varianibian

-

Instagram: https://www.instagram.com/varianibian/ 100% custom made original design. Currently I am using my CNC machine to custom build my new buckle designs. Does anyone know of a foundry that specializes in buckles?

-

Custom made belt-press, tip cutter and heat press that I made. The biggest problem that I solved in this build is that I created custom alignment guides so I know where to exactly position the belt during the process. More pictures of my work is available at: https://www.instagram.com/varianibian/

-

- machinery

- belt press

-

(and 8 more)

Tagged with: