-

entries

11 -

comments

3 -

views

23,830

About this blog

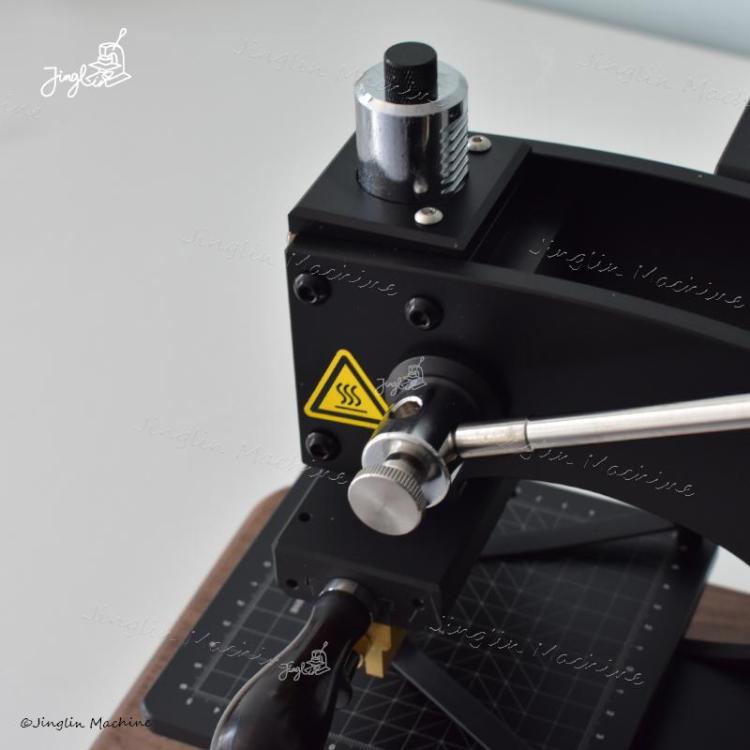

The hot stamping process involves four main steps:

- Heating – The machine's stamping die or brass plate is heated to a specific temperature, typically between 80°C and 300°C, depending on the material.

- Foil Placement – A foil sheet is positioned between the heated stamping die and the material.

- Pressure Application – The heated die presses the foil onto the material, transferring the design.

- Cooling & Peeling – After cooling, the unused foil is removed, leaving a sharp and vibrant imprint.

The stamping quality depends on precise control of temperature, pressure, and material compatibility to ensure clean, consistent results.

Types of Hot Foil Stamping Machines

There are several types of hot foil stamping machines, each suited for different needs:

- Manual Hot Stamping Machines – Operated by hand, ideal for small businesses, DIY projects, and leather stamping.

- Pneumatic Hot Foil Stamping Machines – Use air pressure for consistent results, suitable for mid-scale production and precision branding.

- Digital Hot Foil Stamping Machines – Feature infrared positioning and automated settings for high-end branding and custom logos.

-

Automatic Hot Stamping Machines – Fully automated for mass production, often used in packaging, book covers, and high-speed printing.

Hot Foil Stamping Materials & Temperature Guide

To achieve the best results, different materials require specific temperature settings:

- Leather: 100-130°C – Avoid excessive heat to prevent burning.

- PU (Synthetic Leather): 90-110°C – Lower temperatures prevent melting.

- Paper & Cardstock: 80-110°C – Coated paper may require slightly higher temperatures.

- Wood: 120-150°C – Hardwoods need more heat; light woods can burn easily.

- Plastic (PVC, ABS): 80-130°C – Short exposure at low temperatures ensures clean stamping.

- Fabric: 110-150°C – Special foils may be required for adhesion.

- Acrylic: 110-140°C – Overheating can cause warping.

- Glass & Metal: 200-300°C – High-temperature foils ensure proper bonding.

Best Applications for Hot Foil Stamping Machines

Hot foil stamping is widely used in industries that require premium branding and decorative effects.

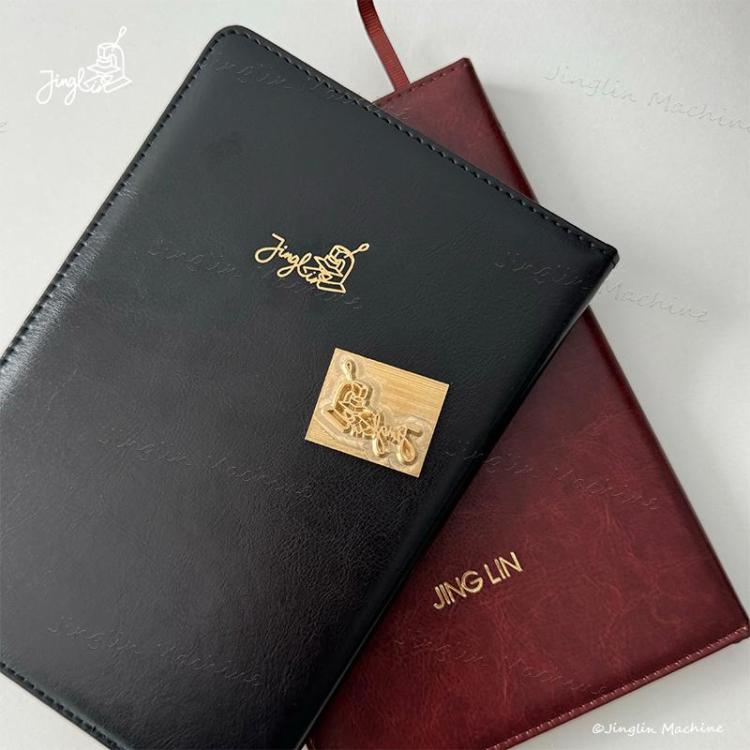

- Leather Goods – Customizing wallets, luggage tags, belts, and keychains.

- Stationery & Packaging – Enhancing business cards, gift boxes, and book covers.

- Wood & Craft Items – Branding furniture, wooden plaques, and wine boxes.

- Plastic & Acrylic Products – Stamping phone cases, hotel keycards, and cosmetic packaging.

- Glass & Metal Surfaces – Creating luxury branding on wine bottles, trophies, and premium labels.

For precise custom logo stamping on leather, a digital hot foil stamping machine with infrared positioning is the best option.

Hot Foil Stamping vs. Other Printing Techniques

Hot foil stamping offers a high-end, durable, and elegant finish compared to other printing methods:

- Hot Foil Stamping – Produces a luxurious metallic effect on various materials but requires a custom stamping die.

- Screen Printing – Good for large-scale production but lacks metallic shine and embossing effects.

- UV Printing – Provides vibrant colors and detailed prints but is less durable and lacks texture.

-

Laser Engraving – Permanent and precise but does not add color or foil effects.

How to Choose the Right Hot Foil Stamping Machine?

When selecting a hot foil stamping machine, consider the following:

- Material Type – Whether you're working with leather, paper, plastic, or metal.

- Production Volume – Whether you need a machine for small-batch customization or large-scale production.

- Precision Features – Advanced features like infrared positioning and digital temperature control improve stamping accuracy.

-

Budget Considerations – Manual machines are more affordable, while digital models offer better efficiency and customization options.

Hot Foil Stamping Industry Trends & Future Innovations

Hot foil stamping technology continues to evolve with new trends:

- Smart Foil Stamping Machines – AI-powered positioning and cloud-based control for increased automation.

- Eco-Friendly Foils – Sustainable, biodegradable foil materials to meet environmental regulations.

- Expanded Applications – New uses in fashion accessories, 3D printing, and automotive branding.

With the demand for customization, premium branding, and durable printing solutions growing, hot foil stamping remains a top choice for businesses seeking to elevate product presentation.

Conclusion

A hot foil stamping machine is a valuable tool for creating high-quality, professional, and eye-catching designs. Whether you're customizing leather goods, branding business materials, or upgrading product packaging, choosing the right machine can enhance your brand image and increase product appeal.

Looking for the best hot stamping machine for your business? Contact us today to find the perfect model!

JingLin, It Has Been Focusing on Hot Stamping Machine and Accessories

Devoted to Crafting an Impeccable Embossing Experience

WELCOME TO SHARE YOUR STAMPING DETAILS

Contact Us:

Web:www.jinglinmachine

Email:Jinglinmachine@gmail.com

Whatsapp:(+86)152 1725 7884