Option B: Universal Motor with Triac Speed Control

Option B: Universal Motor with Triac Speed Control

See the parent article: Choosing a Motor

A common type of motor for industrial sewing machines is a universal motor with triac speed control. These motors, when sold for powering an industrial sewing machines, are predominantly labeled “servo motors” because it is hip and trendy to do so. But they are distinct in operation from a true servo motor. They actually drive a lot like an older domestic sewing machine.

1. What is a Universal Motor

In a nutshell: it’s a motor that can run on AC or DC voltage, and whose speed and torque can be varied together by varying the input voltage.

See this page on wikipedia: https://en.wikipedia.org/wiki/Universal_motor

Note universal motors always have brushes. If you see someone on the forum talking about a “brushed servo motor” they are almost always talking about a universal motor with triac speed controller.

2. What is a Triac Speed Controller

See this page on wikipedia: https://en.wikipedia.org/wiki/TRIAC#Application

In a nutshell: it’s a speed controller that works in open-loop mode. Meaning there is no feedback loop. A motor driven with a triac speed controller will go faster with low load than it will with high load.

You’ve probably experienced other devices that use a triac speed controller:

- Electric drill

- Newer Domestic sewing machine (but not digital)

3. Is a Universal Motor with Triac Speed Control the right Motor for me?

The biggest difference I notice between the old school domestic sewing machine motors and this universal motor with triac speed control is the sound. And this one has more power.

Choose a Universal Motor with Triac Speed Control if:

- you want something dead simple that just works

- you don’t want to have to read any manuals

- you don’t mind the inconsistency in penetrating power based on speed

- you are happy with the feel of traditional domestic sewing machine motors & gas pedals

- you are going to be getting a speed reducer anyway. (These supposedly are easier to drive with speed reducers)

- You don’t want any surprises when you ease onto the gas pedal

- You want something forgiving

- You are NOT interested in a needle position sensor

- You do not need precision

4. Why I bought a Universal Motor with Triac Speed Control

I bought this motor to see what I was missing out on. I’ve previously been running digital servos on both of my sewing machines, geared down via undersized motor pulley to either 1.5:1 or 2.2:1 depending on the machine. But the forum topic of Development of best servo motor for leather sewing machine came up and I decided to broaden my horizons based on input from kgg and wizcrafts. I also wanted to set up my new Singer 31-15 to be tame enough that my girlfriend, long time sewer, would feel comfortable using it.

4.1 Where I bought it

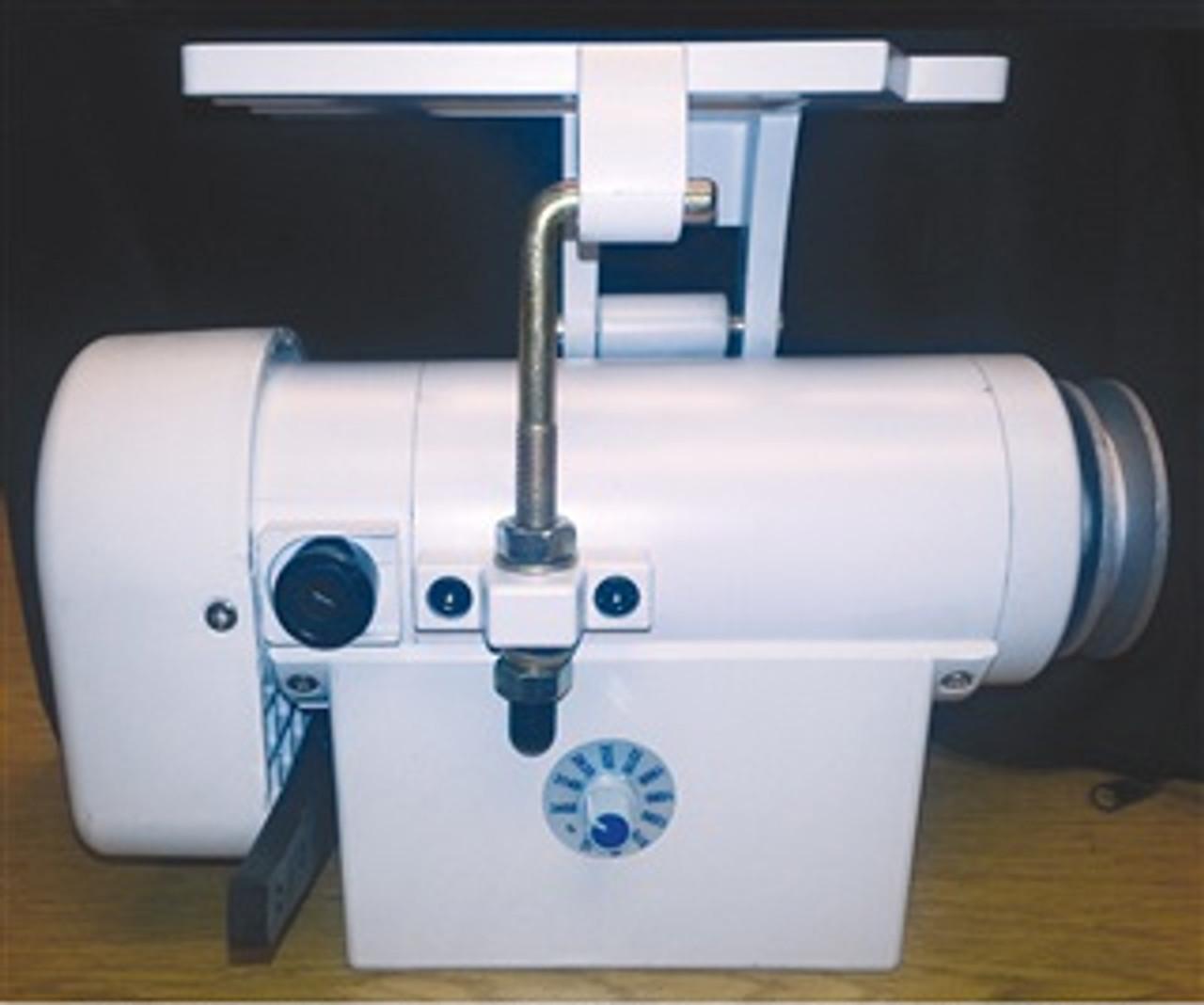

I purchased this from https://www.amazon.com/dp/B0DX28QPJS for $130. It has since gone down to $122. The brand on this one is “Smudukkit”, but the photos look identical to other motors I’ve seen at other retailers and in youtube videos. So I’m conjecturing that this model is ubiquitous.

5. Good Features

- Simple interface

- No surprises

6. Physical Brake Shoe

There is a physical brake shoe that activates any time you are not pressing on the treadle. This makes it harder to move the handwheel. You can either press just slightly on the treadle to release the brake every time you want to move the handwheel. I removed the brake shoe on mine and was much happier without it.

7. Overall Impressions

It behaves just like a traditional domestic sewing machine motor. That is, you press gently on the treadle to go slowly. But when you cross a seam at low speed, you have to press more on the treadle or the machine will stop. So you press a lot to get past the seam, and then the motor zooms ahead.

The good news is, there are few surprises with this motor. It does take some art to drive it well at low speeds, to get just enough umph on it to perforate the fabric without stalling.

8. Ideal Universal Motor with Triac Speed Control

For those whose ambition it is to build better Universal Motors with Triac Speed Control, here are several categories that could use improvement.

8.1 Make the knob turn the other way

Most electronic devices I am used to go faster when you turn the knob clockwise.

8.1 Add a switch for LOW / HIGH

To run this motor very slowly, you will find yourself at the fringes of adjustment on the potentiometer, with poor resolution.

Adding a switch for LOW/HIGH (where switching to LOW simply adds a resistor inline with the +5V terminal on the potentiometer) would provide much better resolution and repeatability for those of us who want to mainly use the slow end of this motor’s capabilities.

This might also keep us from accidentally turning the motor up too high.

8.2 Move the Controls to a Separate Pod

It’s hard to find the knob from a seated position, and I worry that I will get my fingers wrapped up in the belt when I go reaching under the table for it.

Moving the control knob(s) to a separate pod would allow the user to see the knob and to reach it safely.

8.3 Ship them with 45mm motor pulleys

This will slow down the machine without people having to buy a separate pulley.

0 Comments

Recommended Comments

There are no comments to display.

Join the conversation

You are posting as a guest. If you have an account, sign in now to post with your account.

Note: Your post will require moderator approval before it will be visible.