New Plan

So then I came up with a clasp idea. I used 12 gauge copper wire doubled up and then hammered down to a flat width of about a 1/4 inch for the through tangs. And then I got the solder procedure down for a super solid adhesion. I doubt you could twist that copper piece off of the back of that pin with a pair of channel locks. The whole deal came out super solid. The solder wicked all the way around the piece, the middle and into every micro crevice. There is absolutely no twisting of the pin on the front flap whatsoever. It fulfilled all my best hopes for the pin attachment.

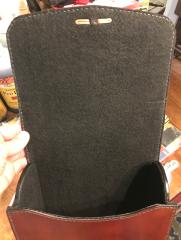

Photo Information

- Taken with Canon Canon PowerShot A620

- Focal Length 7.3 mm

- Exposure Time 1/60

- f Aperture f/2.8

Recommended Comments

There are no comments to display.

Join the conversation

You can post now and register later. If you have an account, sign in now to post with your account.

Note: Your post will require moderator approval before it will be visible.