-

Posts

46 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Calidora

-

I got it moving. Now, after I get the WD-40 off everything. What type of lube should I use for this machine. I imagine that different parts need different type of lubricant. I keep finding info saying all kinds of stuff from regular sewing machine oil to ATF even kerosene and I'm not exactly sure what info to go with. If there is a consensus on this I'd welcome the info. Thanks PXL_20251209_021619880.mp4

-

Unfortunately. I've not been able to find the parts I'm looking for. They are quite hard to find. I'm working on making them myself. For now I have been making due with manually moving the work myself without the stitch length regulator. Mine is also a Pederson 308. This and the Junker & Ruh are identical machines.

-

Custom speed reducer pulley for Singer 51W56

Calidora replied to FDC's topic in Leather Sewing Machines

Wow yours look way better than mine. They are amazing machines. Now that I have mine up and running it makes working on things much easier. I find that post beds are some of the most versatile machine out there. I don't have too much experience with several others but I've used a cylinder bed and flat and I like my post bed much better. -

Thank you. I'll just buy one I should learn how to disassemble this machine anyway.

-

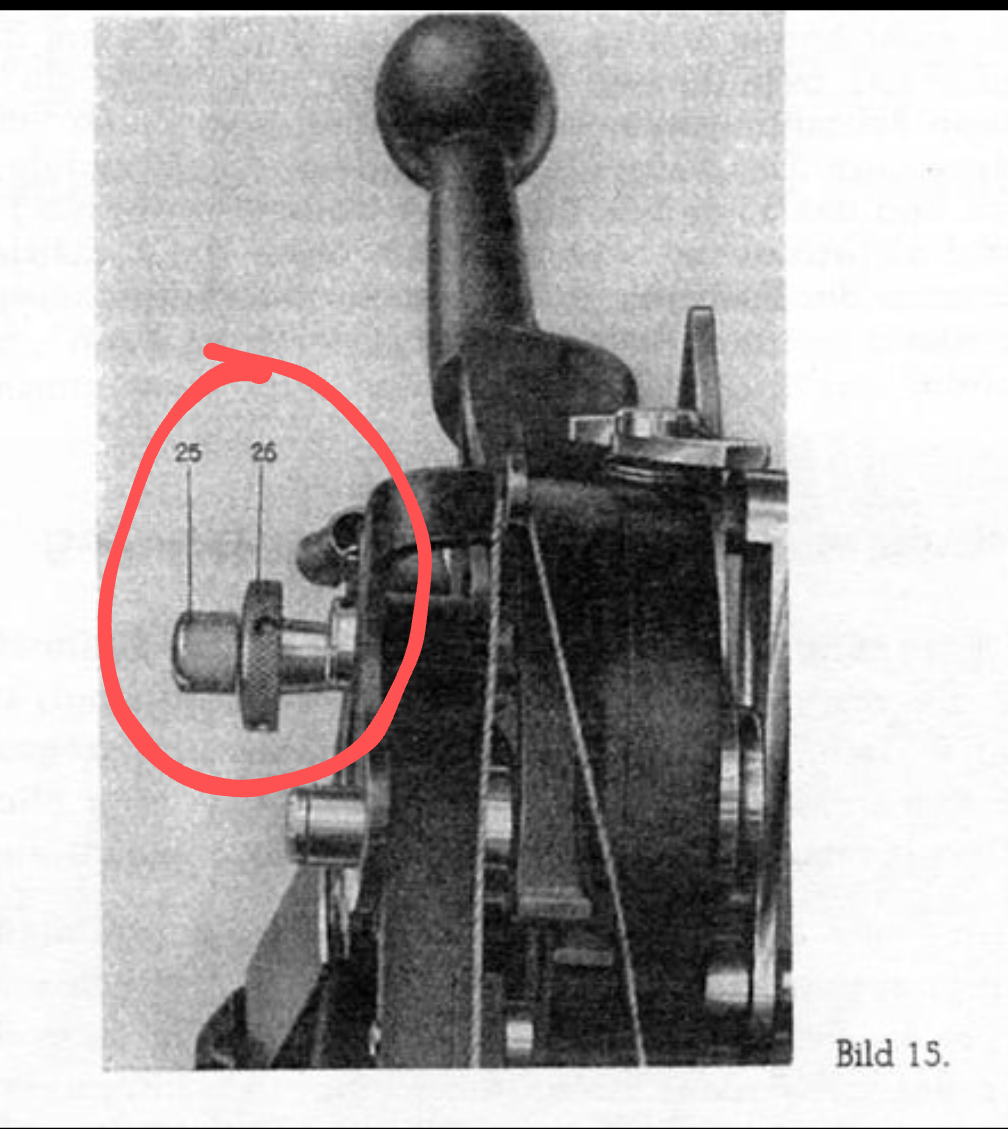

Yeah, I have a few needles. I looked through Ebay and they currently don't have the parts I need. I'm sure I can make the tensioner and the plate thing myself but the screw for the stitch length is another story. If I knew the thread pitch and size, I might be able to make one on the lathe but I'm not sure. never made a screw before. I do have a machine shop near by maybe I'll go to them if I can find the info I need. thanks for the help.

-

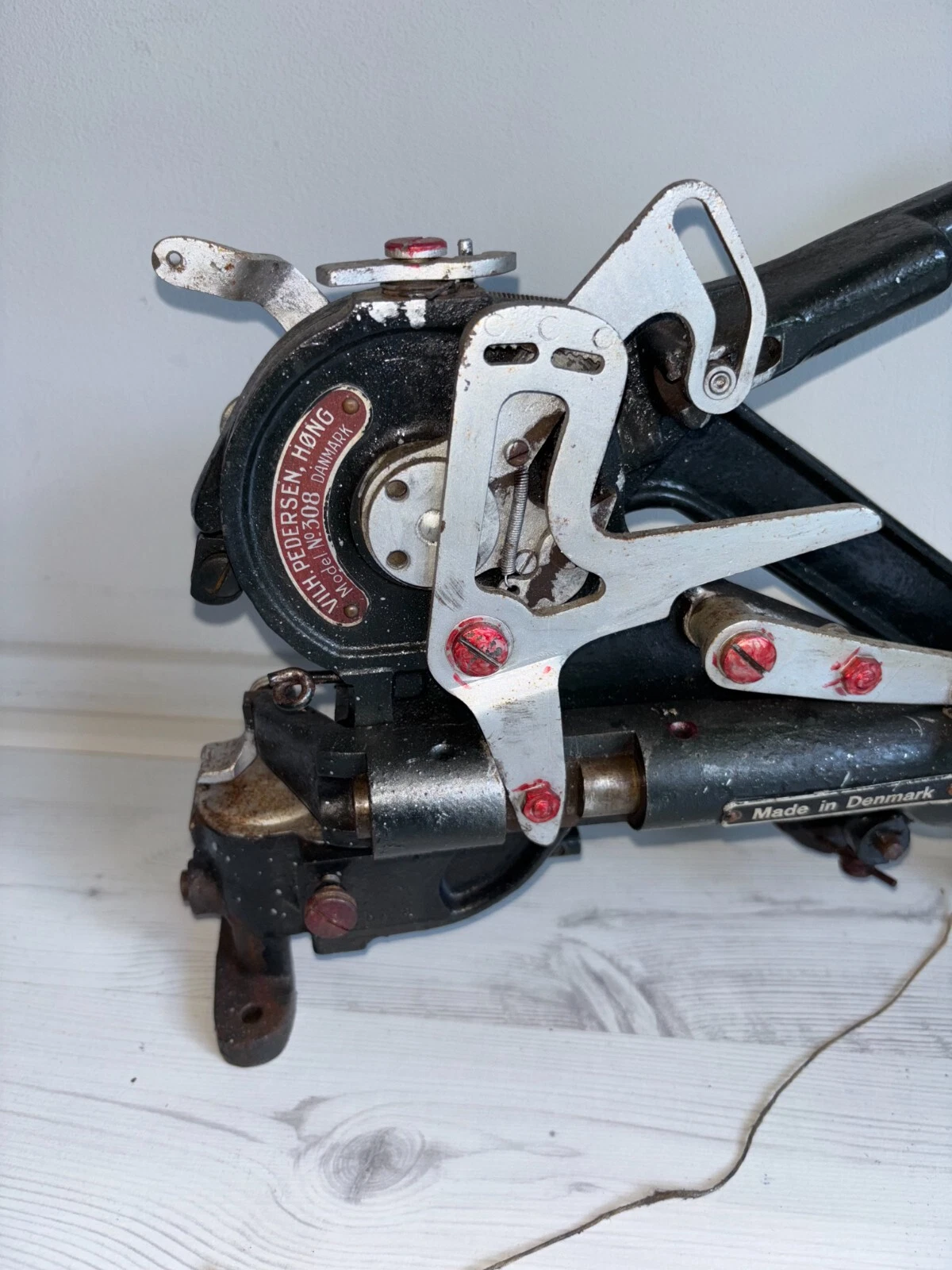

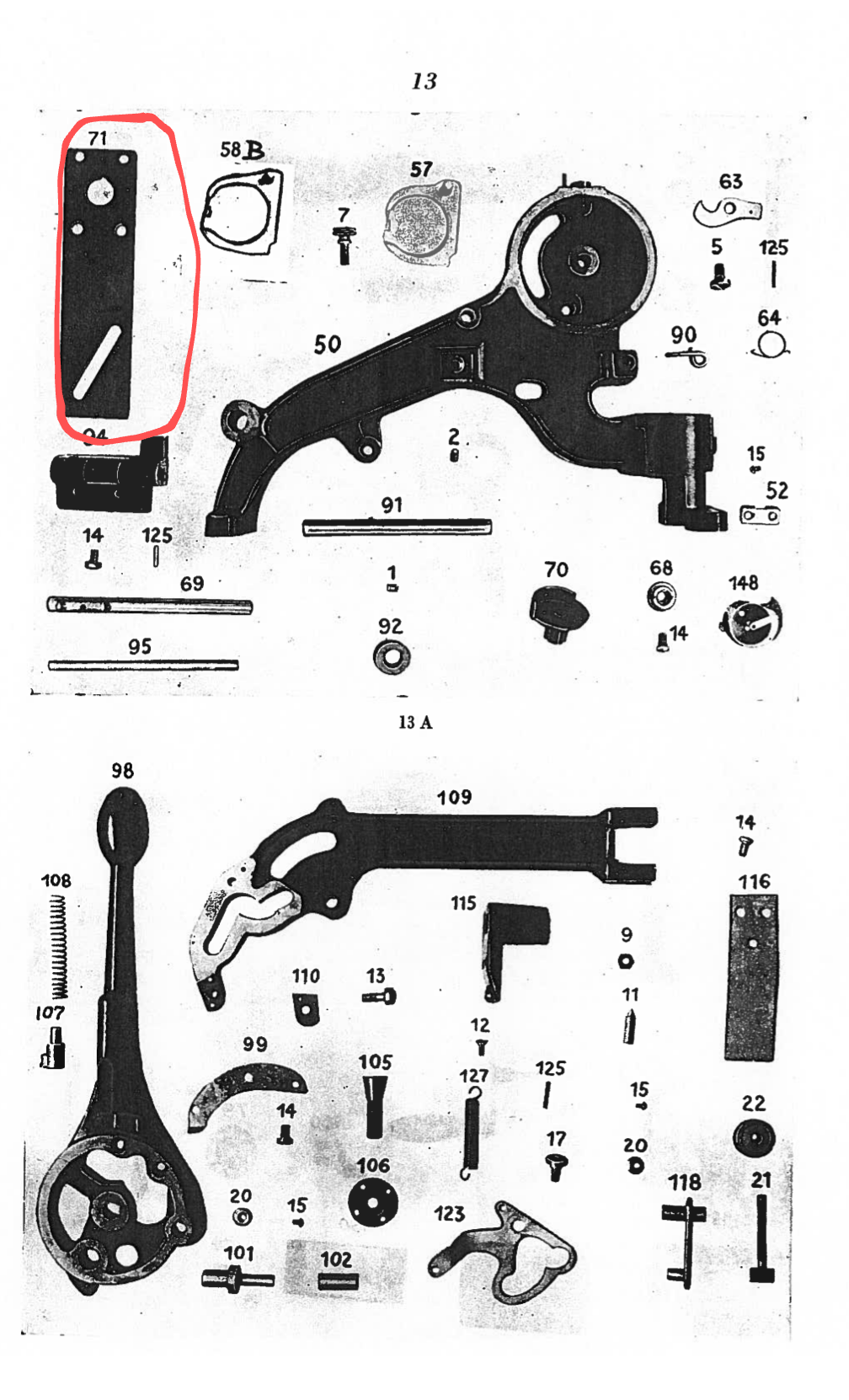

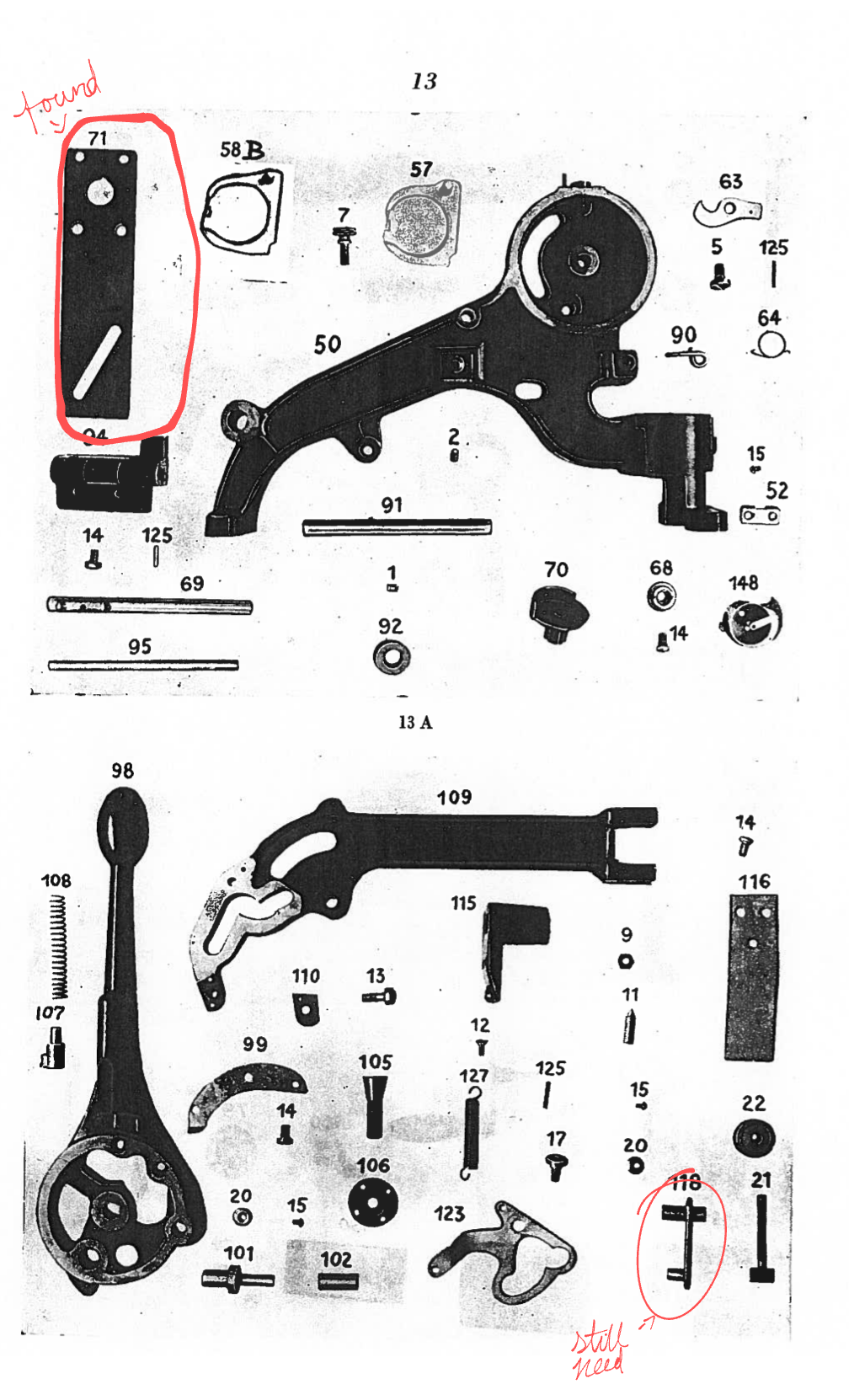

I recently purchased a Pederson model 308 and noticed that it needs some parts. It's missing the entire tensioning unit and the parts circled in the images. I believe they are interchangeable with the Junker and Ruh SD28. Is there somewhere that I might find these parts or am I out of luck and will have to make them myself. Thank you for your time

-

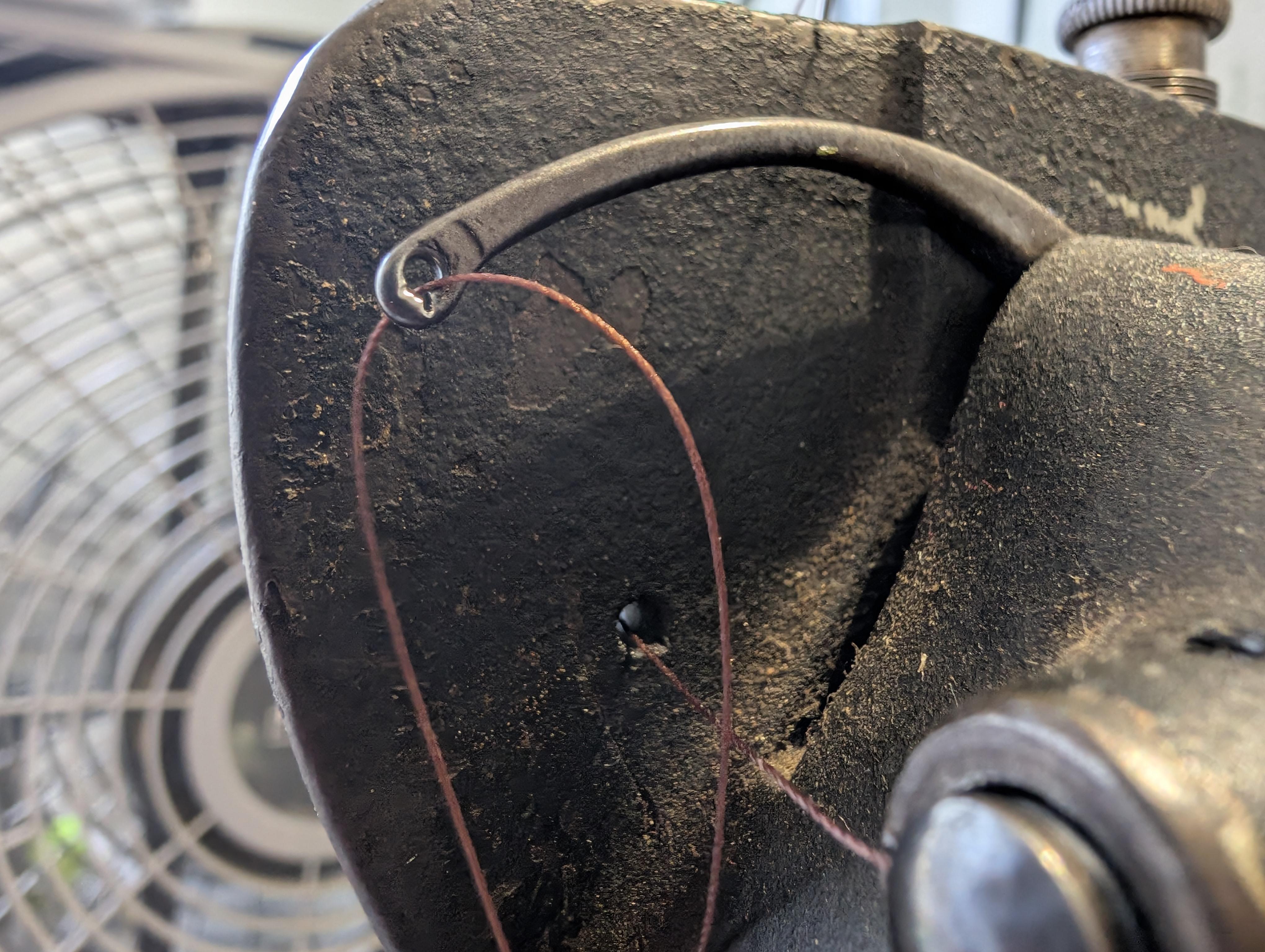

Ok. So apparently this machine has seen heavy use. The take-up lever eyelet is getting close to being cut open by the thread. Is there a way to remedy this? Other than replacing it that is.

-

One quick last thing. I got the new needle bar to make the change so I can use larger needles but I realized that the one it already has on fits the same size needle and they have the same size opening. Seems like other than the length and age the needle bars are the same. I wonder if someone had already made the change. The image shows the new needle bar I ordered and the current needle size that I'm using it fits seamlessly.

-

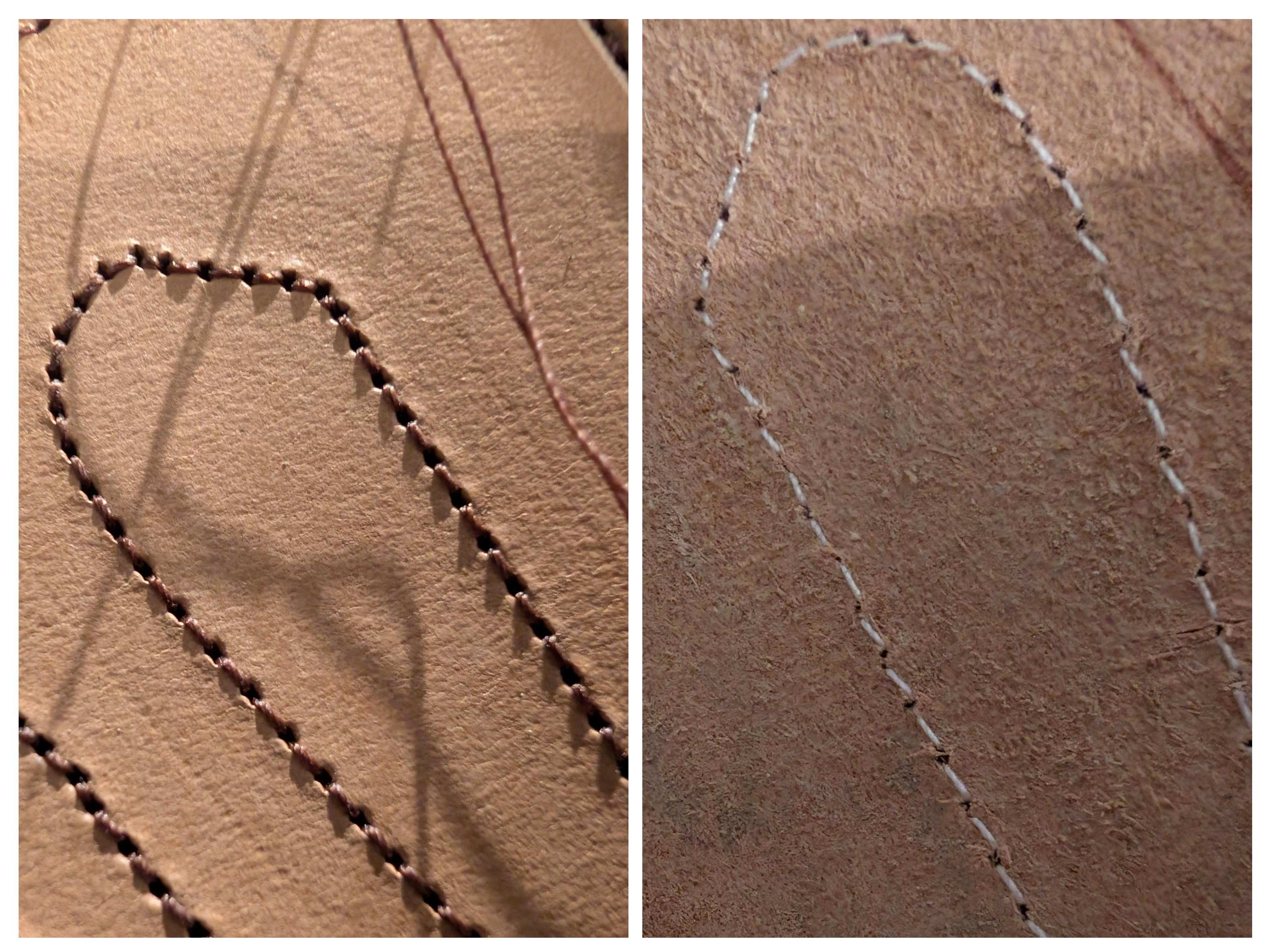

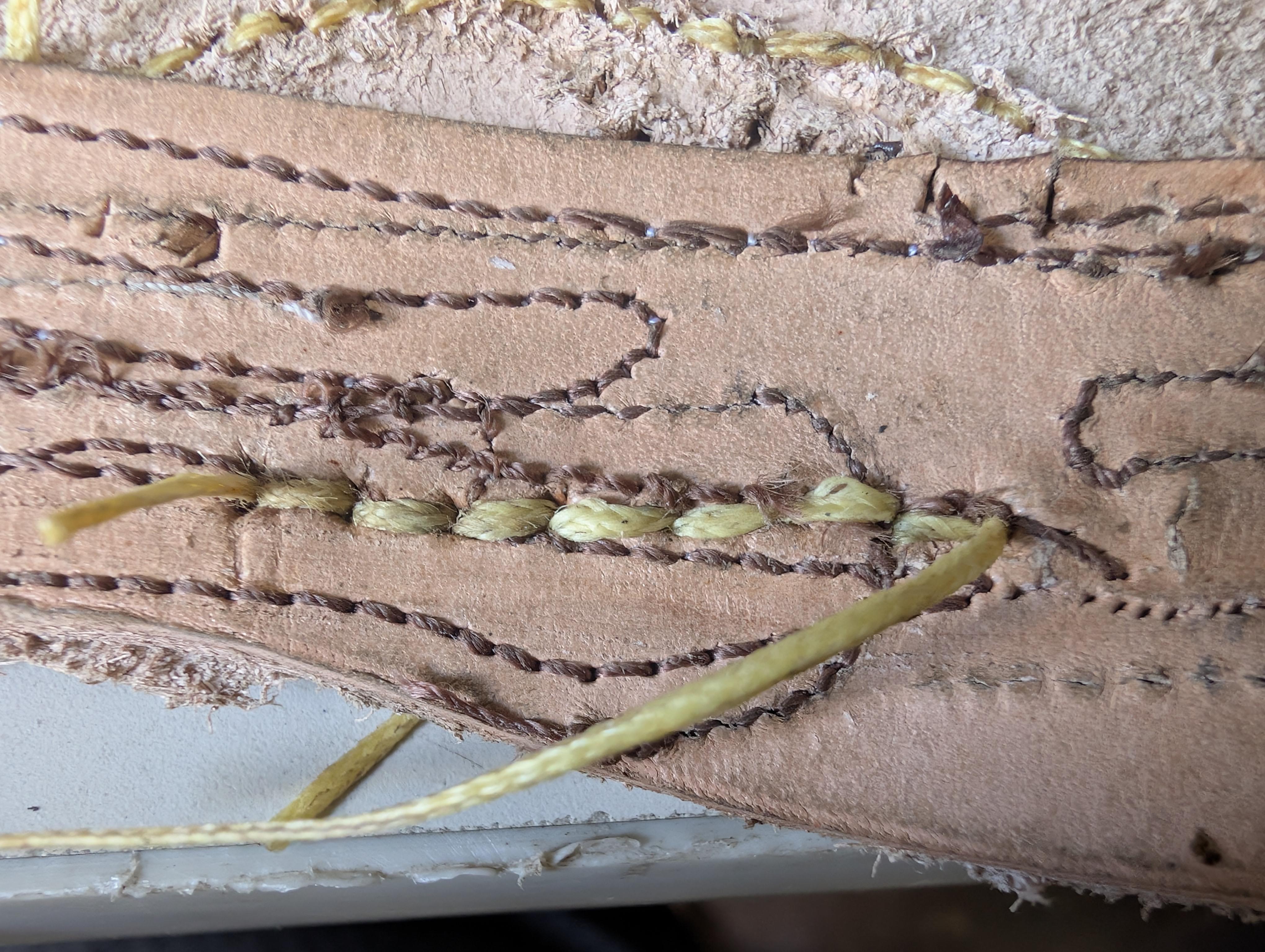

Thank you for all the information and help. This is how it's currently sewing. The white thread is thinner than the brown but it's the only other thread that was a contrasting color to see if my tension was right.

-

-

Ok cool Makes sense. When I get home from work I'll do that.

-

-

Interesting. I thought I installed it correctly but I'll be the first to admit that I don't know that much about these machines. When you have time let me know how it should be. Thank you.

-

Yes. I added that. On the manual it showed that it has a pin there but it was missing so I put a bent needle in the hole. It seems to sew better with it than without although now that you mention that it's not going through the spring that might be why.

-

.webp.4d7785cc054b1306bd20880d2db0a74f.webp)

.webp.b95d0633375da6bddcfbcefd1ad1da3c.webp)

.webp.051589581b2f950c1958c87c114f2d5a.webp)

.webp.caea44d68c216fef4dbdf65561598be6.webp)

.webp.3431bbd6928190ddec16d972e97c1063.webp)

.webp.f27d31de04a1c4f15e8ac13939d0925d.webp)

.webp.75e6e77fe7a48e5f9253494467eee692.webp)

.webp.8b5cc0c9d6bd30ad96cb8fb1f927cc7f.webp)

.webp.81b187ea43bf315bb46c21f53360c48e.webp)

.webp.d299762019f966b0d27f98f80bd131e8.webp)

.webp.1ff2138da00e7c11b81bc98baca9863b.webp)

.webp.590d295836f0a25741f01fd8df1f5b9e.webp)