matthew123

Members-

Posts

9 -

Joined

-

Last visited

Profile Information

-

Location

nyc

-

Interests

bags, outerwear, sewing machines

LW Info

-

Interested in learning about

bags, clothes, leather, canvas, upholstery

-

How did you find leatherworker.net?

reading about sewing machines

matthew123's Achievements

New Member (1/4)

-

Help! Singer 111w155 stripped / stuck screw

matthew123 replied to matthew123's topic in Leather Sewing Machines

Awesome, thank you. I'll see about getting a replacement. Thanks again for all your help; I really appreciate it. -

Help! Singer 111w155 stripped / stuck screw

matthew123 replied to matthew123's topic in Leather Sewing Machines

Thanks Friquant! You are totally right...I am missing that lock nut and that screw and I didn't realize it. Uh oh. Any idea what that screw does? -

Help! Singer 111w155 stripped / stuck screw

matthew123 replied to matthew123's topic in Leather Sewing Machines

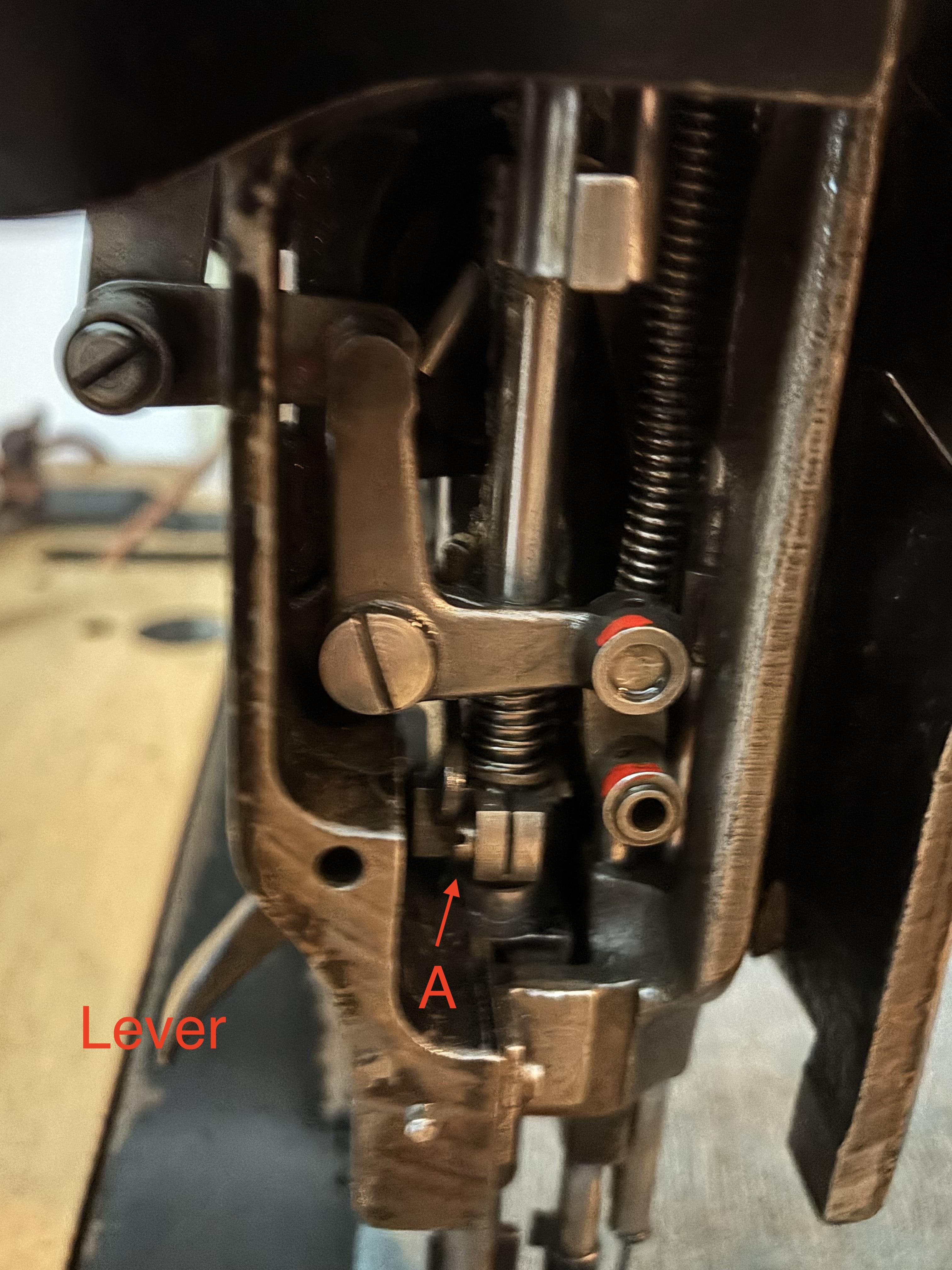

Thank you all for your help! I ended up cheating a little bit and took the machine to a machine shop. The machinist got the screw out in minutes and didn't charge me. I asked him how he did it, and he said I had already done all the work for him 😆 I think it was likely a case of having the right selection of screwdrivers to fit the deformed slot, just like you all advised me. He also is 94 years old and probably has about 85 years of experience. What a legend! Since he didn't need to drill the screw, I still have it. I cut a new slot in the head perpendicular to the old one, cleaned the threads on the screw and on the machine side, and so far I'm reusing the screw and it seems to be fine. I got the feet lifting equally now, too. The only things that seem wrong still are: 1. Cranking the machine takes a bit more effort during the part of the cycle when the inner foot is making contact with the work and the needle is down. I don't see anything binding, it just doesn't feel as loose and smooth as the part of the cycle when the needle is up. Is that normal? 2. The pressure foot lift releasing lever (the lever you'd use to raise the feet when beginning and ending your stitch) will lift the feet when the needle is up (and the outside feet are down) but won't lift the feet when the needle is in the work and the inner foot is down. Any ideas? I think it's something with either screw A or screw B in the pics I've attached. The lifting lever isn't contacting the whole assembly it needs to lift when the needle is in the down position. THANK YOU all again for your advice and guidance. You guys rock!! -

Help! Singer 111w155 stripped / stuck screw

matthew123 replied to matthew123's topic in Leather Sewing Machines

Thank you dikman! That is the type of torch I have, so I will keep at it. Thanks Doogmiester! Do you think it's a standard thread pitch and size? I've heard Singer screws are all different types of thread arrangements. Any suggestions where to buy a new screw? Thanks Friquant! I will fine tune it that way and get them equal. Alzilla, I agree it may come down to drilling.... Will keep y'all posted when I have some time to tackle it this weekend. Thanks again!!! -

Help! Singer 111w155 stripped / stuck screw

matthew123 replied to matthew123's topic in Leather Sewing Machines

Yes, the inner is definitely still lifting higher than the outer, but they're closer to equal than before, and both are lifting higher overall than they were before. The outer used to do almost nothing. -

Help! Singer 111w155 stripped / stuck screw

matthew123 replied to matthew123's topic in Leather Sewing Machines

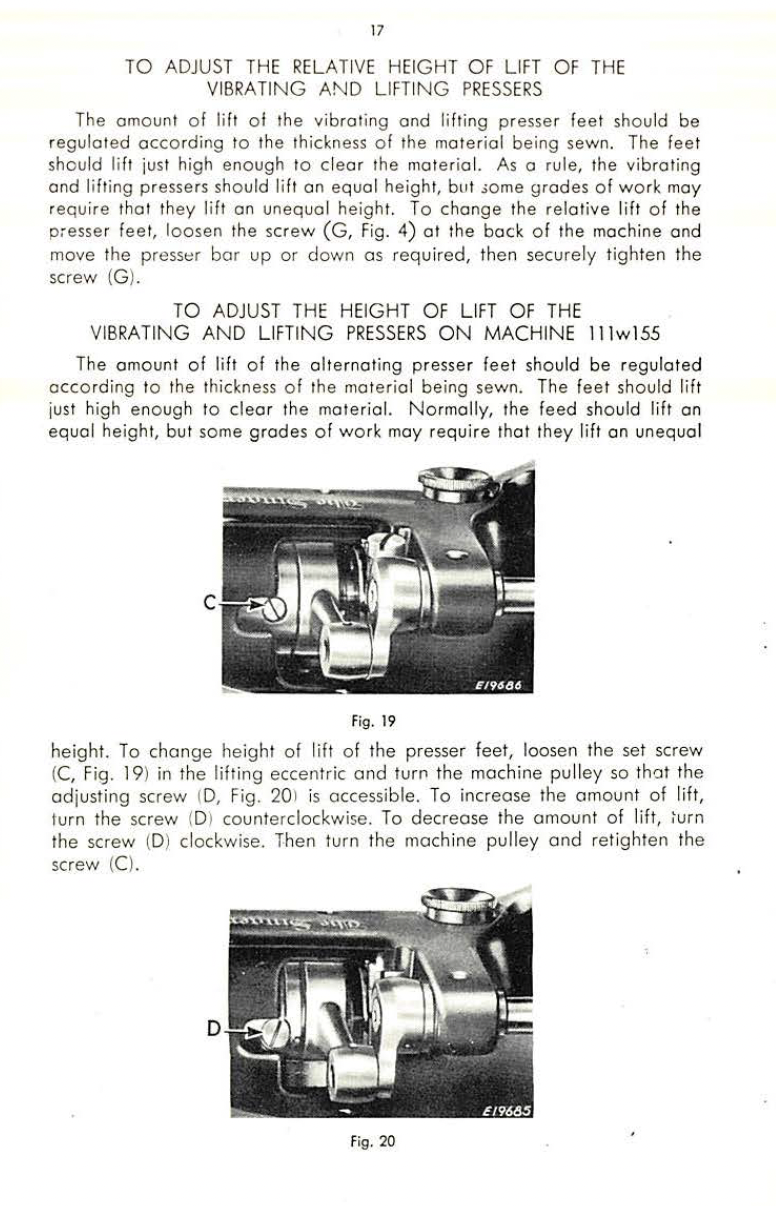

Thank you again everyone! I will respond in more depth soon. Just wanted to share an exciting update. I haven't worked on the stripped screw at all. However, I noticed that now the worm screw "D" turns with some resistance and actually changes the height that the presser feet lift. So I guess all the PB blaster freed something up in the eccentric mechanism? Even though I can't loosen the set screw "C", the worm screw "D" is moving the eccentric. So I was able to use the wisdom in another post combined with turning the worm screw "D" to get it walking high and looking good to me. I've attached a video of it walking now. Does it look right to you all? So I still need to address the stripped screw, but at least I know the machine is usable and adjustable and works right. Will report back when I have time to work on the screw again. Walking111.mov -

Help! Singer 111w155 stripped / stuck screw

matthew123 replied to matthew123's topic in Leather Sewing Machines

You guys rock! Thank you so much for all the amazing advice. Friquant, thanks for the heads up about adjusting that clamp screw in back. I did try that one first, but I ended up with the machine binding before I could get enough lift out of it, so I figured the next step was the stripped screw "C" in question for the eccentric. Great point about extending the filing to the edges of the screw...I think that should help a lot. I will try a flat sided carbide burr! I posted a pic of the screwdriver in the screw groove. As you can see, it's not quite tall enough and definitely not thick enough. I will either search for one or work on filing down a piece of metal to serve as the new driver. Dikman, I love the idea of drilling out the center of the screw with a small bit but still keeping the flathead groove on and use that to loosen it. I never thought of "coring" out the inside of the screw to relieve the pressure like that, but it totally makes sense and sounds like it will work! I think laying the machine down on its front is a great idea and will be very helpful. Alzilla and Friquant, do you think the impact driver is too much force against the shaft that this all rests on? I have one of those things but hesitated to use it. Thank you all again!! -

Help! Singer 111w155 stripped / stuck screw

matthew123 replied to matthew123's topic in Leather Sewing Machines

Thanks Constabulary! I agree that the screw extractor could work. I'm trying to postpone that option because I feel like maybe deepening the screwdriver groove might still be a viable option, but I admit it's hard to get the contour good enough that a screwdriver will really bite. I appreciate the suggestion! Anyone know if replacements for this screw are available? I'm open to any and all ideas! Thanks again -

Hi All! First I just want to say how grateful I am for this forum. I've learned so much from you all. Thank you for sharing your knowledge and expertise! I just picked up my first compound feed machine, a Singer 111w155. It sews OK, but the outer presser feet don't lift up enough to accommodate thick material. Based on the manual (see pic attached), it seems that to adjust the relative height of the outer foot with respect to the inner (needle) foot, one has to use the lifting eccentric. However the set screw is stripped and very stuck. See the pic attached. I believe the stripped screw is "C" in the manual screenshot. I also noticed that screw "D" (which I think is the one people call the worm screw) spins freely, which seems weird. It appears someone may have ground away part of the machine casing to get better access to this screw in the past...can anyone confirm from the pic? So far I have tried: spraying the screw with PB blaster nightly for a few nights using a Dremel with a small pineapple burr to deepen the flathead groove gently tapping the screw with a screwdriver and hammer heating it lightly with a mini butane torch I got the screwdriver to bite better when I drilled out the groove, but when I applied force, it again started widening the screw groove again and eating away at the screw head. Can anyone offer other suggestions? I am considering taking it to a local machine shop to see if they can rescue me. I am hesitant to try a left hand drill bit and screw extractor, because the option of deepening the flathead groove further with the dremel seems like a good one and I don't want to burn that bridge. Help!! Am I missing something? Thanks! Matt

.jpg.bf9bf0db77a102498b1ad5632295ab7e.jpg)