eLeM

Members-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by eLeM

-

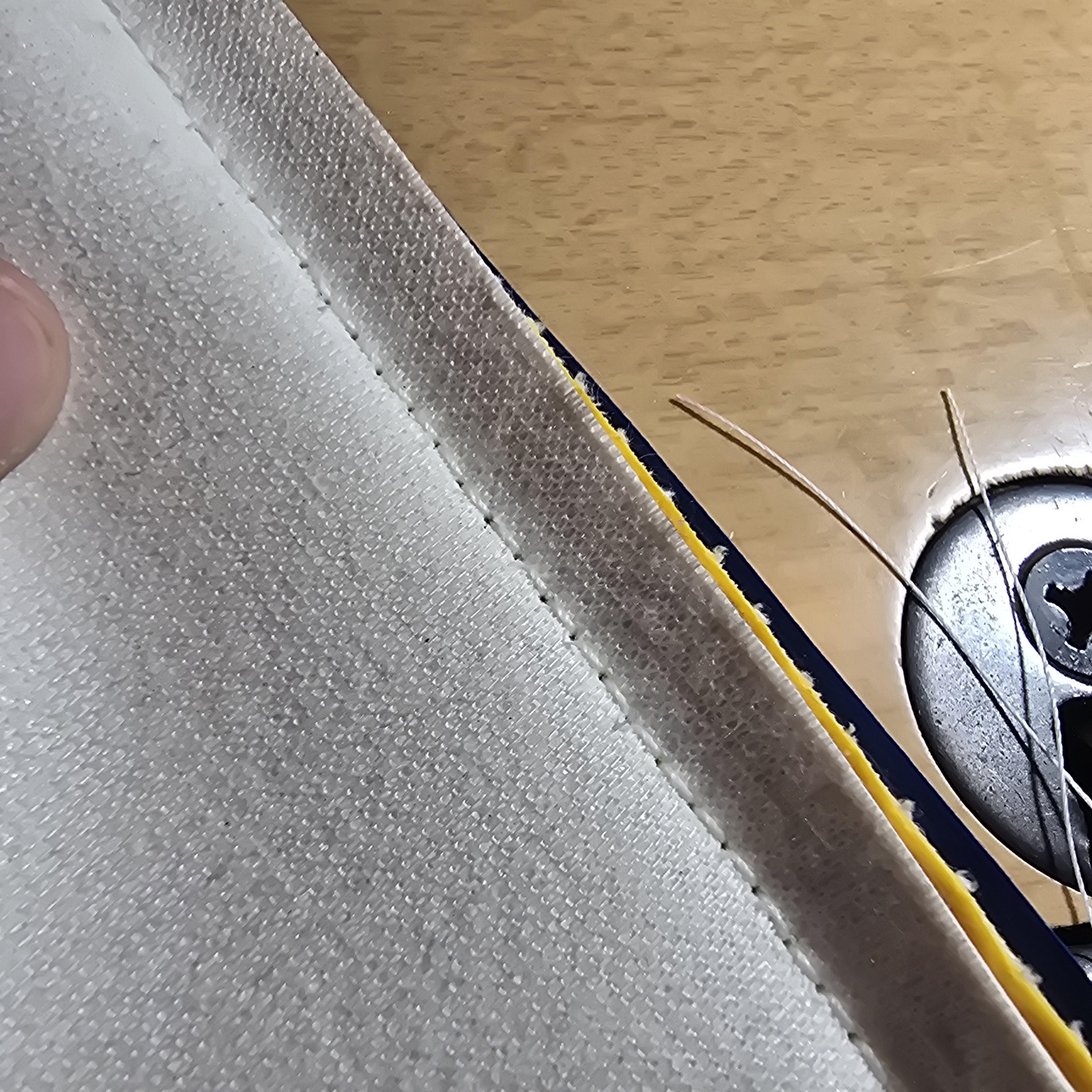

Ok, so I decided the risk wasn't worth the hassle to try and install the needle positioner at this time, but it's a project I might take on after I finish these dang ol' boat seats that I've had on my bench for far too long. But I tell you what, after cleaning this machine up, swapping the motor, getting a smaller pulley wheel and a new belt, and oiling every moving part I could find...this machine PURRS. I'm in love! And I feel so proud of what I accomplished with $200 and curiosity. This was my first line of test stitching! Thank you all so much for your help along the way, I really could not have done it without your expert guidance.

-

It does indeed have these parts (and more!) But I can't seem to figure out what tool I need to get the hand wheel screw off.

-

This came with the servo, a needle positioned right? The hole on it and the nub on the hand wheel seem like they're the same size but it doesn't seem to want to go on. Am I missing something?

-

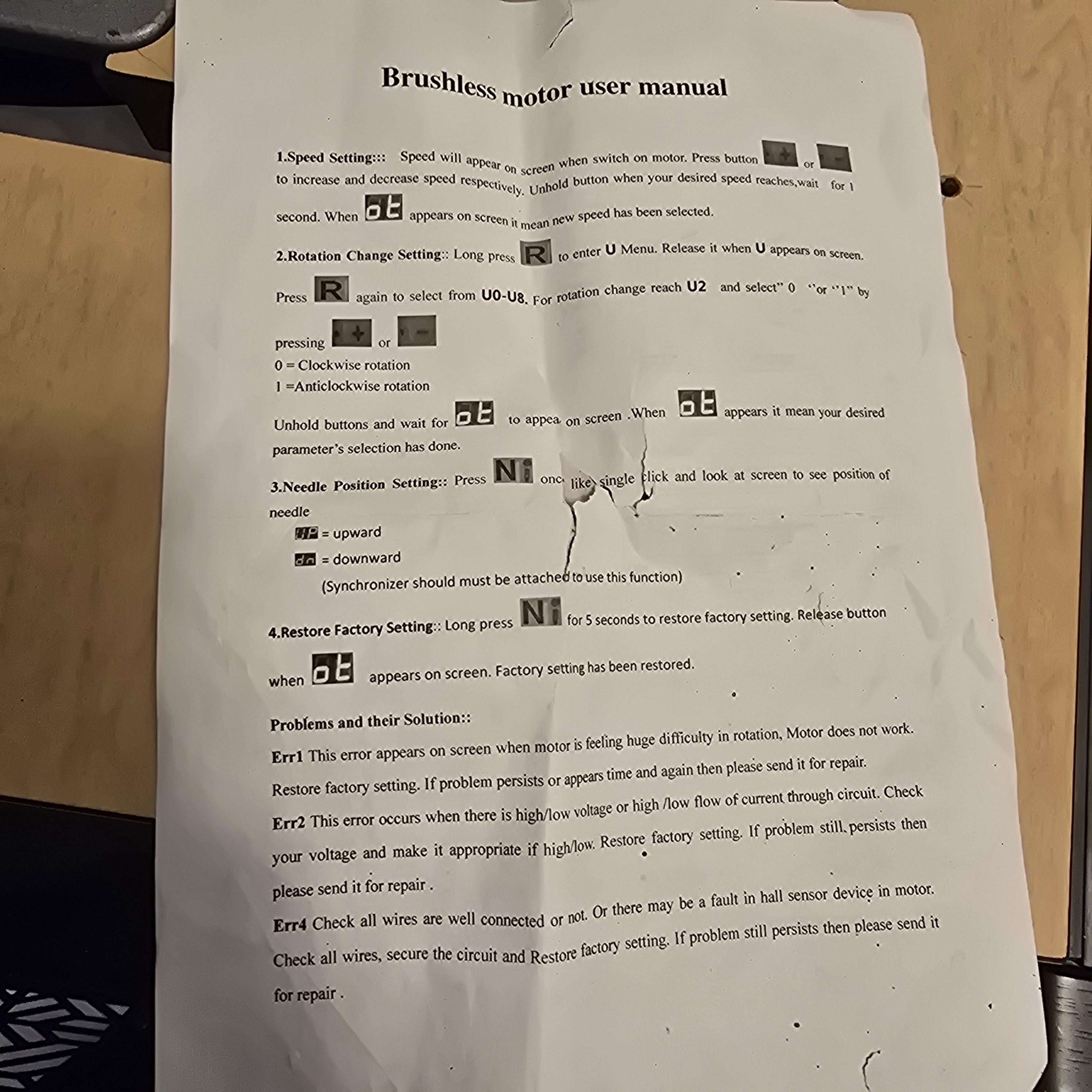

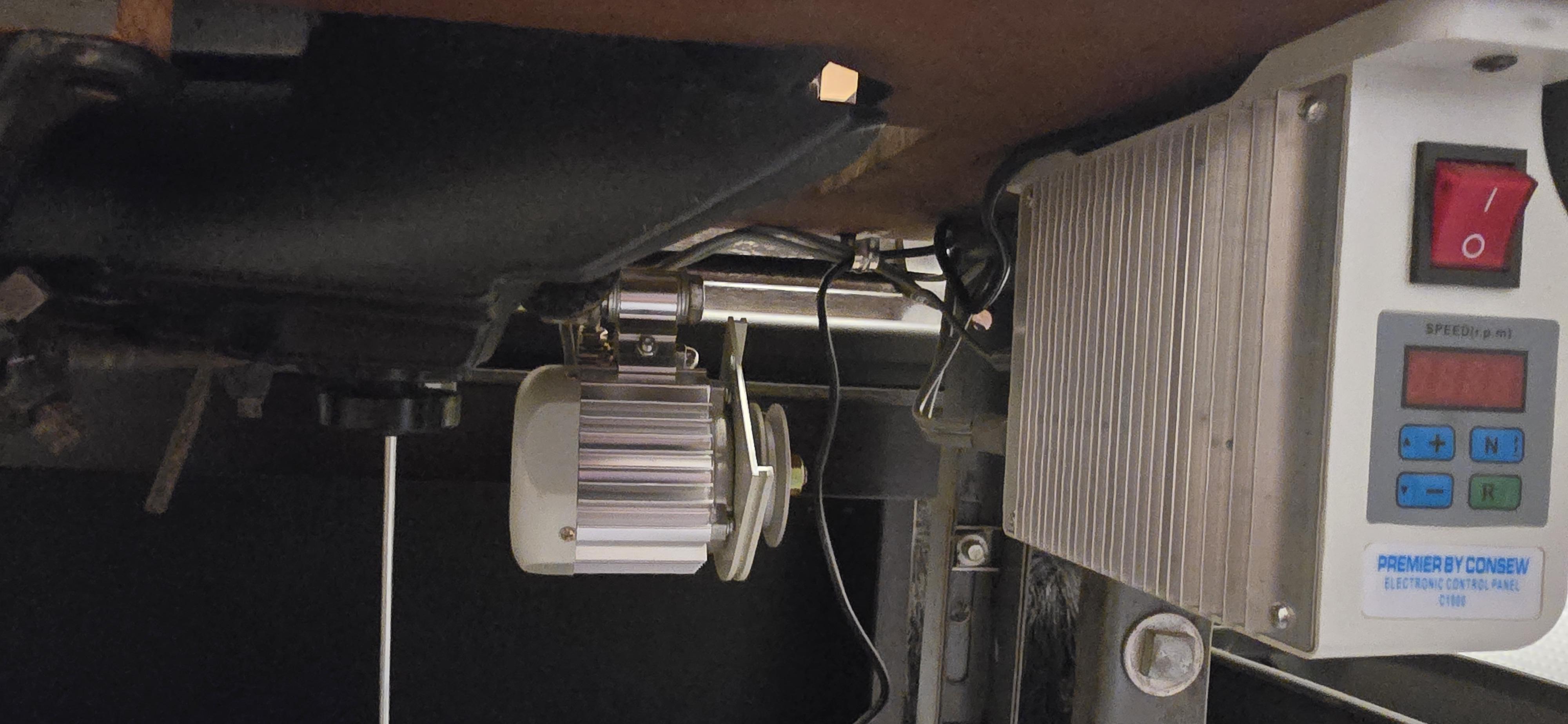

It has a chain to a knee lift, pretty cool. I attached the single document that came with the servo. I'll look into the pulley, thanks!

-

The guy I bought this from seemed to think it had reverse, but I was pretty sure these didn't have that. He works as an upholsterer but hasn't used the machine in a while, so I wonder about that. I'm happy to do the poor man's reverse for now, as my projects are not my main income and are sporadic at best. Half the joy of this machine for me is the machine itself and《tinkering》:)

-

I just wanted to thank everyone that responded to my other post looking for help picking a machine. Without your advice, I might have ended up with a much more expensive machine and disappointment. Instead, I spent $200 and a several hours cleaning and swapping out the motor on this beautiful Singer 211g165. I got the servo for free from a friend that had it lying around collecting dust, so I got a great deal on that! Anyway, allow me to show off DeVille #9 (the factory it once lived in, and the number on the table). If anyone has stories to tell of theirs, helpful info and links, etc. please share!

-

Most of them are clutch motors, but I already have a servo I can swap in.

-

I did manage to find a Consew CP206RL locally, and it's owned by a person in acquaintances with. She let me try it out, but I had problems getting the stitch length longer and had issues with the needle thread breaking no matter how I set the tension. I assume that if I could fix these issues that it would be a good enough machine, especially since it's local and only $500. She might even give me a discount for the issues we had with it.

-

They have a video on the listing of it starting up (some noise that goes away happens) and running without fabric or thread. So it does at least function in those ways. And I do love fixing things, which is why I'm kinda drawn to these older all metal machines. If I could find one with good documentation and parts availability, I'd be happy as a clam.

-

Thanks for gently keeping me from the edge. This certainly is making me crazy. I'm really only steering towards flatbed because of budget reasons. That one Singer came up because it's in the range I'm able to spend right now. And for my most pressing concern being the boat seats, the cylinder arm isn't really necessary. I think I'm trying to just maximize my spend since both space and money are restrictive for getting endless machines. It also seems that to get any machine at all, I'm going to need to drive an hour and a hall or more in almost any direction. I'm getting worn down by the idea of so much travel to see machines that maybe need work or won't actually do my boat seats. Additionally, there is no one nearby that works on industrial machines. I did find a guy that's willing to travel to me, but I don't know anything of his reputation. All that is to say that if something on the list looks more reliable than the next, I'd like to just go that direction. I looked for the other models recommended, but came up short (presumably I live in a machine void, which is odd since there are so many creative people here) and time is running out to finish my project. I think I'm just afraid to make the wrong choice. If anything happens with whichever machine I choose, I'm likely going to have to learn to repair it myself, so good documentation and parts availability would be helpful. And you can bet I'll come back here for advice on that. Thanks to everyone for your help!

-

I found a couple machines on marketplace that weren't mentioned in this thread, but seem like they'll work. Thoughts on these? Singer 211g-155 for $200, looks to be on good shape in the pictures Singer 211g165 for $700 Cutline C225 for $350 Singer 153K103 cylinder bed for $1000 And then these various Consew 206RB's: Consew 206RB-1 for $1250 Consew 206RB-2 for $750 Consew 206RB-5 for $1195 Sorry for the continuous questions!

-

Cat picture purely out of curiosity if it will post a photo direct from camera since links and direct from Google Drive won't.

-

It also seems to only allow me to take a picture directly from the camera, add from my Google drive, or link to an image. The link box doesn't tell me what the error is, it just turns red.

-

I'm using Chrome on my Galaxy S24.

-

Unknown server error. Error code -200

-

While not specifically for leather, I fell in love with this machine when I got to use it at a friend's shop years ago and stupidly forgot to get a good pic of the model number. It's a double needle walking foot and his had a folder attachment. I made the big dome cover with it, basically a flat felled seam but all in one pass. It's a Juki, and it was green, but that's all I've got. Again, the photo won't attach either as an attachment or as a link. It's only 153kb.

-

Thank you so much for this very thorough list!

-

The leg bags are simple. Phone slot, slots for pens and a flashlight, etc. All straight seams. A part cylinder with a flat bed attachment is worth looking into though, in case I end up making these bags more complex. Are there models that compare to the flatbed machines I mentioned that I should look at? Thanks!

-

It just asked me for a link to the images online, not to actually attach anything. Maybe it wouldn't allow them either way because I was still waiting for approval to join?

-

Hi all, First time poster, but have lurked quite a bit. As I suspect you've encountered countless times before, I'm looking for a machine recommendation. I'm wanting a walking foot with a servo that can do thick marine vinyl for boat seats and leather for leg bags. I'm using a size 20 needle, #92 thread for the boat upholstery, and while my current machine technically WILL do it, it's definitely the wrong machine for the job. Trying not to spend huge money (I know, laugh). I've looked at machines and specs until my eyes bleed and I'm no closer to a decision. Models I've looked at are Juki DNU-1541s, Consew 206RB, and others. Seems like these are both highly regarded. I've used a Juki LU-1508 to sew custom printed billboard vinyl to make a 2 part cover for a 40' geodesic dome, and it seems that might work for my current stuff too? Anyway, I'm overwhelmed. P.S. I have photos to help illustrate, but it's not letting me insert them.