-

Posts

28 -

Joined

-

Last visited

Profile Information

-

Location

netherlands

-

Interests

vintage bikes and cars and upholstery. vintage machines.

LW Info

-

Leatherwork Specialty

carupholstery

-

Interested in learning about

vintage machines

-

How did you find leatherworker.net?

google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

VinnyK's Achievements

Member (2/4)

-

yeah true. i was looking for some funtional options to slow down and get more control. i hope to have it functional for now and when some money comes in i might go for a chinese servo motor and upgrade this machine a bit more

-

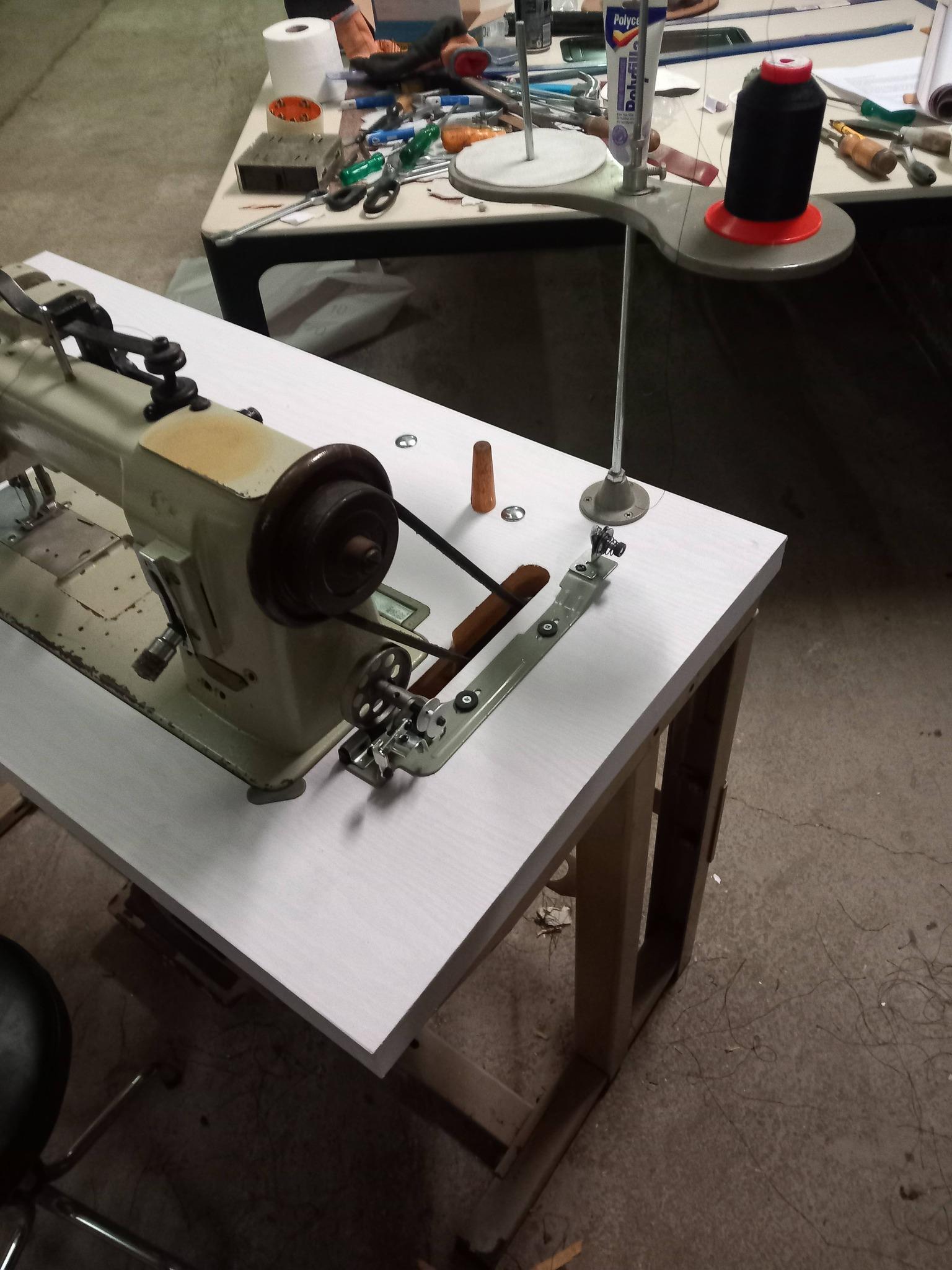

my small pulley came in so had to install it to slow the motor down a big chunk. only the shaft was conical and the new pulley wasnt. so i made counter conical filler pieces if that makes sense 😆 so the pulley cant woble and is stable on the shaft. i could not find a smaller belt in a hurry so i adjusted the motor and its tight and happy. but i wil look for a smaller one. took apart the motor to check for problems or mouse nests. but it look like new in there. just cleaned out the dust and spiderwebs a bit. the foot pedal is soo sensitive only have a tiny window to slip the clutch and keep it under control. so i made a limiter on the pedal itself for now. i call it a bumpstop speed controller 😇 im also gonna extend the arm of the motor and change the attachment to the footpedal to the left so it gets a longer stroke and more control i hope. but for now it functions as is time for it to earn some money and then upgrade again maybe even to a servo motor

-

with a functional machine its time for cosmetics. first took of the old top. i ordered some cheap and thin laminate sticker stuff. hard to get anthing wider then 55cm but i found some. im not happy with it. but its smooth waterproof and functional so ill keep it for now. as its cheaper to buy a new bobbinwinder then to restore the old one i went the speedy way put the thread stand back on it. and put it back together and its looking pretty good after that i had some time to kill so cleaned up the new workshop area and ready for some projects.

-

yeah for sure. its basicly very simple of you know all the functions and tricks to these machines. i am technically inclined build cars and bikes no worries. but these machines are a different breed of logic 😆 but i love to tinker and im glad its functional again

-

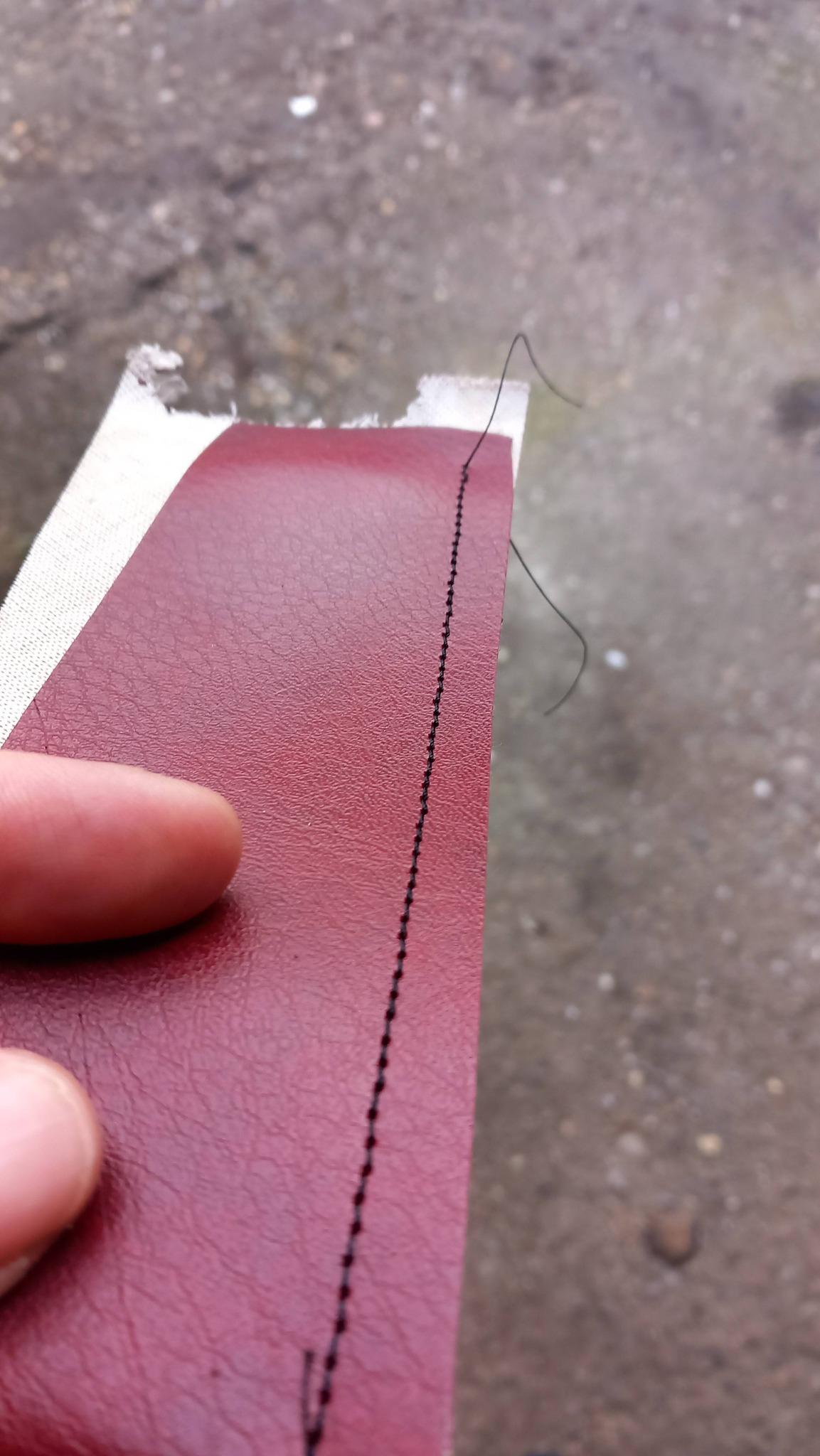

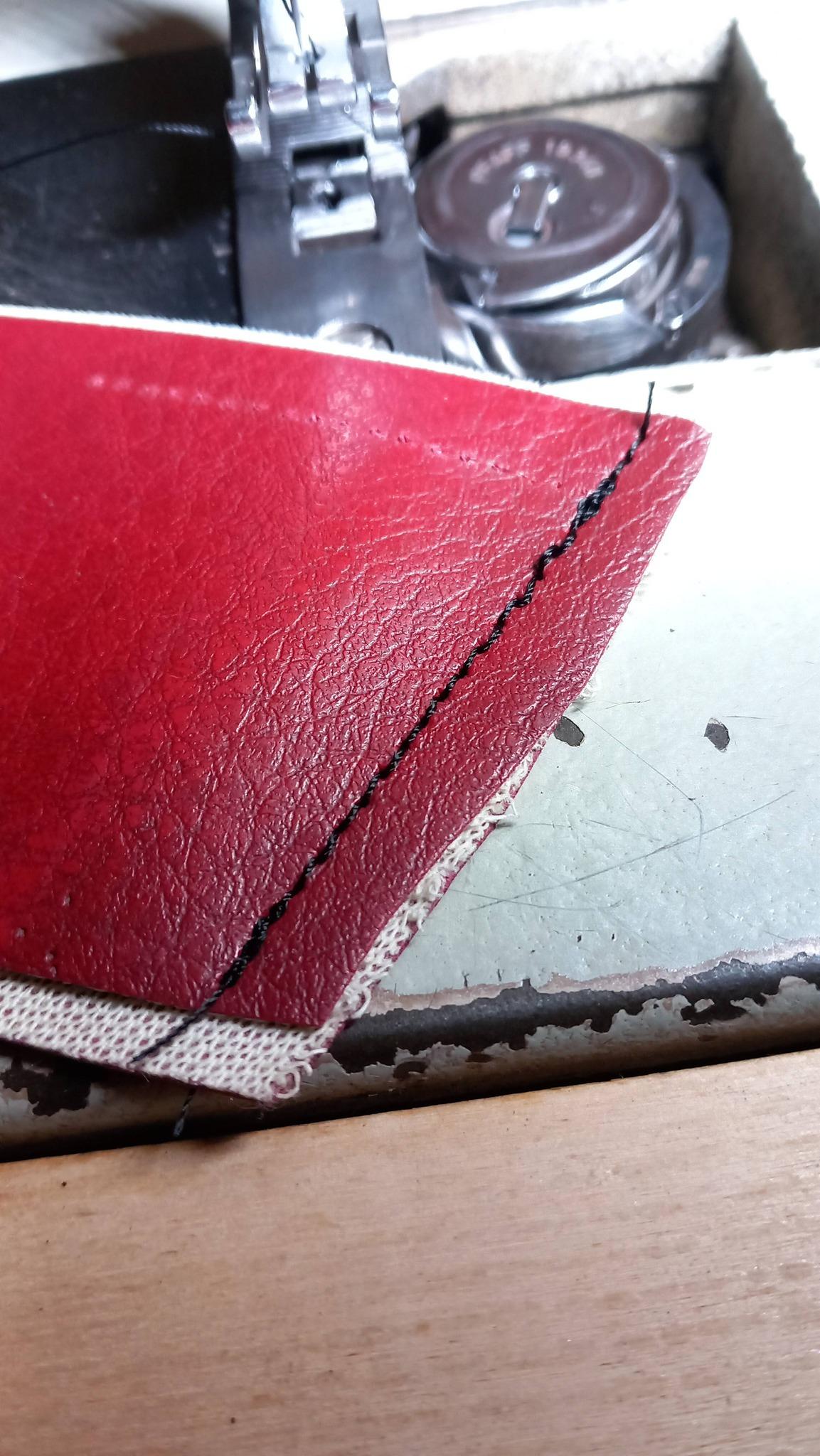

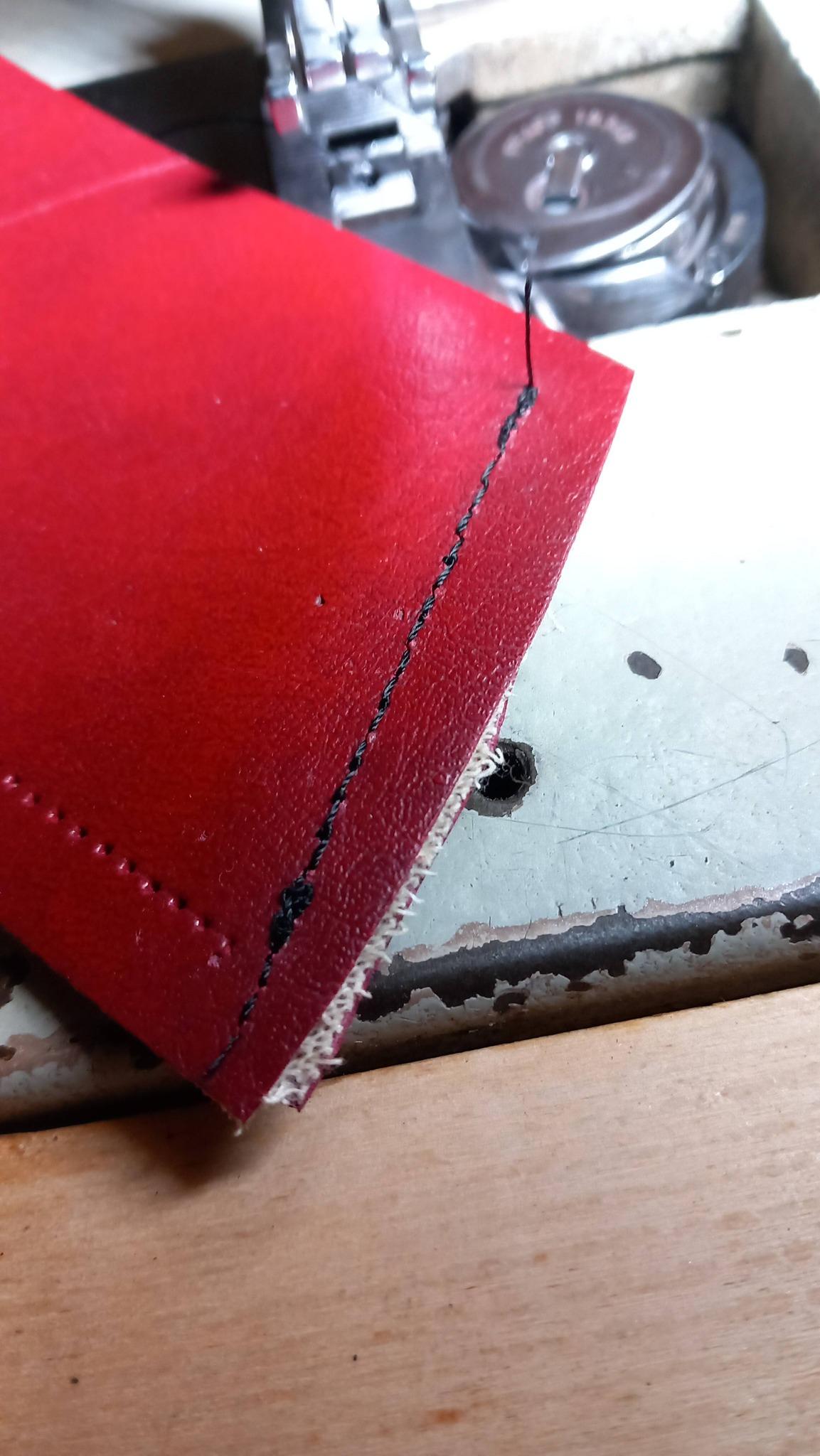

wel with the help of a manual on pdf i started working out the tensions below and above and she sews. the upper threat and the bottom thread. i tried opening up the stitch lenght and she got messy real quick. so i kept tweeking the tension and slowly its getting better. so im gonna go for the bigger stitch length and set her up for that. so i can atleast sew the basic stuff and not mess with it to much. so my next step is putting on the smaller pulley. but geusse what. the axle is conical. and the new pully aint. even a tiny bit bigger so it slides over the entire shaft. so im gonna dril a hole in the axle and make a stop with a ring on it. put the pulley against that. and im gonna make a special filler ring to fit over the conical part and stabilize the pully so it turns perfectly straight and not woble or anything. but im happy she is sewing. also gonna laminate the table with a cheap top so it looks nice and works smooth. eventually clean up the frame and paint it and all. but first she has to make some money before she gets more love 😁

-

thanks man you helped me out big time. i printed the last part of the pdf. and started working those tips and it worked. she is sewing.

-

im an old pro. ive had a upholstery shop for 15 years. back then i bought a new durkopp adler 267. i used that machine without issues all that time. but i was moving and sold my house and workshop. then the sellers of the new place upped the price with 50k so i had to shift my focus to storage. my house and workshop is packed in 4 20ft containers and i have a old farm shed storage hall. as im looking for a new place. 4 months in and bored waiting to find my new place. i thought lets buy a little machine and do a little work. small budget as im paying rent and storage fee,s this one was suposed to be working just needed a little maintenance from sitting a few years. sadly i was mistaken XD so i just wanna get it running and make little projects i can sell again. i cant unpack the storage containers so i have been buying little things here and there to set up a temporary workshop. i have black red and orange thread at the moment so i can do 2 color. ill get to it tommorow again hopefully

-

ah thanks ill print it out and take it with me to my workshop and fight these issues. and see how far i get

-

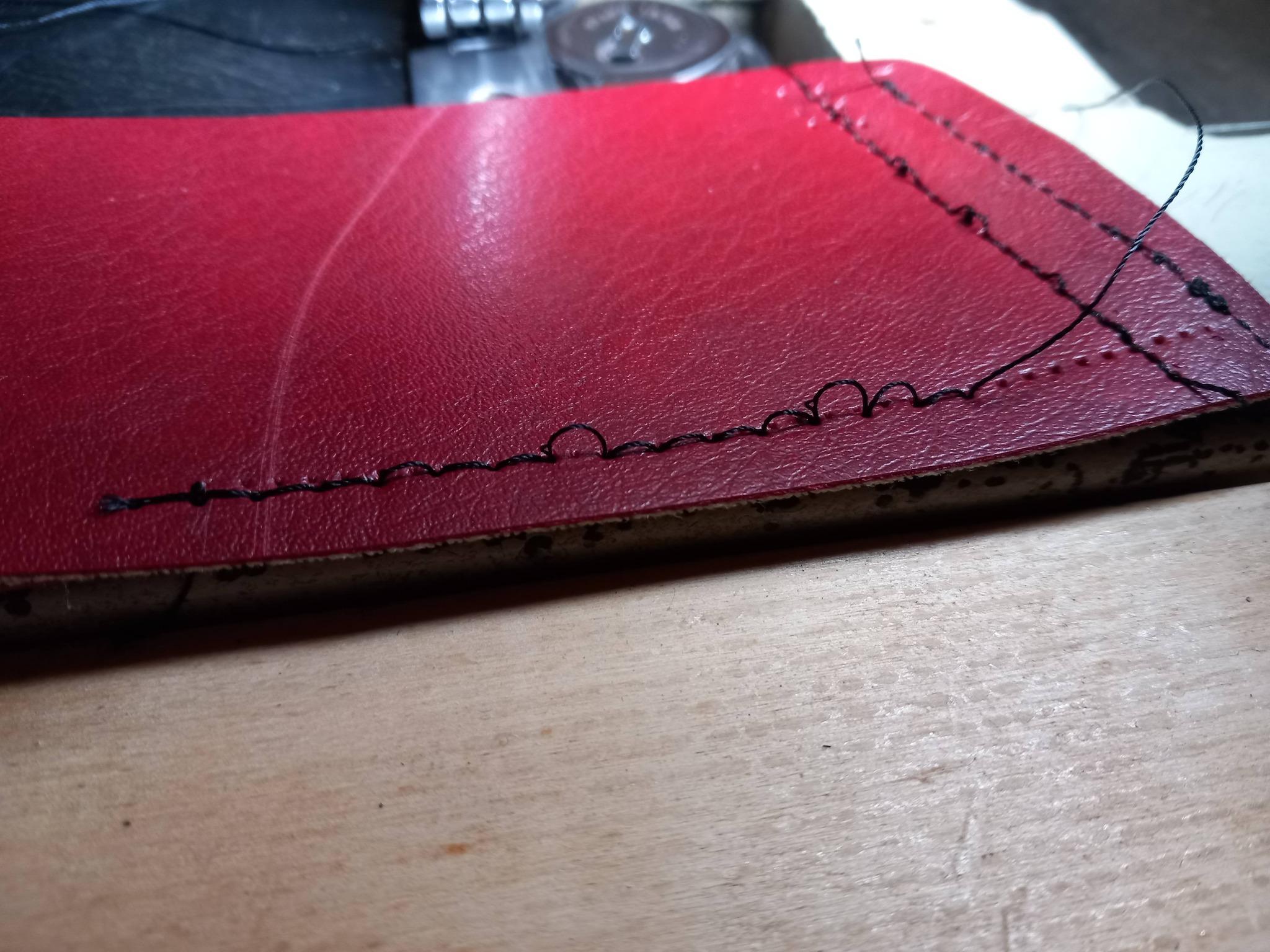

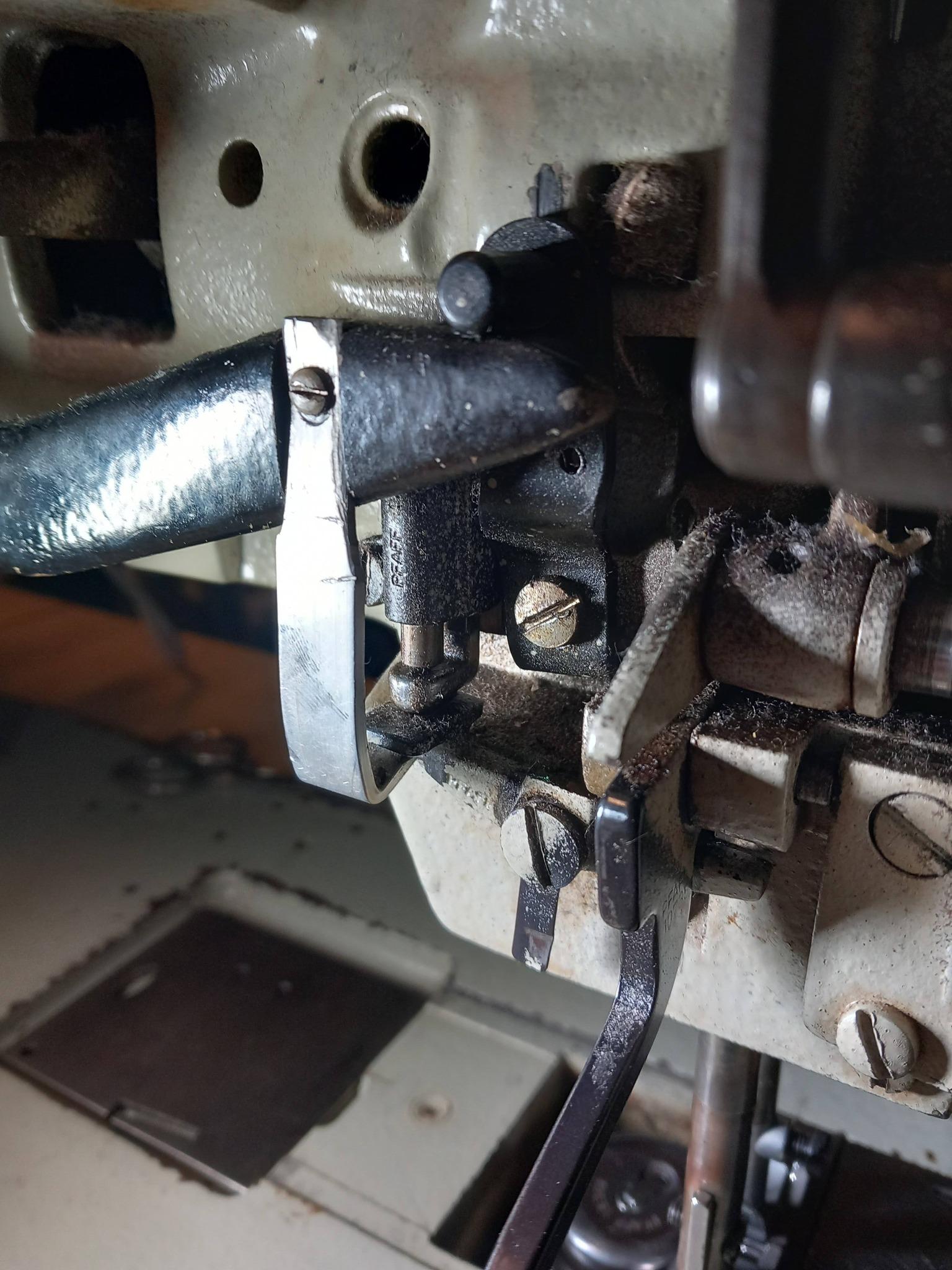

the good news is. i finally got it stitching the bad news is that it inst pretty or good. keeping the smallest stitch length its stitching just not good looking. but when i turn it up for longer stitches it starts messing up badly. so what does everybody think ? is it a tension problem ? any advice would be apreciated. i took apart all the stuff inder the needle i sanded down rough edges and cleaned everything. but didnt find any burrs or nothing. the under side of the feeddog had some carving that was weird in my opinion and everythime i used the knee lifter i heard a click and i found the problem. the bracket that helps take the tension of the top tread when lifting the feet was broken and the home made a piece that slips off and dont do much. so ill go look for a replacement for that. already spend 3 days working on this and i was ready to give up and bring it to a mechanic. but i learned they are hard to find. and the ones i called dont do it anymore only domestic machines. so that sucked. i need this machine to run and work for me. cant keep fiddling for ever on this. and dont have the money to buy another one and find that that has problems to XD

-

yeah thats the plan. open it up and see where it goes wrong. get some good lighting going and see whats what

-

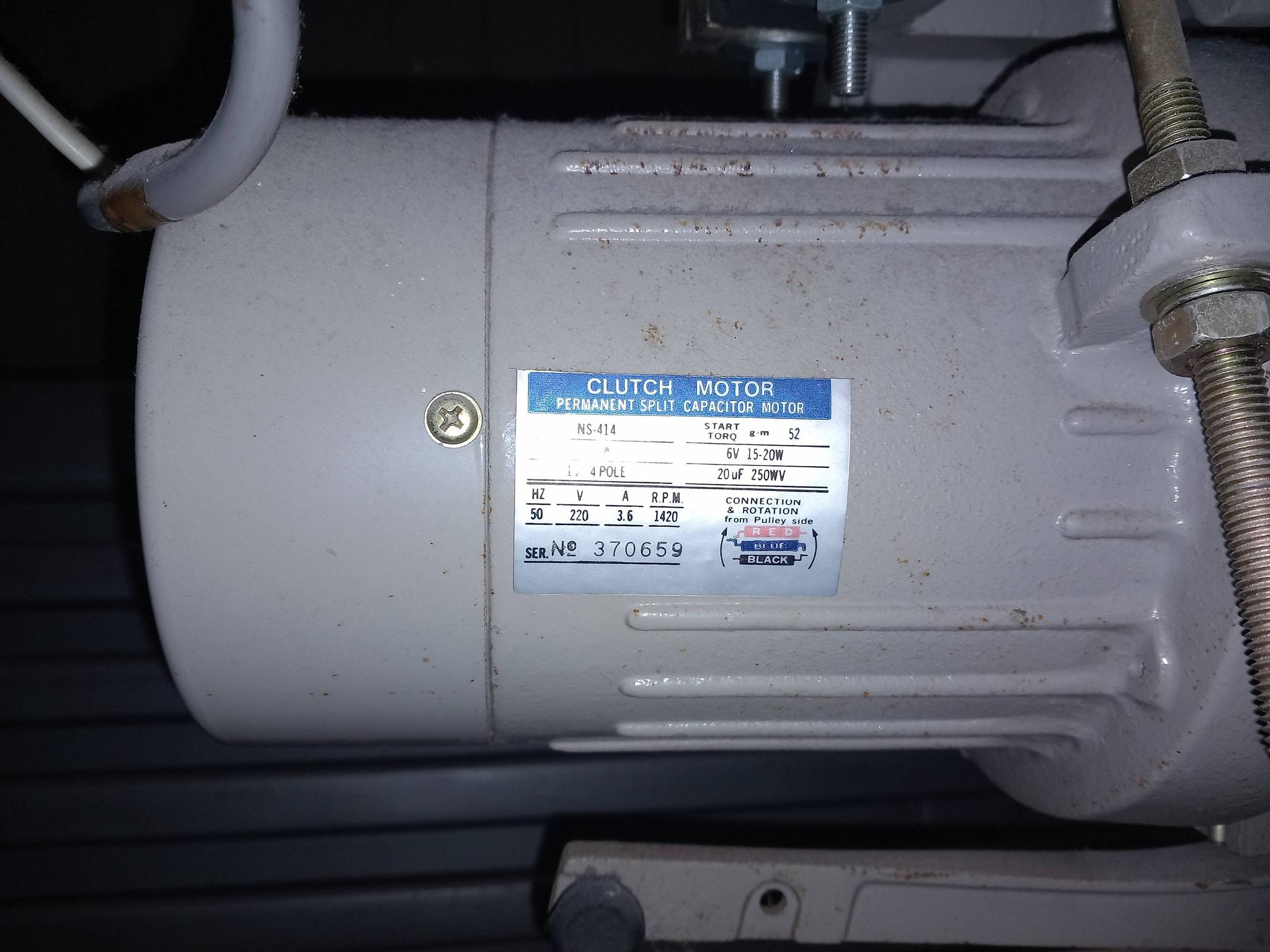

good plan. i believe the axle of the handwheel is 12mm but ill take it of and measure it out and see what i can find. yeah ill learn the work the clutch. it takes time but also cool to learn. easy system for sewing machines instead of the servo motors stil have not found the problem with the tread jamming. see allot of videos, but either they show nothing or extremely to much XD

-

good thinking. ive been raised with a servo motor 😆 sure i always hold on to the ends of the tread. but the needle was always in the up or down position. with the clutch motor ill need to keep my eye on that i geusse. good tip. ill keep my eye on that. i have been looking for a bigger handwheel pulley but didnt find any. so ill keep looking and see if i can find one for this machine. thats would help slowing it down to.

-

i dont have the machine running i was turning it by hand to check if it would sew right. im stil waiting for the new pulley before i can get it running with the motor. i checked the safety clutch that was all good and yes good idea to look for a new belt especially with the smaller pulley smart thinking thank you. yup i believe i ordered the 45mm pulley

-

cleaned up the machine. oiled it. took apart the tensionplate cleaned and polished everything and put it back together. set up the treads and tried sewing and sadly it jammed. 1 stitch and it gets stuck. i turn the wheel a bit back and then i can pull back the material and i have 4 threads coming out so thats not right. if anybody has handy vids. tips. or hints i appreciate sharing them. i geusse im gonna need to adjust it and set it up right. ill go check the manual and see if i can find the problem there

-

checked the clutchmotor and it runs at 1420 RPM thats gonna be a bit extreme for me so i ordered a smaller pulley and see if thats gonna be enough gonna be a big difference hopefully as there was a big one on there.