-

Posts

38 -

Joined

-

Last visited

About DFWLeather

- Birthday September 21

Profile Information

-

Gender

Male

-

Location

Fort Worth, TX

-

Interests

Intenational Business Trade. Hobby: leather & machining.

LW Info

-

How did you find leatherworker.net?

Google

DFWLeather's Achievements

Member (2/4)

-

I wanted to add that the Cowboy has stainless steel feet, which I really like. I'm not sure if the Cobra does or not, but I would certainly get them if it didn't.

-

Winder will get another spool ready for you while you work on other items. It's a very nice thing to have. Foot lifter? Are you talking about the pedal or on foot where the needle operates. Pedal, no need. Foot, as need for different materials and uses.

-

What he said.

-

Cowboy 4500 Delivery And Setup

DFWLeather replied to SWFLholsters's topic in Leather Sewing Machines

The CNC is incredibly fun to use. However, mastering the various software packages to get the brainless machine to work is a big curve. I have to admit, once the software has been done, it initiates code like a loyal soldier. When I don't use it anymore, adios. Fun for now, though. -

Cowboy 4500 Delivery And Setup

DFWLeather replied to SWFLholsters's topic in Leather Sewing Machines

Finally, someone as bad as me. Love the Cowboy and Bob, too. I see the Lathe, nice. I have Tormach CNC, and a newly overhauled Atlas lathe. I had a SouthBend but it was too big and heavy for me to move around when needed, and it wasn't up to the shape I desired. I don't have time to overhaul a lathe. Fun times ahead for sure... -

That's funny. I'm not far behind...

-

I believe they are very similar with a few very small exceptions. There are others better qualified to answer this question than I, since I have not seen or used the other machines. I am very happy with the machine and support.

-

I know it's hard to swing a purchase like this, but when you see what the machine can do, and how simple the design is, you realize it's a bargain. I only wish I bought it sooner. I am the worst "buyers remorse" person in the world, so I often delay purchases for fear of regretting a purchase. Well, I thought about this one a good long time, and read a lot, and received great feedback from many on this forum and others. This is one purchase I really enjoy and know I'll use a long time. Also, it has been my experience that good tools are more liquid than a rolex watch. Most of my "good" tools sell in a day or two. It's simple for me really; if I don't use a tool for six months to a year, it's gone. Time to move on to new projects and adventures.

-

You all are want-to-be Cowboys. You see, you have to live in Texas to be a real Cowboy. Congratulations to all of you. My machine is turning out stuff so fast I don't even know what some of it is. As far as why Cowboy or another? Just research, references and preferences.

-

306055 4033832453337 454665564 N

DFWLeather commented on RinoDiesel's gallery image in Gallery- Our Leatherwork

-

Leather Watch Straps - 20Mm And 24Mm

DFWLeather replied to rhoadrw's topic in Leatherwork Conversation

Here ya' go... Send me an email if you're interested in buckles, sleeves and posts. China has some nice pieces, but it takes a long time to get them... -

Thanks for your comments. When I was looking for a leather sewing machine, my wife's clothing company's sewing room suggested a Juki 563. It was completely rebuilt and looked and operated like new--And it did a good job at thin leather. But as I began to expand into thicker, denser leather, and my projects grew, the machine struggled, and understandably so. It was not designed for the tasks I put it through. Needless to say, I wish they had simply referred me to a heavier, stronger machine like Cowboy. Yes the price was a stretch, and more than I would care to spend on a machine. However, now that I have experienced its abilities, I wish I had known about it sooner and acquired it years ago. Oh, the years of hand stitching and using the awl will not be missed by me. I am really impressed with the quality and strength of the machine. And I would like to add my CNC machine was also manufactured in China. And like Cowboy, American consumers need an intermediary like Bob Kovar to bring in the machine, adjust it, adapt it, and run it through its paces before it reaches you or me. I now realize the machine is a bargain given its capabilities. An industrial, beastly machine that you or I can own. Incredible.

-

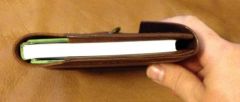

I am grateful to Wiz and others that provided insight and information regarding the various machines. I spent a long time researching the machines, and the people that service them as that is the most important factor regarinding this purchase given the origin of these machines. That said, my machine was delivered mostly assembled from Bob Kovar at Toledo last night. And I can tell you I had it running on leather within an hour. Bob called to follow-up on a couple of questions very quickly. In addition, he labeled all the baggies with the parts and even provided several samples of different thickness of leather he knew I would be sewing to show me the machine was indeed ready. Well let me tell you about this machine, it's a darn beast. Despite its massive heft, I was able to lift it to the table, but don't suggest you do it as it's like lifting the anchor from an aircraft carrier. Here's a link to my youtube account showing the unit in delivery form, and my comments etc.

-

I have both, so I'll give it a try.

-

Leather Watch Straps - 20Mm And 24Mm

DFWLeather replied to rhoadrw's topic in Leatherwork Conversation

Exacto is useless. I've been making watchbands for ten years. You need to see and feel the leather before you buy it. Tandy or other store will meet your needs fine, as long as you can hold it in your hands. Also, be wary of realy oily hides, they'll mess-up a cuffed shirt real fast, this also applies to wax hides. You'll have to double or triple layer your leather if you want something hefty. Also, hand stitching is hard, and time consuming for a beginner, but that's where you learn a lot. try the fold method, it's fast and effective. Fold the leather in half with adhesive in the middle, cut in 23-24 widths, cut off the tail with the shape you prefer (you'll need a tool--tandy has several), and then stitch. Also, the other side requires skiving and layering with adhesive then glue. It's a lot to consume, but it takes a long time to get it right. I began using a Juki to stitch the thread, and it did a fine job. I sold many, and kept many. Selling is tough as people sometimes have too many demands regarding length, tail, width, buckles etc. Tough deal and low margin when you consider your time.