jar944

-

Content Count

11 -

Joined

-

Last visited

Posts posted by jar944

-

-

We used to do a lot of them mainly 226R & Juki 562 that had reverse.We would charge $400.00 for parts & labor.The lower shaft has to be pulled out & take the hook saddle out & then mill it for the larger hook & put it back

together.You also need to change the take-up lever to a longer one.

And change out the bobbin case opening lever as well, CowboyBob know that for sure as well. Not really worth doing this any more, but like said this was a thing at one point. We've had 111W155 machines with big bobbin like this.

So does one use the 563 hook, case opener and take up lever for the 111/226/562 conversion? I ask because I have a 563-3, 111g156 and a 226r and would prefer to convert the 226 to a large bobbin.

Machining is not a issue.

-

That is all you are going to get on a Singer 111W156 or 111W157. Both have reverse and the maximum stitch length on these machines with reverse is about 5.5 SPI.. No reverse like a Singer 111W152-111W155, the stitch length is about 8.5 SPI. Sorry.

shoepatcher

Right, however I *assumed* I could get 5 (not 5.5-6) if everything was set correctly. Also I assume you meant the 152-55 can get 3.5?

I'm happy with 5.5, I can stop searching for the missed/incorrect adjustment.

FWIW the manuals list the max stitch length as 5 to the inch.

-DC

Which should be the max matched, unmatched F and R can offset the linkage to achieve 3.5-4 SPI on F and 25+ on R

I was taking the 5 a bit too literally

Thanks everyone for the info.

-

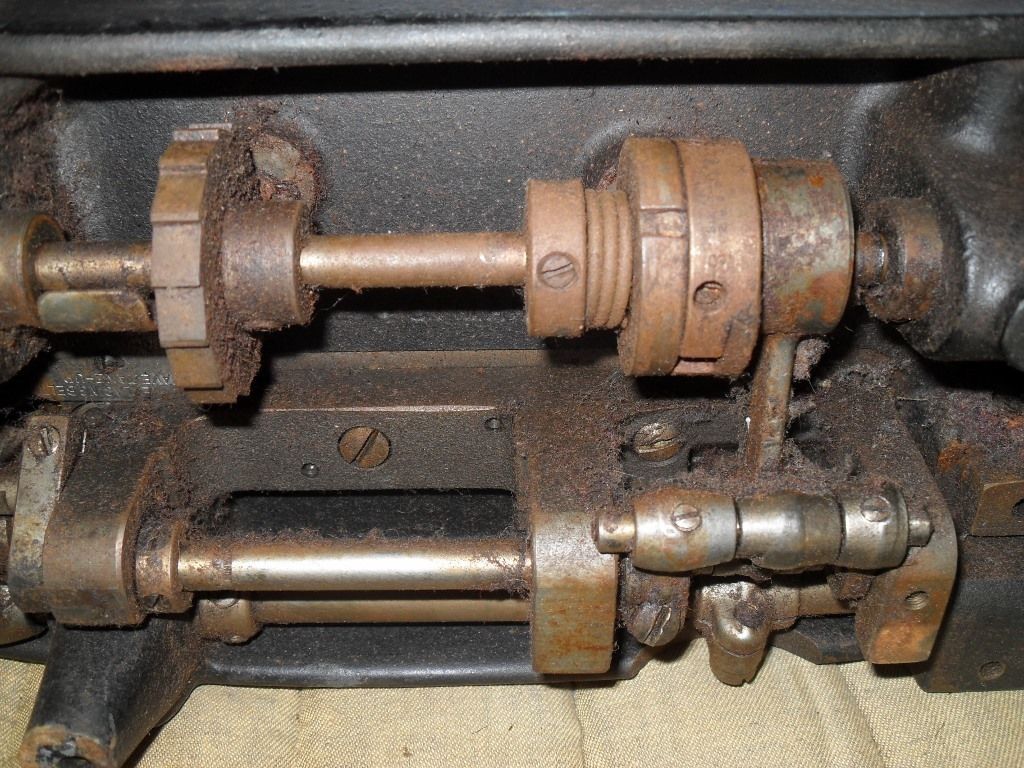

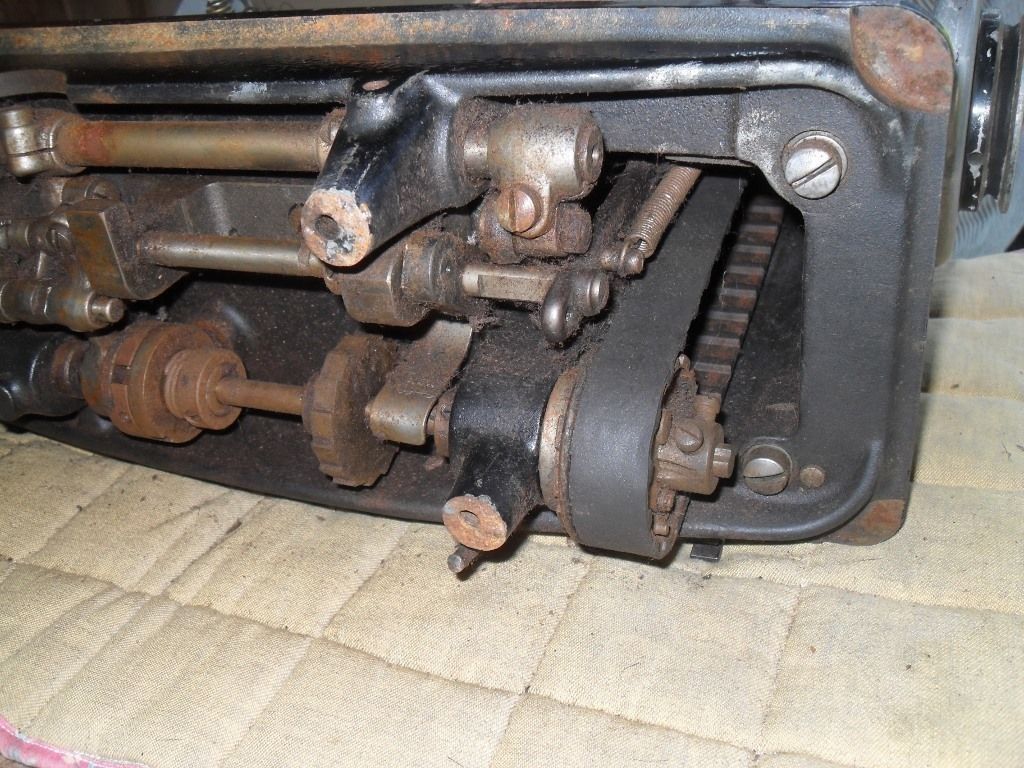

Pics from the original auction listing.

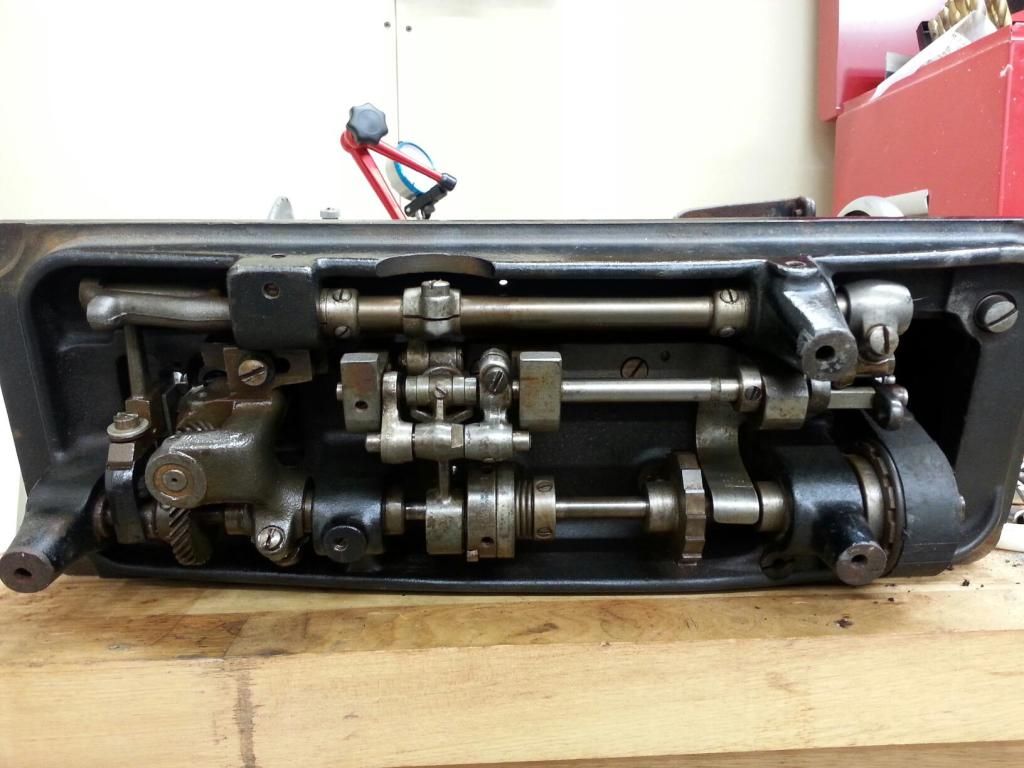

After wiping it down, blowing out the accumulated dust, fuzz, spiderwebs and dirt.

So far Ive checked the timing, moved the saddle, corrected the feed dog height, centered the feed, and adjusted the reverse stitch length to match. I'm still overlooking something as I can only get 5.6-6 SPI with the Forward and reverse matched up.

-

It looks like a fur machine

-

Nice shot! The only reason I could imagine to sell the Juki is that it probably has no reverse. Otherwise I see no advantage for the 111G156.

Thanks. You are correct my Juki does not have reverse.

-

I rolled the dice on a $50 ebay 111g156. Seller had it listed as being locked up. Surprisingly when it showed up today everything was free and turned over w/o any issues. Other than some surface rust to clean up it seems like it should be a easy rebuild. Now I need to decide if its worth keeping my juki 563-3 just for the large bobbin.

-

This is a old topic but, my 563-3 has a max stitch length of 5 spi (both measured and dial setting)

-

make sure you drill holes in the body of the part you fabricated. That part had a wick inside of it with oil holes in it. other parts I would buy since they are not tow expensive. When ordering from Luke at MJ Foley, ask him for both genuine and generic parts and prices. A lot of times, the generic parts are as good as the genuine and a lot cheaper, especially for your Juki since it is a copy of the original Singer 111W155. Just my two cents. I deal with Luke all the time so I know parts and prices.

glenn

Glenn, you are correct. The drive pin got a stepped through hole and three cross drilled holes for the wick and oil dispersion. This was the last (known) issue to fix and I was anxious to test the machine since I had been unable to previously.

I ran it last night and other than needing to adjust thread tension it seems to work well. So far It would appear (at least in my mind) my $145 gamble was well spent.

-

Call MJ Foley in New Baltimore, MI. They are the largest Juki dealer in America. Phone number is 586-948-6070. Ask for Luke. He can get you any part for the Juki LU563.

shoepatcher.

Thanks for the info. I was able to machine the replacement part but ill get in touch with them for any parts I cant fabricate.

-

I just picked up a very cheap Juki 563-3 (seller claimed it was motor clutch issue). It ended up being a bent upper feed spring rod (causing the feed drive rod to bind against the main shaft. That was easy enough to fix in a press and facing cut on the lathe.

However I managed to break the drive pin assembly for the take up arm. I think I can machine a new one, however I would like to have a backup plan it it doesnt work. Ive been been looking for replacement parts(and found a few places look like they have the part) but was hoping to get a suggestion as to a reputable shop to prder from.

Consew 225 Upgrade To Large Bobbin

in Leather Sewing Machines

Posted · Report reply

Great, Thanks for the info.

In my case I only have $310 (total combined) into all three machines, and since swaping parts is free, this will be the low cost option to get the best combination of what I already have.