-

Posts

14 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by thobgood

-

Juki 5550N experiencing problem in the bobbin area

thobgood replied to thobgood's topic in Leather Sewing Machines

Yes! I got the Juki about…8 or 9 years ago? Something like that. (The brain is rapidly disappearing with age.) I primarily make masks for professional wrestlers, and the Juki has really improved my ability to make masks! The knee lift and the large amount of presser foot raise have really been a boon. It's worked flawlessly all this time, so now that it's acting up it's really thrown me for a loop. I do a little leatherwork, but I'm not very good at it. I just do it for friends and whatnot. I do have a Consew 206RB walking foot machine that I use with leather. I find it amazing that it can seemingly sew through anything and take needles that look like decking nails! It's nothing like y'all's Cowboys I'm sure. I'd love one of those, but I can't really justify it with the small amount of heavy duty work I do. They look like wonderful machines though! -

Juki 5550N experiencing problem in the bobbin area

thobgood replied to thobgood's topic in Leather Sewing Machines

I had no idea there was such a latch mechanism. I'll definitely investigate it. It definitely feels like the thread is being yanked past SOMETHING! Thanks for the suggestion. -

Juki 5550N experiencing problem in the bobbin area

thobgood replied to thobgood's topic in Leather Sewing Machines

I forgot to say, if anybody else finds this thread in the future and wonders about hook timing, I found this video quite helpful: https://www.youtube.com/watch?v=GxMT3UfE_tk&t=6s -

Juki 5550N experiencing problem in the bobbin area

thobgood replied to thobgood's topic in Leather Sewing Machines

Update: I checked my hook timing and the hook was touching the needle and moving it slightly instead of passing close to the needle like it should've been. I found a video that helped me adjust the hook timing to be correct. That felt good! I'm still having the issue I described initially, feeling resistance when handwheeling as the takeup lever reaches its lowest position and then feeling two pops in the bobbin area as I add a slight bit more force. I'll do a thorough check for burrs tomorrow. I'm happy I fixed the timing issue though! 😃 -

Juki 5550N experiencing problem in the bobbin area

thobgood replied to thobgood's topic in Leather Sewing Machines

Aha! Thank you. I've learned something! -

Juki 5550N experiencing problem in the bobbin area

thobgood replied to thobgood's topic in Leather Sewing Machines

Which part is the latch? Apologies for my ignorance. Is the opener the part that releases the bobbin case so you can remove it? There's a little hinged latch on the bobbin case that lets you remove it. -

Juki 5550N experiencing problem in the bobbin area

thobgood replied to thobgood's topic in Leather Sewing Machines

Thread is coming off the cone smoothly, that was my first thought too! Someone suggested rubbing a cotton ball over the bobbin area where the thread passes to check for burrs. I'm going to try that next. Thanks! After reading Wizcrafts' note about the thread check spring, I found this video that helped me understand it more. You might enjoy it as well. https://www.youtube.com/watch?v=4758pErWmY8 -

Juki 5550N experiencing problem in the bobbin area

thobgood replied to thobgood's topic in Leather Sewing Machines

Okay, I have made some more videos as requested by friquant. (I've actually made a few more videos, some while the machine is threaded, but YouTube says I've reached my daily upload limit. Grr. I'll try to upload them tomorrow.) Needle plate and feed dogs removed, shot from top left https://youtu.be/gU6iqXo5XkE Needle plate and feed dogs removed, shot from above https://youtu.be/KzAVHOavvZE Needle plate and feed dogs removed, shot from above right https://youtu.be/ecs0gZc86z4 Needle plate and feed dogs removed, shot from underneath left https://youtu.be/lTKJZDKKaQY -

Juki 5550N experiencing problem in the bobbin area

thobgood replied to thobgood's topic in Leather Sewing Machines

A lot to absorb indeed, Wizcrafts, but exactly the sort of information I need! I shall make the video that friquant requested earlier, and then I shall delve into all the information you have provided me. I always see you answering people's questions in here over the years, and that's very kind and generous of you. I appreciate your wisdom and your assistance. Crossing my fingers I'll be smart enough to figure out a solution with the information you've given me. Thank you so much! -

Juki 5550N experiencing problem in the bobbin area

thobgood replied to thobgood's topic in Leather Sewing Machines

I shall do this first thing tomorrow! Thank you so much for the suggestion friquant! -

Hello! I've been a reader here for years and seeing other people's machine problems and the comments from other forum members suggesting fixes has helped me many a time. This week I've experienced a machine problem of my own, and for the first time I can't find anybody who's had the same issue, so I'm posting this with hopes that someone wiser than myself might be able to help me out. I've been sewing for nigh on 45 years now, but I'm still no machinery expert. I can figure out most little things (tension—it's always the tension!) but this one has me stumped. I've got a nice little Juki 5550N that I bought new (back when I could afford to buy things new!) I've had it about 9 or 10 years now I think, always sewing the same sort of stuff, but recently it's been acting up. I've noticed the occasional skipped stitch, and have noticed the thread momentarily going slack now and then. The past few days I've been tearing my hair out trying to diagnose the problem (and I lost my hair years ago, so that take some effort!) I'll list what I have tried at the end of this post, but right now I'll tell you what I've figured out. I think this issue is in the bobbin area, with possibly the thread catching on something or having trouble making it around the shuttle. It still sews and produces nice stitches most of the time, but there is definitely an issue. When I did a test sew just using the handwheel, I noticed that resistance is felt when the take-up lever is reaching its lowest position and just starting to move back upwards. If I continue to move the handwheel, two little pops are heard, as if the thread is catching somewhere and being released. As I mentioned earlier, when sewing with this issue, I've started to see the occasional skipped stitch, sometimes two in a row, and occasionally the thread will momentarily go slack between the take-up lever and the needle, justjsut for a moment. Then it gets tension again. I've made some videos showing the behaviour while handwheeling. I'll link those at the end of this post. Here's what I have tried: I've changed the needle for a new one. I've changed the size of the needle (even though I've been sewing with that size and that type of thread for years with no problem.) I've tried different cones of thread. I've changed the bobbin. I've tried a different bobbin case. I made certain the needle was inserted correctly. I've rethreaded the machine. I've disassembled the upper tension assembly to make sure it wasn't clogged with lint, and carefully reassembled it. I've adjusted the tension to make sure it is correct, and it does form nicely balanced stitches. I've taken off the needle plate and feed dogs and cleaned the bobbin area. I've oiled the machine. I've checked to make sure there are no foreign objects clogging the bobbin area (and there are none I can see.) That's about the extent of my machine knowledge, and now I'm stymied and frustrated. On to the videos! I tried to shoot from a few different angles to give y'all the best views possible. I'm handwheeling slowly so you can hear the pops hopefully. They're happening just as the take-up lever reaches the bottom and starts back up, and I've tried to show both the bobbin area and the take-up area so you can see how they correspond, and have also done a closeup of the bobbin area. Test sewing on scrap fabric: https://youtube.com/shorts/CofAeMaxJ8A?feature=share Needle plate removed, shot from left: https://youtube.com/shorts/794Q-e1iLlw?feature=share Needle plate removed, shot from right: https://youtube.com/shorts/pplD9J6i8Zo?feature=share Needle plate removed, closeup from front: https://youtu.be/9bncMsKGbBE Any suggestions would be SO appreciated. I'm at my wit's end and haven't gotten anything done for a week or more. Between that and the floods, it hasn't been the best of times here in NC! Thanks so much.

-

A friend of mine is allergic to nickel (and about a zillion other things, it seems). He just started leathercraft and is a natural at it, but his skin breaks out when he uses his Tandy swivel knife. I turned him on to silicone fingercots which he says helps a lot, but I'd love to be able to find him a swivel knife that he could use with his bare hands. Does anybody know of a source? Thanks!

-

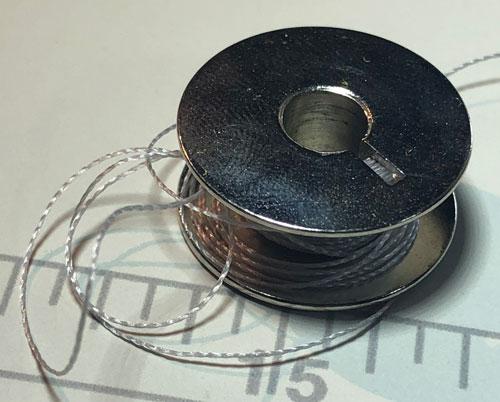

Hi folks! I joined a number of years ago when I got my first industrial sewing machine, as when you google problems with industrial machines, all the best advice comes from leatherworker.net! Now after being a member for a few years, I'd like to ask for advice about a problem I'm having. This is on my Juki 5550N, which I bought new a few years ago. I'd say I use it a moderate to low amount, maybe ten hours a week? So it hasn't been run into the ground or anything. I'm actually not using it to sew a lot of leather, mainly spandex and vinyl (I make pro wrestling masks, yeah, weird, I know.) I'm currently using size #46 bonded nylon thread. I wind my own bobbins on a standard on-table bobbin winder. They seem to wind evenly and tight, quite nice bobbins. I occasionally ( a few times a week maybe) have an issue where I'll be sewing and the bobbin thread will suddenly break, and when I pull the bobbin out to get the thread going again, a bunch of the thread on the bobbin is very loose (where it was nice and tight before). I unwind the loose thread (it's usually about ~15-20 times around the bobbin, what's come loose), rewind it around the bobbin by hand, put it back into the machine, and I'm good to go for hours and hours usually, and then the same thing'll happen. I *think* it only happens when I go to backstitch to reinforce my stitching, but it definitely doesn't happen EVERY time I backstitch. I've examined the bobbin case for burrs or inconsistencies, but don't see anything obvious. Ditto for the enclosure where you insert the case in the machine. The bobbin tension appears to be fine, in that I do that test you read about where you put the bobbin in the bobbin case and you can hold the weight of the case by the thread coming out, but if you bounce it a bit, thread does flow out of the case. (I think that's how you test to make sure bobbin tension is ok, yes?) Like I said, I can sew just fine for hours, occasionally backstitching just fine, and then unpredictably, I'll get the thread break and the odd loosening of the bobbin thread. It's been so frustrating, as you might imagine! I've tried googling the issue and searching for it in the forums here, but when I search for "loosening of bobbin thread," I just turn up the basic bobbin tension issues that commonly happen, not this actual loosening of the thread on the bobbin itself. I've attached some pix of what the thread on the bobbin looks like when this happens, as well as the broken thread. Has anybody ever had this happen to them? Any idea what might be causing this? Many thanks in advance! EDIT: Forgot to mention: I thought that the issue might be the direction my bobbin was spooling when I inserted it into the bobbin case. I checked my manual, and indeed I have been putting it in backwards in this regard for a long time now, but the issue continues to happen even now that I'm placing the bobbin in the case with the correct orientation.

-

IMG 20151031 171657235

thobgood commented on Leather Stash's gallery image in Gallery- Our Leatherwork