Paulcat

Members-

Posts

13 -

Joined

-

Last visited

Profile Information

-

Location

Salem Oregon

-

Interests

Sailing, outdoors

LW Info

-

Leatherwork Specialty

none yet

-

Interested in learning about

Pfaff 145 H4

-

How did you find leatherworker.net?

#1 hit on google search for Pfaff 145

Paulcat's Achievements

Member (2/4)

-

Narrowed it down to the narrow part of shaft being bent. Supplier on ebay of this part for H3 says mine is not available. Will attempt to straighten. Guy I sold some wheels to this weekend is a commercial upholsterer and said he uses standard v belts with hog rings. Thanks for previous input.

-

-

Considering the only info I can find are parts I'm guessing and removing and reinstalling. this photo shows a grey area that I wonder if there is supposed to be a shim. Its like if the walking mechanism was shimmed a little it may correct issues. Cant post photo.

-

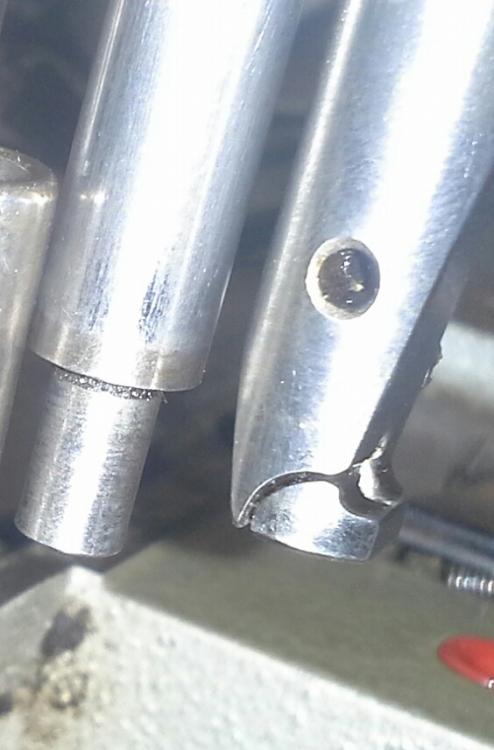

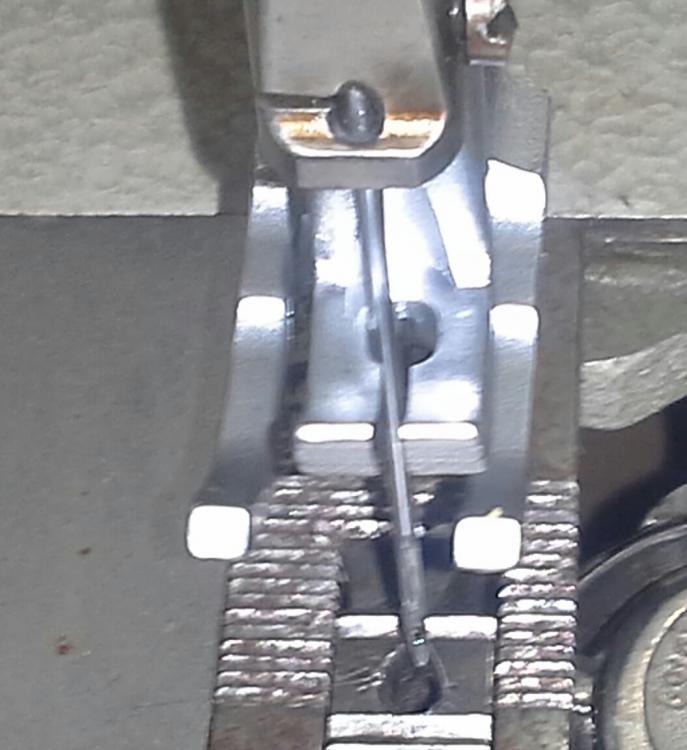

I took out the presser bar? in question and it was fairly straight. Needle/bar is straight. Feet do not match up. Front foot does not sit square if centered to needle. ($95 + parts machine and I dont need parts). Seems more like a shim missing or their is a twist in the vertical cast arm that walks it? Anyone ever troubleshoot/replace these parts before? Based on being damaged or worn? Think their is a commercial sewing machine center near Portland when I give up. I took out the presser bar? in question and it was fairly straight. Needle/bar is straight. Feet do not match up. Front foot does not sit square if centered to needle. ($95 + parts machine and I dont need parts). Seems more like a shim missing or their is a twist in the vertical cast arm that walks it? Anyone ever troubleshoot/replace these parts before? Based on being damaged or worn? Think their is a commercial sewing machine center near Portland when I give up.

-

I was able to check with 2 matching presser feet. Seems as though the front foot mechnism is bent towards the right. they still would bind and needle is off center within foot. I plan to take apart and inspect what I believe to be: part #91-108-002-91 page 37 (10) along with corresponding parts. My Pfaff145 is the H4 the other part similar seems to be for the H3 (108-001-91). So another question along with the belt question is this part available if its bad? (And I think like I'm on the right track.) I had no hits from a search. thanks for reading. Paul

-

I will also need to relocate bobbin winder further back. So that raises the question if the adjustable belts work on their backside? Leather belt seems inadequate. Thanks for input.

-

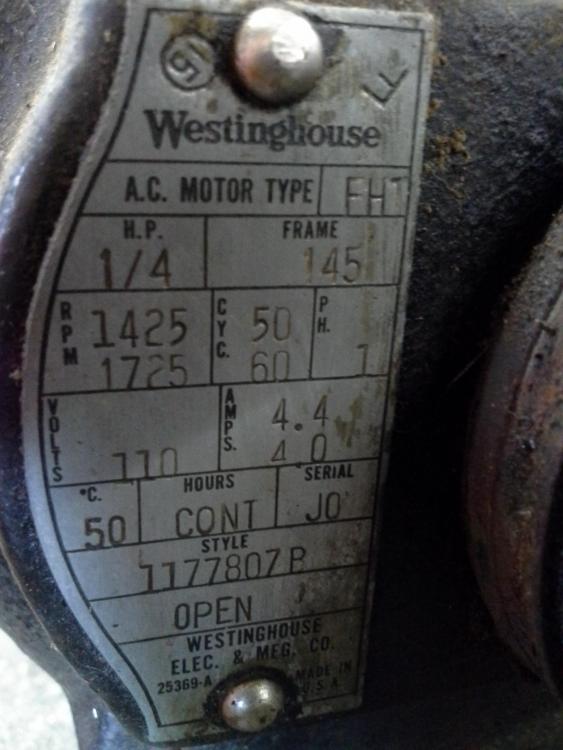

Installed. yes clutch motor..1720. may have to get smaller pulley. So far so good. Would an adjustable belt work so I wont have to cut my table up to much? Friend said "tell them it wouldn't even turn when purchased". Screams now.

-

picking up the following motor in couple hours. leftover from company upgrading to digital. WMC..not quite a sewquiet 6000 but hopefully adequate for a part time sewer. and it looks like the servo type. 1/2 hp $20 Greg, looks like you may have a few things I will want. Going to test machine with other presser feet by weekend and contact you after. With the old motor in position we were able make it run(yay) after lubing and removing one mismatced foot. Maybe I'll get this able to stich yet. 2nd photo is of the welting I will need to accomplish assuming I build my own trampoline. The design would be different but with lots of stitching. Looks like maybe 5/16" (or 3/8) welting foot would be ok? I should ask a trampoline manufacturer cord size used. This possibly 35 yrs old and swollen..a difficult fit in the track for sure. Thanks for comments. I'll do followup after I have more news following week. Coincidentally my mother handed me some hotpads she made out of old material, old curtains, dresses and shirts. I said "no", doesnt look familiar. Few months later she hands me another hotpad and ask if this was it. I said "oh my, thats it!". Remnants of a shirt I made 40+ yrs ago in 5th grade now a hotpad. Anchors, stars and sailboats were the fabrics theme. Who knew I'd enjoy sailing years later.. too bad i live in such a wet region of US.(20" above normal thus far)

-

-

Thank you for the replies, Friend I mentioned...found machine at garage sale for $75..why I mentioned it in first place. This leaves me some repair/parts funds. Yes I have checked feet out(on ebay) and did consider the double toe. Since the material edge I would be using is approx 6" finished I can use the standard piping set. I will determine if its 1/4" or bigger later today and get some photos of that and current(pfaff stamped on them) set of feet now with the machine. Didnt think of them not being matched. I will start with buying a throat plate and regular set of double toe for the feild. This will help troubleshoot further with feet issue and prepare me to repair trampoline. So yesterday I stopped in at an electric motor shop to hopefully get a rubber motor mount bushing..no luck and they were suggesting I wouldnt find one. Its a Westinghouse 1/4 hp..see photo. I'll assume they're right. which means a new motor in the near future once I find out if it everything else is OK within a reasonable budget.. I'll post some more photos by afternoon.

-

I picked up a Pfaff 145 H4 as a friend had known I was looking for a commercial machine to repair and/or replace my catamaran trampoline. I will be replacing motor rubber bushing soon, just finished cleaning and lubing. Next is the feet issue. I noticed more support for this machine from this site(leather specific machinee?) as opposed to a sailors site. For now I will repair old tramp but eventually I will need to sew a cord/piping into material that slides into an awning/c-channel for the sides plus standard stitches where I add/stitch peices together at ends/field. I have just enough sewing experience to give it a whirl. Hoping for some expertise. Not sure if I can upload photos yet. 1) assesment of possible problems with feet as they bind. Front foot inner sleeve seems too loose when attaching and tightening. I only have this pair. 2) (vendors here?) recommendation of feet (prefer quality parts) needed for the future project. I'd like to order a set for the piping 1/4" or 5/16" I believe and regular 2 toe style for the field. And needles..already have some 138 thread. I do notice all welting/piping feet seem to be oriented opposite of what i though would be normal...where excess material feeds inside.2nd photo is what I though seet orientation might be even though different style. Maybe new feet will solve feet issue..otherwise sounds like more of an internal shaft problem. Thanks Paul G