-

Posts

32 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Wonderboy

-

Haha. After I did this work I was then on my car for about 15 hours for a local show and shine. To be honest I’m a little over polishing for a while

-

-

Best base setup for table mount antique machine

Wonderboy replied to Wonderboy's topic in Leather Sewing Machines

Damn. Thanks Kgg... The modern tables look terrible but I guess it needs to be functional first and foremost. -

Hi. I’m after some direction on options for sewing machine bases for an antique sewing machine, which in this instance is a PFAFF 30. At the moment it’s setup to be portable but I’d like to table mount it for light leather work. I was considering a treadle setup but am leaning more towards a servo setup. What are the pros and cons of servo vs treadle in this scenario? Connecting the treadle is straight forward, but if I go with the servo option do I just connect the servo speed controller (rod) to the treadle pedal? I can get a modern looking servo table but wanted to complement the machine with a base of a similar era. I would need to buy a base so just want to know specifically what to look for I go shopping. Thanks in advance.

-

-

-

-

-

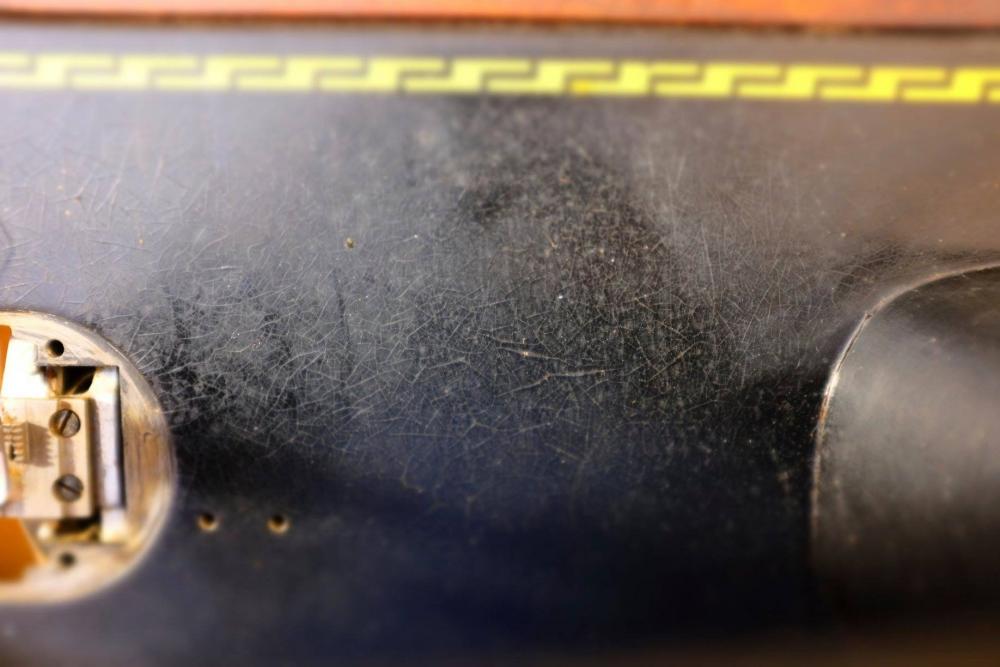

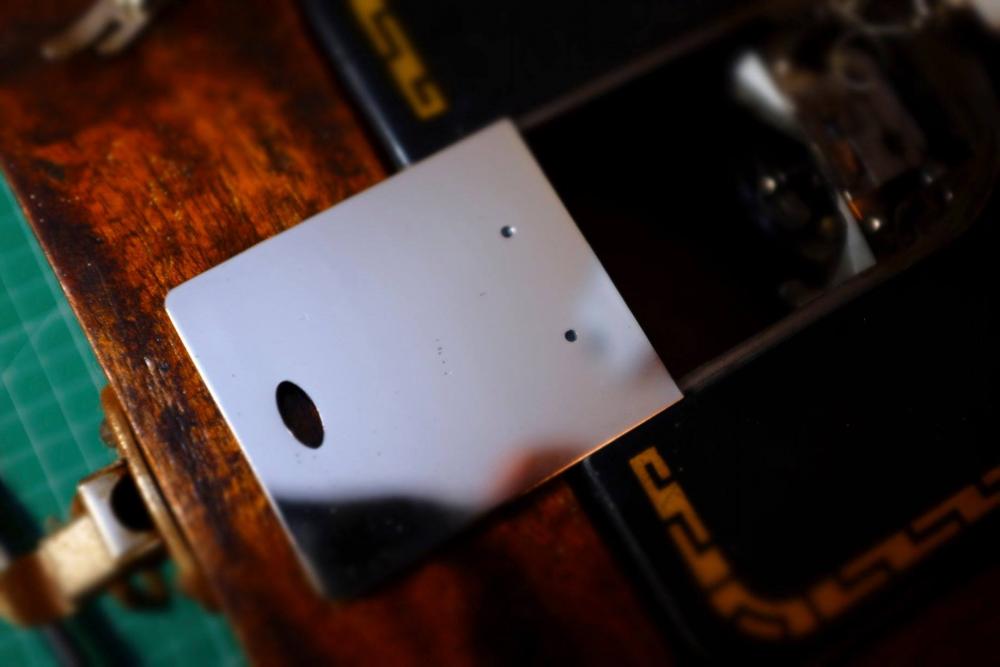

More great information, thanks Dennis! Great to know others on here are using this great little machine. Today I finished cleaning the machine inside and after some kero and some marinating I oiled her up. Much, much better. Everything was turning much more freely. I was also given more parts (incl. original proof of purchase in 1953, manual in perfect condition, etc etc) for the machine by my parents so swapped the old brittle stretched belt with a newer one. After mounting the motor again I noticed, although it’s much better, there’s still slippage from the motor cog on the drive belt mainly at low rpms. I WAS ABLE to sew some kangaroo leather and it smashed through up to 3 layers and I ranged from 2-5mm. I have to say I think it produces a nice stitch. More tests to come. Ive just ordered some #18 needles and bonded 69 thread so looking forward to that. I also finished cleaning it’s exterior too. I hand polished with some car polish for a few hours and then used some quick detailer to remove all polish before topping with car wax several times. All nickle plated parts I’ve polsihed with my car aluminium polish to a high shine. It’s come up a treat..., and I’ll post up some pictures when I can. Regarding the servo motor. How would this fit? I’m assuming if I go servo then I’d probably need to table mount the machine instead of it’s current timber housing? Thanks Darren. I’ve poured about 15-20 hours cleaning it up to this point so good to know the machine is regarded as one of the better ones. I think I’ll stay well clear of the Chinese motors and get a Aussie certified servo setup! Not worth the risk. Id like the control that we have with our 4500 that you sold us

-

Thanks Rocky, much appreciated...!

-

Thanks Ralf. That’s a lot of information and your comments about what they sell cracked me up! I’m taking your advice and will stay away from yaya. I definately don’t need any butt plugs..., lol. I’ll start reading Wizcrafts Singer 15 and persevere with my motor. I should at least give the poor thing a chance. I’m trying to find a replacement pulley (belt) and the one I have is very stretched and brittle. I’ve adjusted the motor but it’s definately the belt that’s the issue. I’m in Australia. Any idea on the best place to purchase PFAFF 30 parts?

-

Very helpful, thanks for this Northmount.

-

Thanks Matt. Appreciate your comments and what you say about the motor makes sense. I’ll get in contact with a local shop. What you say though about online stores also holds true for brick and mortar too. We got burnt big time on our first machine so will not be going anywhere near them again. I may be being overly optimistic at this stage but it would be great if this machine performs as well as the people in the above YouTube videos say it does. I know what you’re saying about presser foot pressure/feed dogs too. While the bobbin isn’t anywhere near the size of our 4500 it is a class15 so not the end of the world. Fingers crossed... *updated* I’ve just found this motor online which is 240v and 1A meaning it would be more powerful than the above 110v/1.5A US motor? It’s listed as being compatible so I may buy it...? http://www.yaya-online.com/-e-n-/shpSR.php?A=26&p1=491&p2=317

-

Hey Jimi. Thanks a lot for the suggestions for restoring! I started tonight and very carefully took of some hardware and polished it to a mirror shine by hand for about 3 hours. I’ve got most of the dust out but plan to put in another 10-15 hours cleaning and polishing. Then I’ll do as you’ve suggested and move onto the painted surfaces. I noticed the paint surface on the machine bed has cracks through it like a dried clay riverbed. I’m not sure what I could do about that...? I’m also after suggestions on how best to restore the nickle plated parts that would be hard to polish by hand. Is there some solution I could use to achieve similar results? Not electrolysis as nothing’s rusting but something like a jewellery cleaner? I’ll keep searching for an answer to the motor. Last resort if I can’t find a local solution would be to buy a step down transformer and purchase the US 110v 1.5amp motor I guess. Here’s a few YouTubes indicating that it should be ok for light leather work. I have a Cowboy 4500 for heavier work and was going to buy a 1618 (or similar) but this may do the job. I’m pretty excited...

-

Hi. I’ve just been gifted a 1953 PFAFF 30 sewing machine and I’m in the process of cleaning it and restoring it in the hope that I can use it to sew small leather goods. It’s the Australian version and has a Wernard 240v 0.38amp motor which still works. The US version came with a 1.5amp motor which, according to the YouTube videos I’ve watched has a lot of punch power (torque) making it a great modification for sewing leather. Is issue I have though is that this motor is only 110v. Can anyone help with shedding light on this machine specifically with using it for sewing leather? Are there other 240v motors which would be appropriate and what other modifications should I consider for it. I’m in the process of cleaning it so haven’t tested the punching power of the 0.38amp motor yet. It’s such a beautiful little machine and I’d love to bring it back to life and put it to use. My step father, who has late stage Parkinson’s, gave it to me and I’d love very much to have him see it working and making things again. He remembers it working from when he was a child. Thanks in advance.

-

I completely missed your reply so apologies for not thanking you. I didn't mean to offend.

-

Hi. We currently own a Cowboy CB4500 but we now require a second machine specifically for smaller leather items, for example things like wallets (kangaroo leather). We have tried "dumbing down" our 4500 but we think we need a second machine. Were looking at the Cowboy range as we've been happy with the 4500. Specifically we're looking at the Cowboy CB0618 or the CB1618 however we can't find a lot of information at all on the machines. We're comparing them against the Cowboy CB227R however we think we prefer the flatbeds over the cylinder arm of the CB227R. We have seen YouTube videos of Uwe Grosse who makes flatbed attachments so maybe that's an option for the CB227R? That being said I like the lower position of flatbeds for the items we want to make as it seems more ergonomic. Can someone please tell us the specific differences between these three machines and also tell us why, even though Cowboy sells them, we can't find a lot of information...? We've also come across the Juki 1508n (flatbed). Thanks in advance. CB1618 - https://www.gumtree.com.au/s-ad/goulburn/sewing-machines/new-cowboy-cb1618-compound-feed-canvas-upholstery-sewing-machine/1163717836 CB0618- https://www.gumtree.com.au/s-ad/bundaberg-central/miscellaneous-goods/cowboy-cb0618-upholsterer-upholstery-industrial-sewing-machine/1117224000

-

Hi. We currently own a Cowboy CB4500 but we now require a second machine specifically for smaller leather items, for example things like wallets (kangaroo leather). We have tried "dumbing down" our 4500 but we think we need a second machine. Were looking at the Cowboy range as we've been happy with the 4500. Specifically we're looking at the Cowboy CB1618 however we can't find any information at all on the machine apart from a gumtree ad and one youtube (Hightex). We're comparing it against the Cowboy CB227R however we think we prefer the flatbed of the 1618 over the cylinder arm of the 1618. We have seen YouTube videos of Uwe Grosse who makes flatbed attachments so maybe that's an option for the CB227R? That being said I like the lower position of the 1618 as it seems more ergonomic. Can someone please tell us the specific differences between these two machines and also tell us why, even though Cowboy sells it, we can't find a lot on the 1618...? We've also come across the Juki 1508n (flatbed). Thanks in advance.

-

I use fine grit sand paper wrapped around a credit card.

-

What Is Best Machine And Model For Sewing Wallets?

Wonderboy replied to Csr111's topic in Leather Sewing Machines

What machine/s would you recommend Brian? Just doing some initial research. -

What Is Best Machine And Model For Sewing Wallets?

Wonderboy replied to Csr111's topic in Leather Sewing Machines

Hi Wizcrafts. We have a CB4500 currently configured to use a 160x23 needle and 138 thread. We'd occasionally like to sew wallets like what's shown above with this machine. Do you have pointers for us (needles / thread etc)? I guess if we were going to make heaps of wallets and smaller items would a second machine like the Cowboy CB227R be ok? Tia -

Thanks Darren. Sometimes my wife and I can be too trusting and naive. Indeed, even had he not delivered the machine personally we felt his communication was great. The fact that he's active on forums like this too was a big plus for us.

-

WonderCowboy...!?

-

-

Hi Leather Workers, We're very excited today. Last week we decided to buy a new Cowboy CB4500 which arrived yesterday. We're located in Brisbane QLD Australia and feel extremely lucky having it personally delivered by Darren Brosowski from Able Sewing on his return trip home from the Leather Expo at Bundaberg. He went out of his way checking into overnight accomodation on his return trip so he could personally drop it off and demonstrate it, even saying to my wife that he would stay as long as we needed which turned out to be 2 hours. The best thing though is that the machine actually does as claimed and has enabled us to move forward. There are a lot of businesses these days who claim to provide good old fashioned customer service but we've found out the hard way by dealing with a different local sewing machine company that this is simply not the case. Thanks so much Darren for making the purchase enjoyable and stress-free. Your communications been top notch. Thank you for literally and figuratively 'delivering'. Here's a picture of our new addition.