charlesfalzon

-

Content Count

29 -

Joined

-

Last visited

Posts posted by charlesfalzon

-

-

2 hours ago, SilverForgeStudio said:Charles- Given the machines' age and what it has probably been through... there had to already be a crack or a fracture line in place for that grey cast iron to split- perhaps a fall or it was hit at some time in its past- the vibration and fatigue finally caught up with it. The cool thing is its only fractured once in each leg- not in a lot of pieces.

If you were closer I would say bring it over and we would do the fix at my shop- That machine is worth fixing in my book.

Well one of the cracks was already there it was holding on 1 half only

-

3 hours ago, jimi said:What size of needle and thread are you using??

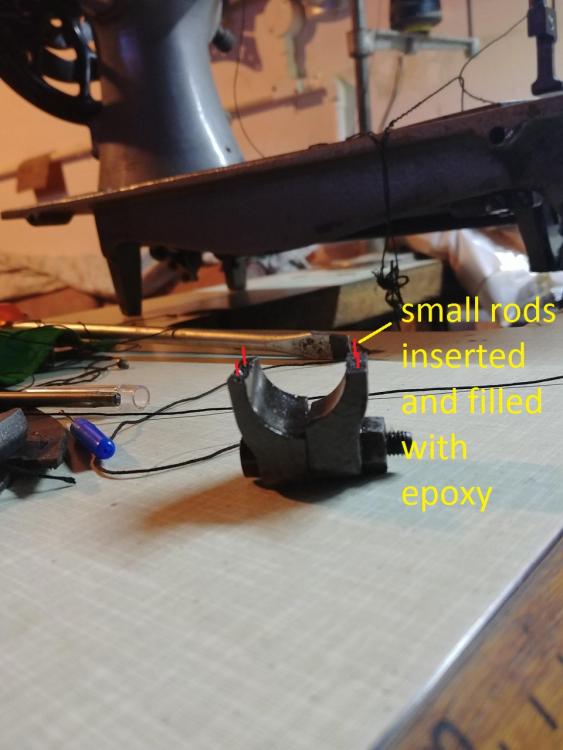

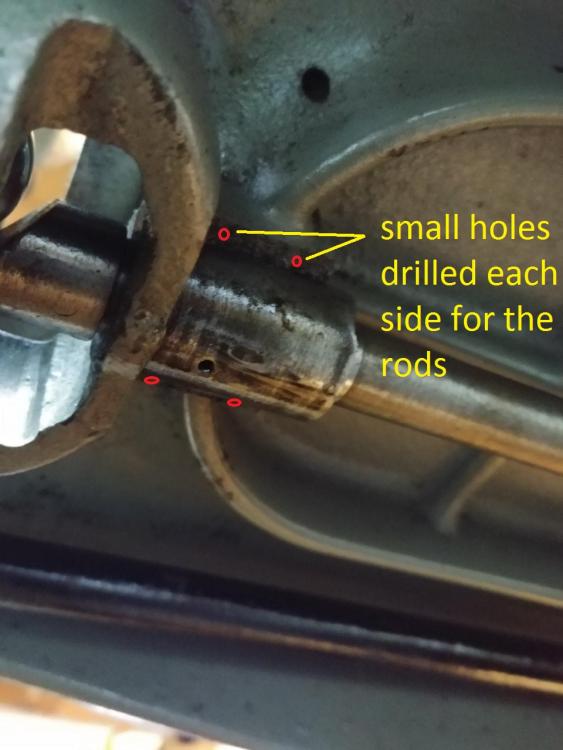

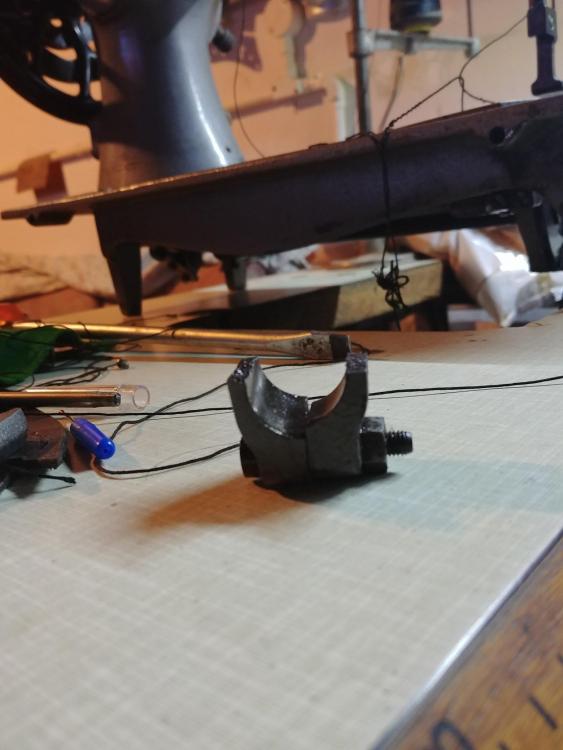

Well at least it looks like a clean break. I would give it a try charlie, it worked well on mine and i had to pass a tap to make the thread on the epoxy side also. You would need to clean well the both parts where the break is, no oil and stuff. I would drill the holes slightly bigger than the rods to help line up the parts, then fill up the holes with epoxy, insert the rods and the join the parts together and let it set. If that does not work then look for a good welder. In the picture i put an example of 2 holes, if you can get 4 each side then better. If you do do it with epoxy then remember to tighten a very little amount.

Thanks gonna talk to dads friend first he has done some brazzing on a clutch motor hinge and he has been welding over 30 years

-

6 minutes ago, jimi said:After that breakage is the bushing loose and turning?? or is it still fixed in its position?? if it is still fixed and not moving then could you send a picture of your thread path.

If the shaft is not wobbling or the bushing not moving and everything is the same as before, then i would leave it. if not then...

I am no expert and only suggesting what worked for me.

What i would do would be to drill some small holes in the casting, put some small rods in and JB weld it. The epoxy sets hard as a brick. Normally i don´t think you would need to touch that bushing unless it was worn or something. The clamp would be to stop it from turning with the shaft i suppose. The other option is to pour the epoxy all over the bushing leaving the oil hole free and just fixing it so it can´t move. i personally would try the first option.

Also in the pictures on the other thread it looks like you are sewing on some thin felt?? try a thick piece of leather if you have some around. I don´t think These machines are meant for sewing thin material.

no its moving if I could upload a video I would but my phone is not working right so everything is slow

Just now, charlesfalzon said:yes it is thin material and I still think the thread is thin

-

9 minutes ago, Matt S said:Did you crank down on the bolt too hard?

I think so as there was already 1 piece broke half so it was holding on 1 half

-

-

3 minutes ago, Matt S said:Well crap, I thought 45s were about bulletproof. Any idea what happened?

There's a lot of threads on here about fixing cast iron. Old school method is to braze with a gas torch. More modern is a decent epoxy. Each has its advantages but better is guaranteed.

Did it cost you much? Worst case you could probably part it out for enough money to buy another machine -- 45k parts are quite sought after

Well no it didnt cost that much but its rare in my country for me anyway

Well what happend is i gave it abit to much gas

-

-

On 13/02/2019 at 3:18 PM, jimi said:Well i have bigger problem now the clamp that holds the middle shaft broke and yes thread was to tin

-

hello again

so I have a problem cant get any tension on the bottom and top tension to tight even with it all open tension dial

I have done everything even I recived a new bobbin case and still the same

I think I am just gonna give up and sell everything

singer 45k

-

On 03/02/2019 at 9:04 PM, GregS said:If I had planned on using it for anything other than stitching practice, I'd have planned out the stitching better. It really only ended up holding my scissors because I noticed that they fit.

Next project is a wallet, I think. Or maybe a belt.

I have never made anything so bought the books recommended by members here but i am trying to setup my sewing machine first and will be practising like you

-

Hello greg i am new too here i used to be a computer guy too

1 thing i would have made the stiching abit closer to the edge but thats just me probably i am wrong and someone qualified can give a better answer

-

30 minutes ago, zuludog said:Here are two books I can recommend -

'The Leatherworking Handbook - a Practical Illustrated Sourcebook of Techniques and Projects' by Valerie Michael

'Leatherwork - a Practical Guide' by Chris Taylor

There are dozens, probably hundreds, of videos about leatherwork on YouTube, watch as many as you have the stamina for. Make it easier by Searching for different aspects and categories - beginners; tools; or particular items, as in your interest list

I can recommend videos by Ian Atkinson and Nigel Armitage

Have a look at the websites for Tandy, and Goods Japan. They will give you an idea of the types & prices of tools, though there are many other suppliers Try Searching Google for 'leather tools europe'

Don't forget this forum! Especially Getting Started; Tools; and Sewing. It's almost certain that most of your questions will have been asked before

Have a look at this supplier; they are Italian, and might be easier for you to buy from https://buyleatheronline.com

I got something similar to the books you mentioned but about woodwork

so gonna buy some for my collection too ( I collect those types of books )

the website you mentioned looks pretty good as it tells you what type of leather you need

so for someone like me that never did leather apart from a leather apron but by hand not with machine

thanks

I forgot to mention I am trying to learn how to sew with a machine ( singer 45k)

thanks for the plentiful info guys I really appreciate it

-

1 hour ago, chrisash said:Nigel armitage is a expert with many video's on Youtube and also dow a great video course selection of about 50 videos with new ones most months but for this selection makes a £3.00 charge monthly but well worth the money

see https://vimeo.com/ondemand/armitageleather/247495554

I will probably contact nigel and buy his pdf

thanks

1 hour ago, fredk said:For any beginner; you can't go wrong having some of Al Stohlman's books handy. He did some on making cases, on making bags, on making wallets and purses. He teaches the basics in a very easy to understand way. Once you know those basics they can be applied to other projects.

Also, having read his books and seeing his instructions helps you to understand what people are doing in some youtube videos

gonna be searching for his books today

thanks

-

Hello

Sorry to bother you again but i need help to start

In my country (malta) they dont have any leather course so i was thinking maybe someone can recommend something like dvd or books

I am interested in wallets bags and motorcycle seats and car upholstery maybe boat stuff too

Thanks for any help

-

2 hours ago, Constabulary said:dam buddy u just saved me a ton of headeachs plus I didn't know tht spring belongs to it it was in the drawer I cant thank you enough

-

-

I tried to sew a zipper awhile ago it didn't go that well couldn't get the 2 parts together

this is also useful for me

I am also in to motorcycles but only managed to do cars the last one my dads 72 buick Riviera

-

15 minutes ago, Constabulary said:Original Singer parts are a lot nicer but you no longer can buy OEM Singer parts - some dealers may have old stock parts but good luck finding them.

I have ordered one of the above mentioned sets for my 45D91 and the parts do work. They are as expected - functional but not beautiful. Well, they work and are well worth the money. I cannot speak for all Chinese parts but he above mentioned parts have good value for money ratio. I would buy them again.

yeah they look ok as long as they fit and do what they're meant to do

-

very nice collection I envy you as I am myself a vintage/antiques collector

-

5 minutes ago, Constabulary said:The Singer 45K92 is a flat bed machine - so feed dog and needle plate from the above set do not work but the presser foot will fit.

Keep in mind that the 45K came as flat bed machines (like yours) and cylinder Army machines like the 45K91, 45K25 and so forth - that's a big difference!

College Sewing in the UK has 45K flat bed needle plate and feed dog for a reasonable price:

https://www.college-sewing.co.uk/store/Singer45KSewingMachineParts

thank you

was just wondering about Chinese stuff if they good

-

looking for the side bar to lift the foot with your knee

-

-

On 9/9/2016 at 11:02 PM, Uwe said:Very cool photo ,Thomas! That is the first time I've seen that outer feed drive wheel of the Singer 18-3, which is a very interesting and different feed transport solution. I always wonder if they made those left-handed machines for actual left-handed operators or if there is some other reason for the left-handed design.

I happen to have some (maybe a lot - not really sure yet) Singer 45K parts, mostly used, some new. Nearly all of them are still hiding in dozens of unorganized parts cabinets/drawers I acquired recently.

I put some Singer 45K open frame shuttle hooks (91774 or DD1OP) and Singer 45K Feed Dog Carrier frame (91160) on Ebay. You may not need those, but I thought I'd mention it.

Good luck with your restoration! You appear to be doing a very nice and thorough job. I'm looking forward to seeing some before/after pictures and perhaps some video snippets of the machines in action.

Hello

I am new here and just so this post

I know this is old but did you find the singer 45k parts i have a 45k92 trying to decide what i am gonna replace

Also the side bar for the knee lift is missing is that worth finding

-

6 hours ago, hwinbermuda said:Welcome, that's a steal for that machine in working order. Well done.

well I got a 95k40 recently too ( I have a fb group and took the advice from a friend to stop spending money on the game so with that money I bought the 2 sewing machines for a good deal

thanks for the welcome

.thumb.jpg.6c7795f6459f08810153873bb0b166f6.jpg)

.thumb.jpg.5547972998068ff0f31f4230c0f1acbc.jpg)

.thumb.jpg.b8966663818561b5c860ee30fd6cddee.jpg)

.thumb.jpg.3c911b2fad39d588b17e3018eb7bc8f9.jpg)

tension problem

in Leather Sewing Machines

Posted · Report reply

Sorry didnt know i had to put it there thks