pgc

Members-

Posts

11 -

Joined

-

Last visited

Profile Information

-

Location

Sacramento, CA USA

-

Interests

Gear making

LW Info

-

Leatherwork Specialty

I use heavy synthetics to make bags, but I don’t use leather.

-

Interested in learning about

Industrial machine maintenance

-

How did you find leatherworker.net?

Search results keep pointing me here

pgc's Achievements

Member (2/4)

-

Searching for a 3/8” gauge set for Mitsubishi LT2-230

pgc replied to pgc's topic in Leather Sewing Machines

Hi! Sorry, but I did not see this question until now. I did not order OEM parts. As noted earlier, they are very expensive. I ordered this feed dog, needle plate, and needle clamp for a Juki LH-3578A-7, as it appeared to have the correct dimensions. It fits perfectly and I am now running a 3/8” gage. It was $32 USD. https://www.ebay.com/itm/144330362304?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=srvQhjPuSfm&sssrc=2349624&ssuid=6ukoqdfzqwq&var=&widget_ver=artemis&media=COPY -

Searching for a 3/8” gauge set for Mitsubishi LT2-230

pgc replied to pgc's topic in Leather Sewing Machines

Thank you! I think I could adjust things to get some of this to fit. But I can’t see how the feed dog is going in. The project you posted looks awesome. I’m going to read that thoroughly and perhaps try it down the road. Thank you! Hi there and thank you! I’d like to follow up with you about ordering. What’s the best way to reach you? -

Searching for a 3/8” gauge set for Mitsubishi LT2-230

pgc replied to pgc's topic in Leather Sewing Machines

I got my hands on a 3/8” gauge set for a Singer 212. With the exception of the needle clamp, it does not appear to fit. The Singer presser foot is 1/2” too tall. The needle plates have the screw hole on the front and the recessed bit on the rear edge different relative positions, and the feed dog screw holes attach to a different part of the piece (it attaches lower on mine, meaning my feed dog sits about 1/4” higher. I’ve attached a picture of the sets side by side in the album here: https://imgur.com/a/C5kw13i I’m going to keep looking and will check back here to see if any new info is posted. Thanks! -

Searching for a 3/8” gauge set for Mitsubishi LT2-230

pgc replied to pgc's topic in Leather Sewing Machines

Also, now that I look closely, I note that the presser foot and needle plate have both been ground. I’m not sure what they looked like to start with. Adding a couple close ups to the album above. I’m going to get my hands on a 212 gauge set today and compare side-by-side. -

Searching for a 3/8” gauge set for Mitsubishi LT2-230

pgc replied to pgc's topic in Leather Sewing Machines

Thank you! The photos appear to be too large to post directly. I’m posting several close ups to this link on Imgur. https://imgur.com/a/C5kw13i -

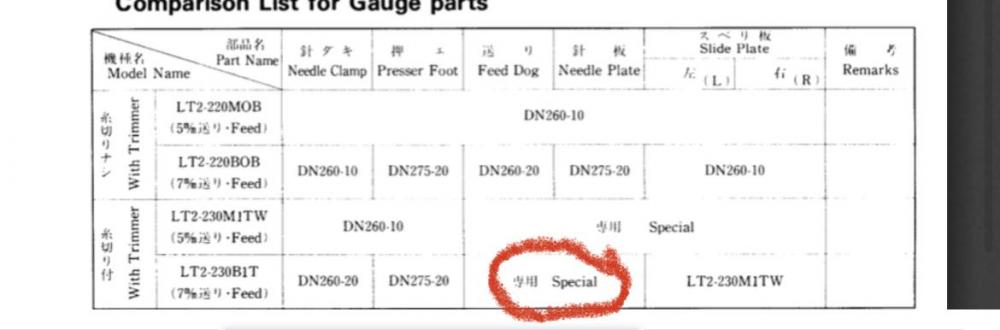

Hi all! I just received bought a dual needle, needle feed machine. It is a Mitsubishi LT2-230 BIT. It has a one piece needle bar (no split ) and a thread trimmer (I explain why this matters below) I’m looking for a 3/8” gauge set. I’ve searched the internet exhaustively, including this forum. Here’s what I’ve found. The Singer 212 style fits the model 220 (like mine, but with no trimmer) but does not fit my model with the trimmer. The parts book has a table for gauge parts and it includes part numbers for the needle clamp (DN260-20) and presser foot (DN275-20). Unfortunately, it says “Special” for the feed dog and needle plate, and I don’t know what to do with that. My local industrial shop is also stumped, but they don’t sell Mitsubishi, so I understand. Do any of you happen to know what gauge set fits this machine? Thanks in advance!

-

Seiko STH-8BLD-3 - Help diagnosing noise at low speed

pgc replied to pgc's topic in Leather Sewing Machines

Will do. I’ve been using an automotive belt. I’ll search the forum for thoughts on sewing machine specific belts and go from there. Thank you! I’m a moderator on Reddit Make Your Own Gear. We often refer the really difficult machine questions to this forum. Thank you for being a great resource!- 8 replies

-

- noise

- consew 206

-

(and 1 more)

Tagged with:

-

Seiko STH-8BLD-3 - Help diagnosing noise at low speed

pgc replied to pgc's topic in Leather Sewing Machines

Thanks! It was the belt. It was too tight. I loosened it and it is running very smooth now. So nice to have it quiet again.- 8 replies

-

- noise

- consew 206

-

(and 1 more)

Tagged with:

-

Seiko STH-8BLD-3 - Help diagnosing noise at low speed

pgc replied to pgc's topic in Leather Sewing Machines

Found a suggestion to loosen belt. I thought it was plenty loose, as it had almost 1” deflection. Loosened it significantly and the noise is gone. fingers crossed it doesn’t come back.- 8 replies

-

- noise

- consew 206

-

(and 1 more)

Tagged with:

-

Seiko STH-8BLD-3 - Help diagnosing noise at low speed

pgc replied to pgc's topic in Leather Sewing Machines

Here is the video on YouTube (in case you don’t use Imgur): https://youtube.com/shorts/yIBxxLMi13w?feature=share- 8 replies

-

- noise

- consew 206

-

(and 1 more)

Tagged with:

-

Hi! I have a Seiko compound feed (STH-8BLD-3). I’ve been using it for about one year making backpacks (not leather). The problem - At low speed, the machine intermittently makes a low pitched rattle/groan. I cannot hear the sound when I turn the machine by hand (with or without the belt on the pulley). The sound goes away as soon as I speed the machine up. Here is a short video with sound. https://imgur.com/a/XNju9LX The sound really comes through in the video. It’s not quite that bad in person, but it’s bad enough that I don’t want to use the machine until I fix it. Background - I tuned it when I got it and lubricate it regularly. I don’t recall when it started making this sound. Maybe it happened gradually. I lubed it the first time I heard it, and it didn’t help. I’ve now removed all the covers, checked everything for loose parts, removed the hand wheel and remounted it, removed the needle position sensor, etc. I swapped the servo motor with another machine and replaced the belt. Nothing helped. The machine still sews very well. It seems like the sound is coming from the middle of the machine, in the enclosed area to the left of the upper oil reservoir. But it is hard to know. I tried a mechanics stethoscope, but the noise is so loud that I can’t pinpoint anything. There are no sewing machine mechanics in my area except one shop with a really long waitlist, so I learned to fix all of my machines. But I’ve spent a couple nights on this and I’m stumped. I’d really appreciate any suggestions. Thank you! Phil

- 8 replies

-

- noise

- consew 206

-

(and 1 more)

Tagged with: