Samer

Members-

Posts

19 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Samer

-

By the way, the Cowboy clone of the Claes, should be arriving in the US in about six weeks, the price is $5000. That includes head stand and motor.

-

I hope you find that English translation, if anyone you do, please send it as soon as possible. Please tell me how much I owe you for your time? And whose name I should write the check and where to send it? If I may ask you a couple questions I know they’re not out yet, but the cowboy clone of the Claes should be coming to the US in a few weeks, do you know or have any secondhand information if they are worth it? Also, I’m interested in starting saddle repair. In your opinion, which would be better the CB4500 or Cobra class 4?

-

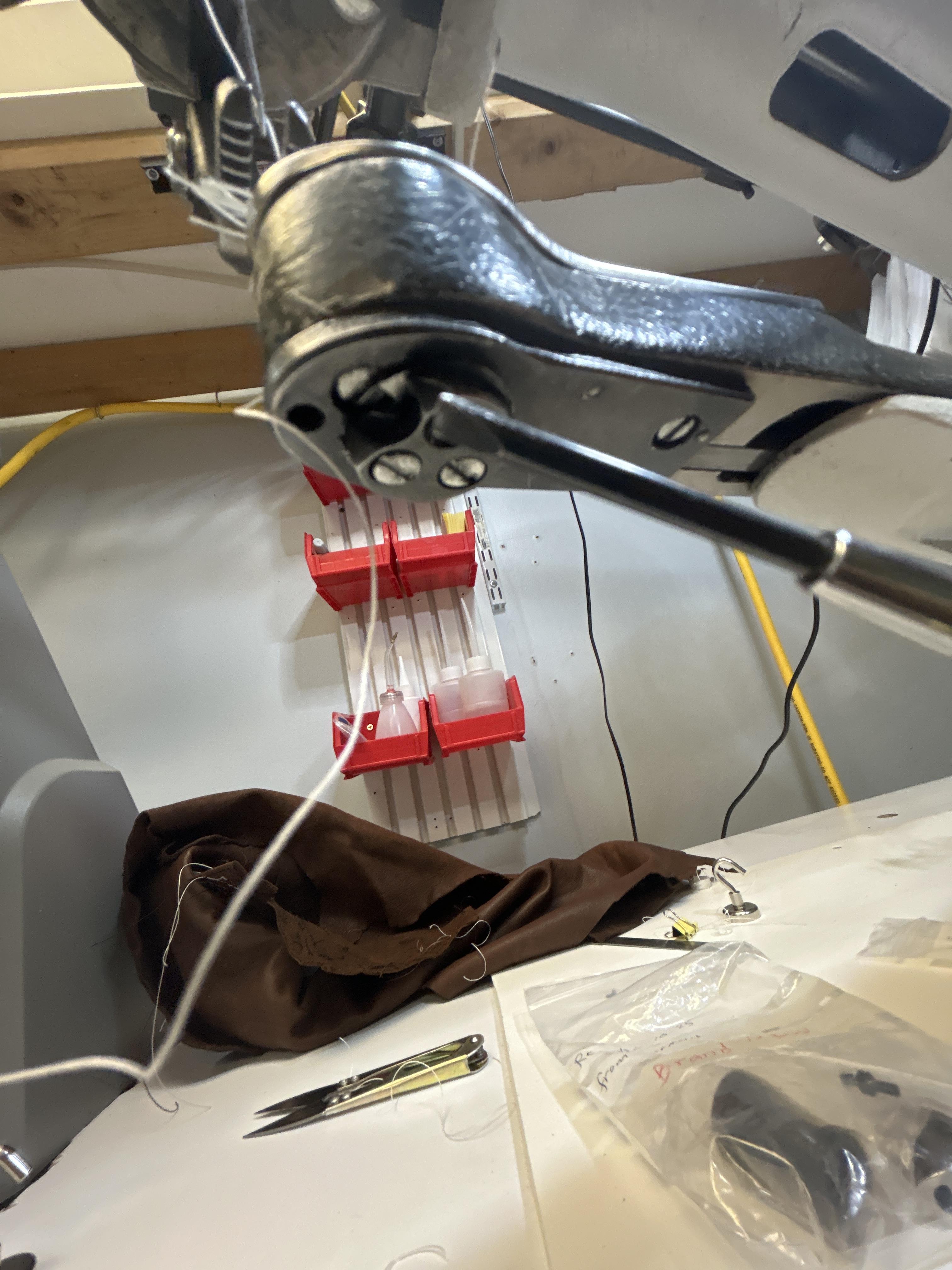

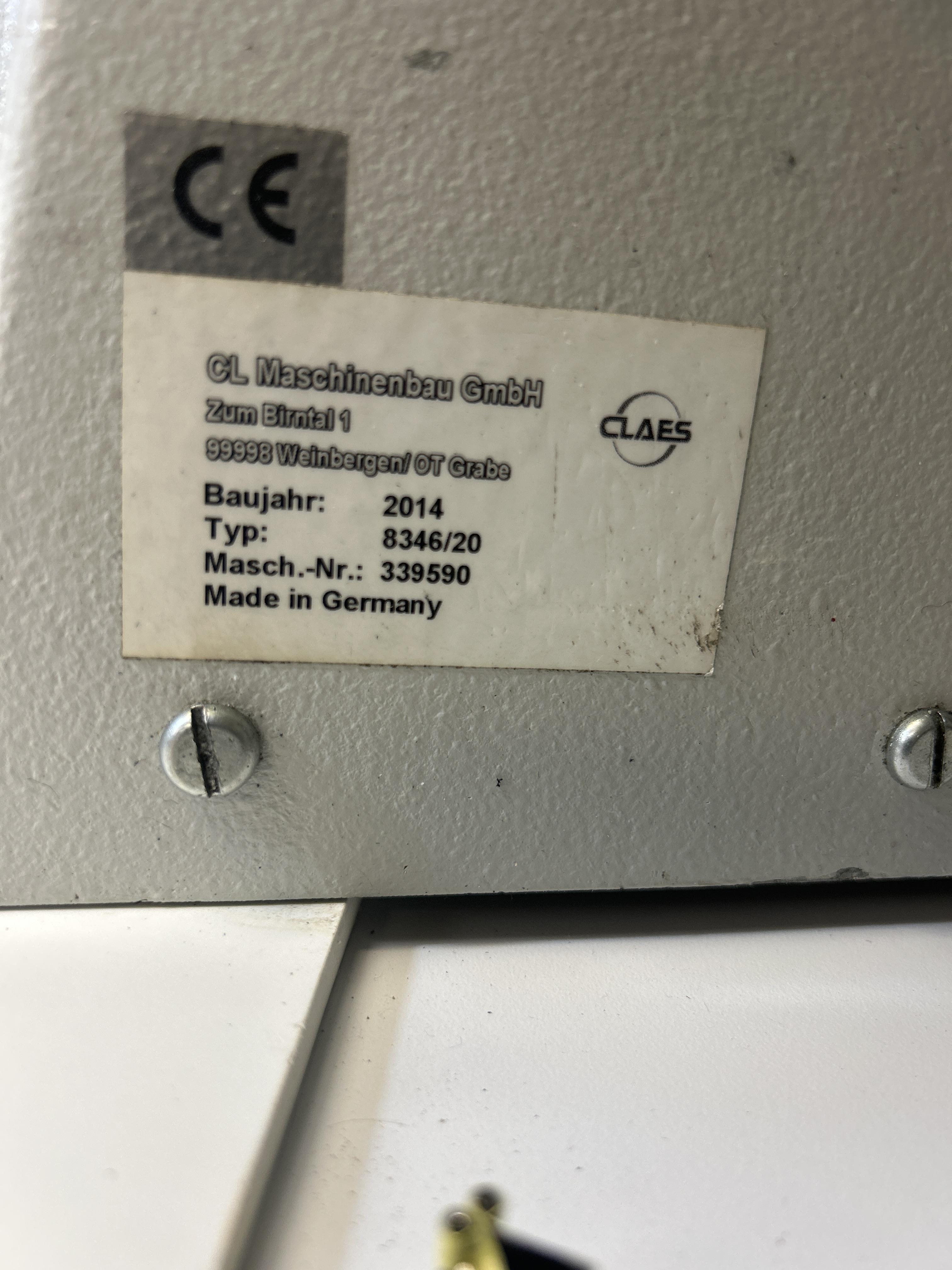

I really appreciate your help. So we won’t get confused the first machine we will call machine #1 It’s not working 95% correctly. The second machine we will call machine. # 2 , which I purchased 10 years ago. I’m having timing issues with it. Since all Claes machines are the same, I tried to adjust the timing of machine #2 to the same timing as #1 but no success. please note the second and third photos are the same but from different sides. I apologize if I’m confusing you with the descriptions I’m sending and also the photos and videos. I’m 60 years old and not computer savvy. The following is how I have threaded the machine. 78501902954__897B199B-5A3D-4478-933F-9F8AC642717F.MOV

-

This is the other end of that arm that I sent you the video tape off. 78501837289__24339A00-5D8B-4808-8111-8B94FB3A4AFC.MOV

-

One more thing I like to inform you of. There is quite a bit of play at the end of the trip of the arm. 78501818481__899B42F4-DEA4-405E-B3F3-DAE2255951F2.MOV

-

I really appreciate your help. So we won’t get confused the first machine we will call machine #1 It’s not working 95% correctly. The second machine we will call machine. # 2 , which I purchased 10 years ago. I’m having timing issues with it. Since all Claes machines are the same, I tried to adjust the timing of machine #2 to the same timing as #1 but no success. please note the second and third photos are the same but from different sides. this is where the top thread ends up and the machine just stops completely.

-

By the way, less than a year ago, I replaced the following parts. The machine was working flawlessly, but then the machine would stop completely. After looking around. A noticed the following wedges which I removed and ever since the machine were just not work well even though I put them back. I was told by Landis International these wedges are not part of the original machine. Even though I am the only owner of that machine. But then I remembered having someone work on this machine about five years ago, and the only explanation I can offer is that he must have put these wedges in there.that would be the tip of my screwdriver pointing at the end of the wedge. I’m going to take them out and show them to you.

-

My apologies to you, I was so in a hurry to show you and tell you what was going on. I forget to send that information.

-

I really appreciate your help. So we won’t get confused the first machine we will call machine #1 It’s not working 95% correctly. The second machine we will call machine. # 2 , which I purchased 10 years ago. I’m having timing issues with it. Since all Claes machines are the same, I tried to adjust the timing of machine #2 to the same timing as #1 but no success. please note the second and third photos are the same but from different sides.

-

Hello, I am looking for an industrial sewing machine Mechanic, who is experienced with fixing Claes Patchers, it has to be through Face Time. I contacted Landis International they could not help me with the issues, I was surprised. Willing to pay. I’m in desperate need of having two Claes Patchers fixed. 603 952 4818. Northeast time zone.Thank you.

-

Reommendations for Getting into Saddle Repair

Samer posted a topic in Saddle Supplies, Tools & Trees

Hello folks, I have a Shoe Repair, I have done little saddle repair work. I’d like to get into the saddle repair service. And you recommendations where to start and what to get for startup tools? Are there any online schools? Any comments or recommendations are appreciated. Sam -

thank you. Finally got a direct answer to my question. Very helpful information.

-

The machine is all ready in the states, so there are no tariffs all I have to do is order it. I still like to know the reliability of Techsew machines. If anyone can offer some input, it will be appreciated.

-

Hi again, it is the Techsew 860 not 850, anyway it’s the walking foot model ( post bed).

-

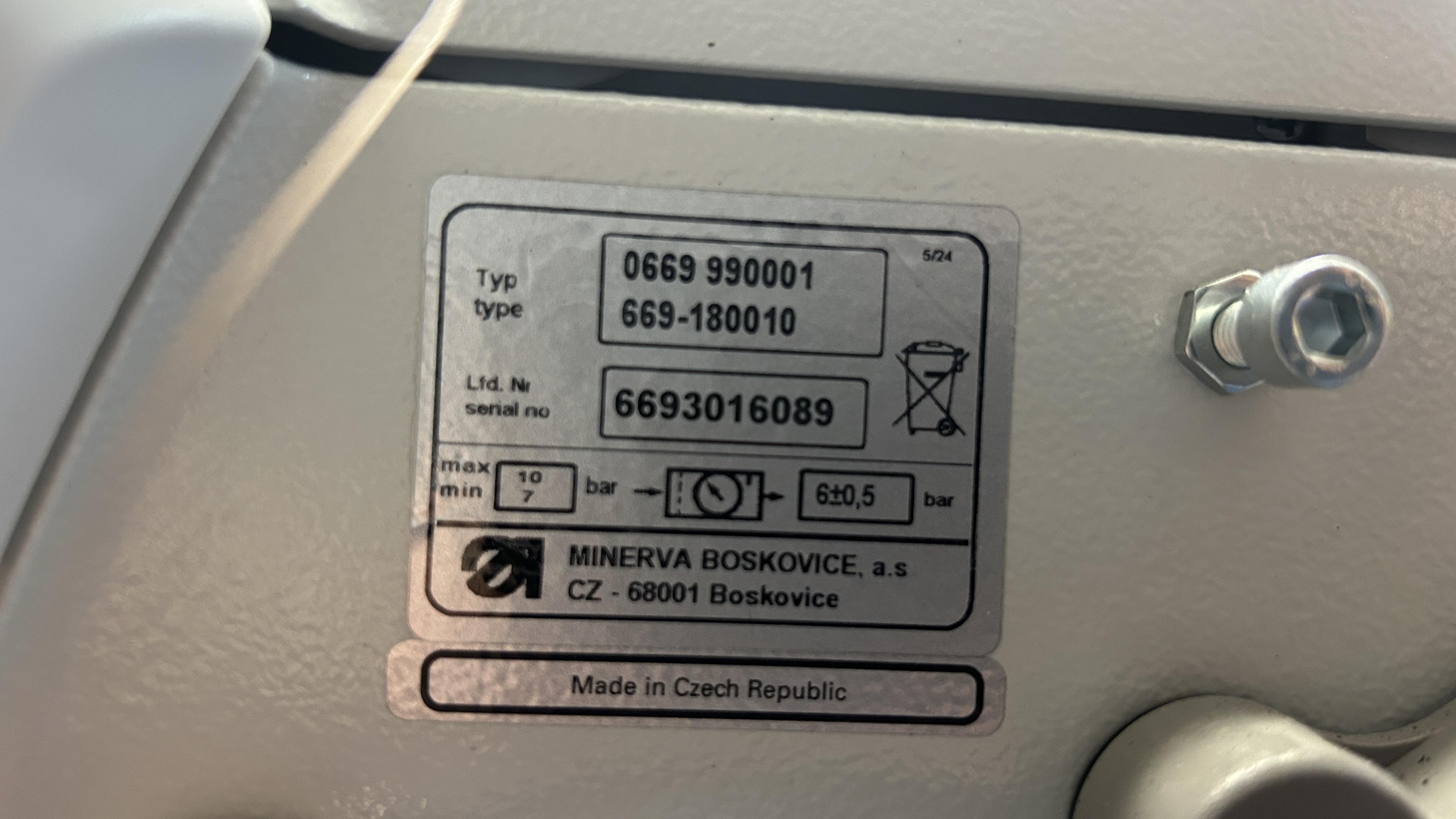

Hey Tom, appreciate your input. Actually, I have two Claes machines, which do the job perfectly. Specially on zippers. Besides zippers though I also do quite a bit of alterations to the calf area of the boots. I purchased an Adler 669 which sews perfectly however I think with a post bed walking foot I have more maneuverability. She sold the 669. And I’m now looking at the Techsew 850, and I was wondering if the Techsew is a reliable machine?

-

Is the techsew 860 a reliable leather sewing machine, has anybody used it? I will mostly be using it to work on horse riding boots.

-

three months ago, I purchased a brand new Adler 669 cylinder arm to using my Shoe Repair shop, wrong move, I actually needed a Post bed. Selling the Adler for $3500 had only. The machine is actually still brand new, altogether I use it for about three hours. if interested, call 978-771-0949. Or contact me through this site.

-

Hello, my name is Sam, I own a shoe Repair Shop in NH, I’m new to this informative site. I Recently purchased Adler 30-70, it’s in great condition, the only thing is , it only has an end wheel, and I can’t find a gear and shaft to move the end wheel to the front, anybody knows where I can find parts for this patcher? Much obliged.