waynebergman

Members-

Posts

26 -

Joined

-

Last visited

Profile Information

-

Location

BC Canada

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

waynebergman's Achievements

Member (2/4)

-

different approach to tippmann tension

waynebergman replied to waynebergman's topic in Leather Sewing Machines

My Groz-Beckert 794 160/23 LR point needles arrived today and if gives the stitch I was looking and hoping for with the 207 bonded nylon thread. Shown on the test strap of nat veg tan 2.4mm with a pre dyed black kip at .8mm glued to its back side. The saddle tan dye side is the top side of my stitch and the black, the back side. I experimented with lock stitching with the boss at the top right and on the top left I lock stitched by using my hand stitching needles to give a final saddle stitch treatment for the last two stitches to lock in the stitching. Not sure if the hand stitch locking is worth the effort but perhaps a little cleaner looking....... Question please - is it needed to burn the thread after trimming after the lock stitch? Any other tips appreciated for the lock stitching as the maching stitiching process is new to me. Overall I am happy with this boss tippmann, it will speed things up a lot for some projects but perhaps not used on everything I try. ......edit, my phots wont upload so not sure why, i have re resed them down to 1/2 mg each but no joy. I can try again perhaps another day........wayne -

different approach to tippmann tension

waynebergman replied to waynebergman's topic in Leather Sewing Machines

Thanks Alzila for the info on the "back side stitch". Its good to know the look of the back side can be helped like this. My main issue with how the machine stitching looks with this thicker thread is the "Back Stitching" to lock the stitch, not so much the back SIDE of the project. I am hoping the thinner thread 207 and the smaller needles will help with the bulkyness of the appearance gives for the needed back stitching. I feel my hand stitching is looking like I want but for the projects I tend to work on but I still want to clean up the look of the back stitch that my machine gives before using it on anything other than testing. Thanks again Alzila, if I stay with this machine and I dont go back to hand stitching I will get the tool you recomend to clean up the back side of the project.........wayne -

different approach to tippmann tension

waynebergman replied to waynebergman's topic in Leather Sewing Machines

Happy with this machine now, not super keen on how the locking back stitch looks with the heavy thread, I am used to a cleaner look that I get from the hand saddle stitching but for now I think the stitcher is dialed in for tension etc. -

different approach to tippmann tension

waynebergman replied to waynebergman's topic in Leather Sewing Machines

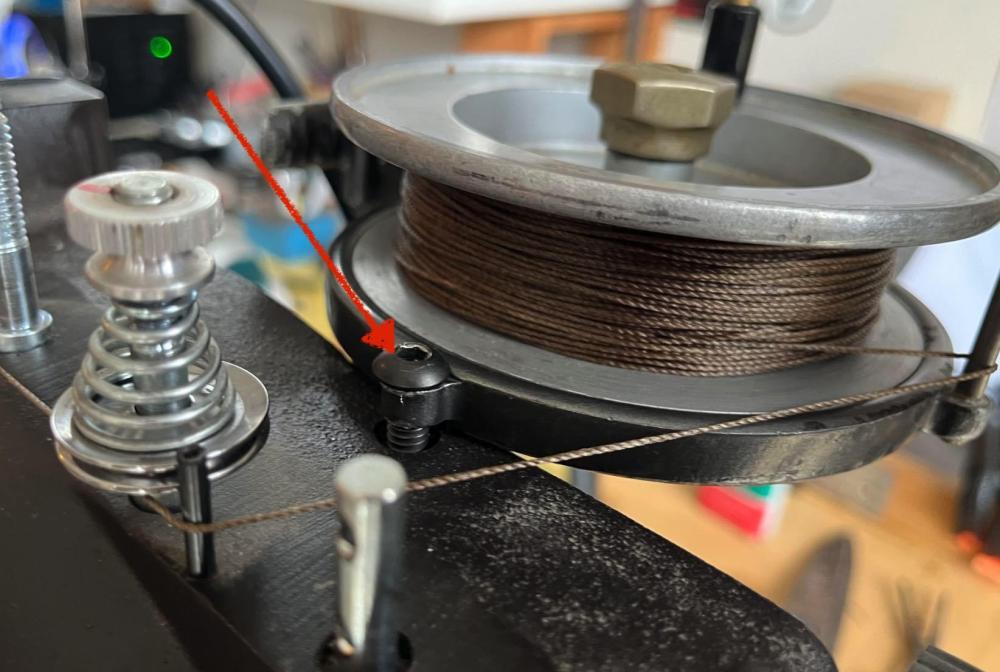

Thanks for the encouragment folks. A few photos here to show better how to install and the modell of the reel I used. Any reel should work as long as its got a good drag adjustment and you can turn off the clicking adjuster on the reel so its a steady drag . The one photo shows a red arrow - this is the alan head machine screw that holds the original thread spool plater on the machine. I took the thread holder off and just used this screw to attach my reel in place. I had to drill out the tab on my reel to a larger hole at 1/4" to accomodate the alan head machine screw, so pretty simple install really. The tippmann seconday tension washers are just kind of floating as shown sitting above the thread line in the photo not really doing anything for friction but when the line from the reel unwinds it may ride a little higher in the assembly so this sercondary washer could come in handy to keep the thread from slipping off the little post it rides on just before sliding under this seconndary tippmann tensioner. I hope this makes sense. Again I want to state I dont really even know how this machine works, but this tension hack seems to help. Still in the learning process of how to get this little machine to work in a repeatable fashion. The machine has only done 50 stitches or so since this modification so I will update further after I get my 207 thread and smaller needles, I may be getting ahead of my skis on this at this point but mostly sharing to see what the forum thinks and not so much telling others to try this. -

I have just bought a used tippmann boss machine. I took a chance on it as it was not working properly at time of purchase but it looked like low mileage and it I bought it from the original owner with reciept from 10 years or so back. This is my first machine and I wanted a machine that could come close to the look I am doing with hand stitching using a twist point chistle pricking system. I still want to source out a thiner bonded poly thread than the tan thread shown in the photos as this too thick for the look I want. I did find some twist needles shown in the photos also that give the twist pierce and angle the stitch so glad for this. I have another set of needles the same make but smaller to match the 207 or 277 thread I want to try. I really stuggled with the tensioning system and thought is was a poor design, also even tippman has conflicting instructions on how to thread through the primary and secondary tensioners. Shown in the photo is a work around that seems to give me better results. I have used a decent quality fishing reel and its drag setting to dial in what I feel is a better tension solution. I have bypassed three of the tippmann tensioners (tippmanns secondary tension looks like its being used but its really not doing anything). I feel this set up gives a clean pull on thread with out stressing the thread wrapping around what i feel are friction points that would be better off tensioned by the fishig reel instead of the thread (in my opinion). The photo of the black thread is my hand stitch efforts using T 69 and its the look I want with the angle of the stitch to its line, I am not there yet but sneeking up on it and hoping when my smaller gauage needles arrive with the thinner thread I can get closer. I thought I would share this for input from the forum. This is my first machine and my understanding of sewing machines are very limited but the fishing reel gives my a huge improvement on results so far. ...........wayne

-

I normally use natural veg tan leather and dye it myself. I have been given some very nice leather from a friend that was going to be used for a jacket and also a different batch for upolstering booths. I am not sure if the product I have been given is chrome tanned or what, it is already dyed of course. My question is if I use this gifted product as a lining for my veg tanned hand bags will it be compatable as in will it stretch differtly if a cement one piece full coverage to the other? ........thanks wayne

-

Thanks muchly................wayne

-

This machine called Relsew is of interest for sale. It appears to have servo and the seller says it is a walking foot. I will find out later exactly what kind of walking foot it is, hope to get the model number also later from seller but is anyone familiar with this make , seems like a good deal at 600 canadian?

-

update this machine was sold, missed by one day. He sold it for 600 cnd. Looks like he was high on his asking price by a long shot. KInd of funny I think he was one of these " I dont reply to is this still for sale?" good thing I didnt ask that as he forgot to delete the add. Note to grumpy sellers maybe buyers ask first for a reasonThis is becoming a real challenge to find a used machine as I am a ferry ride away from Vancouver so stuff gets snapped up before I get there but I am retired so no hurry really, just frustrating.Maybe with my location out in the middle of nowhere I need to buy new - I may need to sell one of my testacles to make this happen however......wayne

-

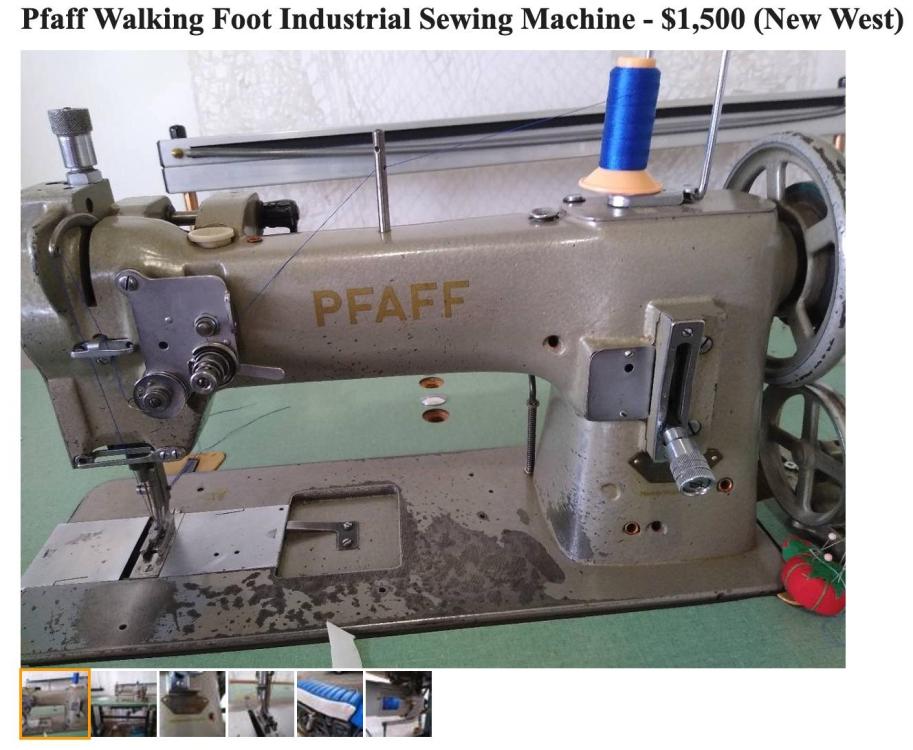

This machine looks to be priced a little high but not sure. It has a aftermarket Jomida clutch motor on it but I dont anything about this motor, I was assuming I will want to install a servo after I get it if I do buy this one. Photo attached shows the style of bags I currently hand stitch, I realize with out a cyl arm I will be still doing some hand stitching on one panel of the gusset assembly but I am ok with this. Can I ask please would this machine stitch up to 3/8" with tex 130 and I would like to use a twist leather point needle I think. I have never used a sewing machine before so trying to learn all I can before I pull the switch and buy. I think this machine is a true compound walking foot so this is good. Thanks so much for the help so far , I am learning a lot from you all.......wayne

-

I see a Taking TK 2973 for sale, machine only at 1300 cnd. I guess these are like the singer 29k70 . Can anyone tell me please if this patcher will leave marks on either side of veg tan leather? I am guessing it will but wanting to check with others that may have used this machine. Have these modern clones any better or worse than the origianl old timer 29k models? Thanks ....wayne

-

yes great advise folks and thanks, I was kind of thinking this myself. I am leaning now towards a consew 226 complete with servo , table and working and looks in very very nice condition. Price is 800 candian but someone else has first right of refusal on it. If its still available for me next week I plan to buy it. I was able to dig around on this forum for past posts on this machine to realize the thread size and leather thickness is going to be just fine for my needs. Its not a cyl arm but will work and my budget is 1000 cnd max so I think this consew may do the trick. Thanks again everyone for all the tips and help over the last few months..........wayne

-

I am looking at cyl walking foot for sale that I am not too sure on but it looks promising. I noticed years ago on this site a member inquired about this same model Tecmic LS3-202 not much was uncovered in that thread. Not sure if this machine is a clone of something else or what parts would be interchangable from other machines if needed. The machine is supposed to be in good condition. Wondering if anyone has any info on this one for me please? The past oldr thread implies it will max out at tex 40 which is way too thin for what I want. I would hope this machine will sew 5/16" veg tan leather with a tex 135 thread but wondering if anyone has any more info on this unit in particular the thread thickness for succes on 1/4" veg tan? The machine is listed for 600 usa dollars but no table or motor, i would mount it myself on my bench and put a servo set up on it I think. Any insight much appreciated........thanks in advance Wayne. link to old thread here

-

Thanks Wiz for the helpful advise . The journey will continue...wayne

-

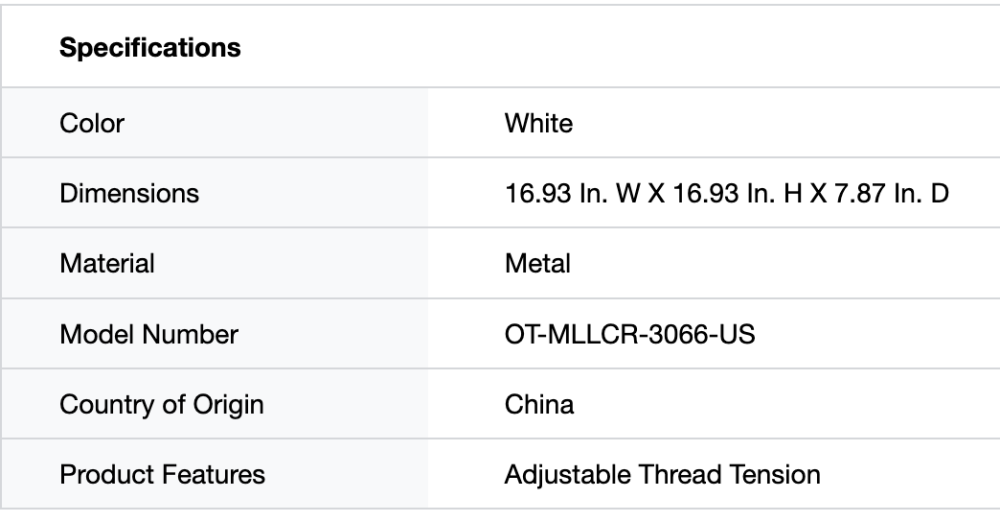

Thanks Wiz, I checked out the site web address and it seems ligit. Canadian end of it and BedBath for sure. ONe thing is kind of wierd is the size of the machine, it almost looks small in this photo and specs say less than 8" tall , I wonder whats up with this, are this patchers made in this super small size?