Farmfield

-

Content Count

24 -

Joined

-

Last visited

Posts posted by Farmfield

-

-

1 hour ago, CowboyBob said:Tilt the machine back & on the middle shaft (the one that runs the hook) you see a large gear,loosen the 2-set screws just 1/2 a turn & tap the gear to the right 2-3mm,should fix it.

What exactly does that do? It feels like that would change the timing..?

-

-

So let's start off with me being pretty familiar with industrial sewing machine mechanics, but, and though the Singer 111 design is my absolute favorite, it's also a design I'm just not very good with, servicing...

Now I got myself a noisy Juki 563. As far as I can tell the main issues are; a stuttery noise in the front, like the gears are too tight, and there's a "knobby" sound from the timing belt.

But the shape of the gears and the belt seems fine, so I'm guessing it's all a question of adjustment.

There's also a bit of a howl at faster speeds - something I've run across with several Juki 562/563's before - but never with Singer 111..? Anyone know why that is?

I'm kinda thinking it might be the rubber belt vs the cleated belt in the Singer 111's that might be a factor. Not cheap to get a NOS cleated belt, though, but if it's that, I might put up the $75 for one - especially to get away from that knobby sound.

And I've checked around a bit and watched some videos, but I haven't found anything about these specific problems. So yeah, any tips, links to good Singer 111/Juki 56x service resources, videos, etc, on this stuff would be much appreciated.

Image for attention. Cheers. :D

-

It wasn't the hook it was the needle, and I got it sorted after some trickery. I can't seem to edit the original post, though...

And yeah, great patchers. I've sold two (including this one today) and both has been great, after some messing about, getting them to sew well again.

-

So I'm in need for a new shuttle for a Claes RPX-2. (same as for Claes 200-2 and Claes 20)

I messaged both Claes in Germany and some local suppliers, but it seems these are very pricey, so I thought I'd ask if anyone knows if any of the Singer 29k subclasses has a compatible shuttle? That should likely be way cheaper...

And I'm in Sweden, so any tips on where to get one should preferable be within EU to get away from import charges, etc...

-

Just a question, is the 200 or RPX the never model?

-

3 minutes ago, shoepatcher said:Needles available on line or from Toledo Sewing. You need to determine the class first. The 1 and 2 use system 81 needles, the 3 uses system 88. Can we see a pic of the machine?

glenn

It's 81. And I haven't found anyone in Europe offering 81 needles aside from size 90 which is a bit to small to be very useful.

And here are some pictures and a demo video.

-

Just now, shoepatcher said:Is there any numbers on the cover on the horn? It would either be an 81 0r 88

glenn

Nadel 81.

Good you brought this up. Any tips on replacement needles? As in, is there a more common needle close enough in size to be usable? I don't have any 81 needles so running it with a 135x17 mounted low right now. Sews like a dream, but pretty far from an optimal solution, haha...

-

2 minutes ago, Constabulary said:sounds like a 200-1

Bobbin diameter is 14-15mm.

-

3 minutes ago, Constabulary said:do you have a 200-1, 200-2 or 200-3 (lager prefix = lager hook)

CLAES is still making the bobbins so you should be able to get them from shoe machine dealers or other sewing machine dealers. if not check with CLAES, I once visited the plant and bought some spare straight from them. Nice folks, really! But shipping from Germany to to Sweden probably is a deal killer.

No clue on the subclass, I haven't found any markings on it, but it's one of the smallest bobbins I ever seen, though a bit taller than the Singer 29 ones, I think.

As for shipping, this machine was imported from Germany through Poland on a pallet with 3 other leather machines, haha, so shipping is a non issue. It was bought for resale.

-

7 minutes ago, Constabulary said:10mm is not the stitch length. Rather consider it just as a scale. From my experience the model 200 (which you have) makes 6mm Stitches at max.

Sounds about what I get, so it is what it is, then.

Any ideas where to get bobbins and/or bobbin case for this model?

Else I got some milling, lathe work and soldering ahead of me...

-

3 minutes ago, shoepatcher said:pics of the machine?

glenn

Here:

https://photos.app.goo.gl/69e1qLTaMdGQ444J8

And I made a leather block for the stitch adjuster, though not in these pictures.

Only thing is max stitch length seems to be 5mm while the stitch length adjuster is between 0 and 10mm. Not sure why it maxes out at 5 - even with the leather block removed, thus allowing the accentric thingie to its lowest position...

-

On 10/28/2022 at 12:11 AM, Constabulary said:What CLAES model do you have? From the 200 / RPX onward there is a leather (or later) plastic block under the stitch length adjuster, make sure it is is present. If not feeding make sure the "Transportkeil" (see parts list) is not poped out of place. It should "hang" in the rim of the needle bar bushing in which the needle bar is going up and down in.

Just notice the the EDIT so forget it.

Yeah, noticed the block was missing, made one a so now it works. :D

-

Edit: Solved. It looks like I'm missing some kinda rubber spacer thingie on the back.

I need to understand the stitch length adjuster on the Claes patcher. On the one I have here I can only conclude it doesn't work, but I haven't been able to figure out how it works, mechanically, and it's hard to fix what I don't understand.

-

19 hours ago, DrmCa said:If you've gone through putting a new needle in, checking the thread path for burrs and missed through holes, ensuring the correct tension top and bottom, then the thread is the only thing left to blame. We use the thread like yours for topstitching jeans, and all of the poly or nylon leather threads that I have has about 2x slower twist. This is all that jumps out on me.

Yeah, I'm ready to give up on it for the Pfaff 545. It's just annoying as I have so much if it, but I just can't spend more time fighting this.

-

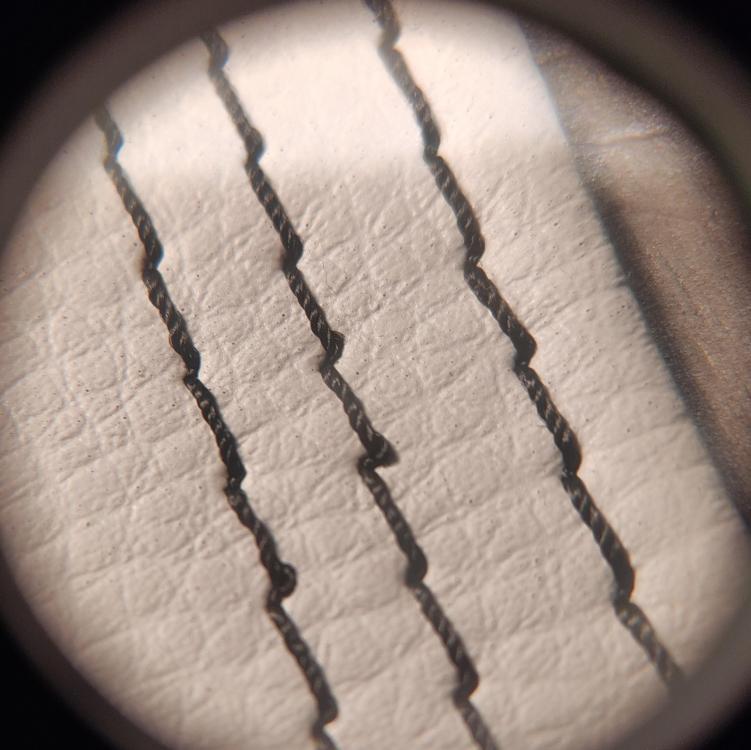

31 minutes ago, DrmCa said:Just look at that thread in your pictures. It has a very fast twist unlike threads you normally buy for leather machines. The purpose of this thread is probably to sew modern stretchy denim.

Btw, thread in all forms, beyond the domestic stuff, is really hard to source in Sweden. We really don't have a sewing industry here, so availability is very limited and what's available is very expensive.

-

8 minutes ago, DrmCa said:Just look at that thread in your pictures. It has a very fast twist unlike threads you normally buy for leather machines. The purpose of this thread is probably to sew modern stretchy denim.

I'm not that read up on thread, to be honest, but I get what you mean.

That being said, comparing it to Gutermann thread I use without problem in the 545, the PolyArt thread isn't more elastic - but it's way more keen to split/unwind than the Gütermann thread is.

You'd also think that, if that was the problem, it would differ a lot through the range of tension, right? Lower or higher overall tension (as in, both bottom and top) would make a big difference, and it doesn't...

And funny enough, this is the most popular heavy thread offered by our biggest industrial sewing machine supplier here and they've carried this product for over 10 years. If this was a common issue, you'd think they would write something on their info page on it, but no...

So friggin baffling, this.

-

1 hour ago, Constabulary said:are you using a leather needle instead round point - maybe?

No, this is vinyl and sewn with ballpoint needles. But I get this issue with other materials as well.

-

15 hours ago, DrmCa said:It's got a fast twist for sure. I wonder if it affects the stitching because this thread is so stretchy.

OK, "fast twist", that's a thing?

One thought I've had is, as the bigger bobbin means the machine has to pull out and back i bit more thread than a machine with small bobbin. Mayby it's as simple as the problem rises from that slight difference..?

-

15 hours ago, kgg said:Have you checked the top tension discs for wear?

kgg

Yeah, I switched them to new ones. No difference.

That's what fascinates me the most, nothing I've tried has really made a difference, haha...

-

54 minutes ago, kgg said:Looking at Lial website (en.lial.biz/thread-polyart-20-1500m) in their specs it lists the thread as #20 but lists it as Tex 154 which would be closer to a #15 (V207)thread rather then a #20 (V138) which may have to do with it being a looser polyester thread.

kgg

It's loose, alright, very keen to untangling...

The thing is, this is a big seller since a decade at one of Sweden biggest industrial sewing suppliers, I don't think it would he if it was generally problematic - and it's worked fine with everything but my 545 - I'm just trying to figure out why it doesn't work in the Pfaff. Even if I can solve it, it's good to know what's causing the issue...

-

So I got 10 unused spools of PolyArt 20 thread with a machine I bought, perfect colors for what I do, but for some reason I just can't get it to work with my Pfaff 545 - I get these weird kinks...

I've tested this thread with a Durkopp 239, A Juki 562 and a Singer 111G156, and it works without problems on all of them, no problem getting great stitches.

And this Pfaff 545 works perfectly with all thread I tested accept this PolyArt thread.

So I tested a bunch of needle sizes, I've gone through the whole range of bottom and top tension, I played with the hook timing, I played with the needle position, I played with the bobbin case opener timing, I deburred the slot in the needle plate, it feels like I tried everything, but I just can't get good stitches with the PolyArt thread on the 545...

It's driving me nuts - I just can't understand why it works in the other triple feed machines with horizontal bobbin but not with my Pfaff...

And yeah, the top tension is a bit to high in the picture, but even with balanced or too low top tension, overall too low or too high tension, I still get these kinks in the thread...

-

On 11/9/2019 at 9:25 PM, DanishMan said:I changed the hook saddle and the bobbin case (including bobbin case opener).

Ok, so I'm hearing this conversion isn't very straightforward at all, haha, so I'd love to get a bit more information on the procedure as the hook assembly on my 145 is a tad rattly and if I'm replacing it, I might as well go for the 545 assembly and bobbin case - if it's not too much work switching them out...

Juki 562, top thread gets caught in bobbin tension slit

in Leather Sewing Machines

Posted · Report reply

Hmm, ok, so it's a top-bottom sync issue...

And I could move it 1-2mm, then it started binding up, and it's better, but not perfect.

I think the bobbin case might be damaged, the edge on the slit is very sharp, almost protruding, so I'll get some fine sandpaper and soften that transition, I bet that'll sort the issue completely.

I really appreciate the help. :D