RaSk

Members-

Posts

6 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

RaSk's Achievements

New Member (1/4)

-

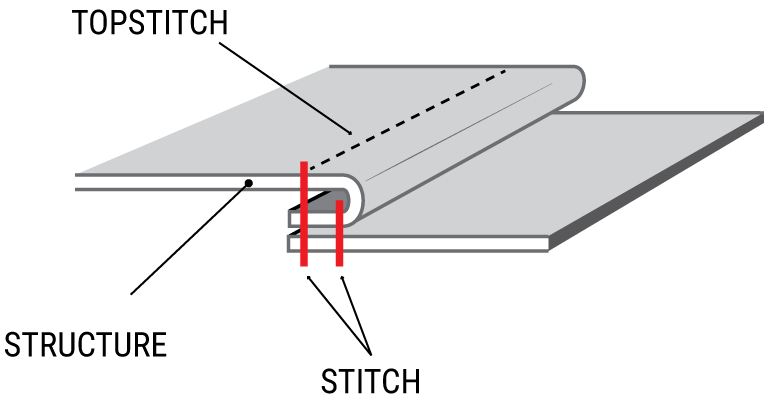

Hi, After reading on the subject, including various posts here, I'm a bit confused about the pros & cons of double vs triple feed. I understand that one of the big differences is that triple feed usually has a smoother presser foot that prevents damage on leather. I guess that the needle helping to drag the material allows a softer grip on the pair of feet. But on the other hand double feed seems to integrate newer technologies (like computerized stitch length) and is much cheaper. As a sewing beginner, one of my issues with my current triple feed machine is when sewing on top of quick-changing thicknesses, like topstitching at the intersection of 3 pieces where it goes from 3 layers to up to 8. One of the benefits of double feed and drawbacks of triple feed mentioned by Sailrite is this "bump" issue with compound/triple feed. But one other manufacturer that offers both mentions the opposite on their brochure when choosing between both models (2030 vs 2060). I'm not using leather yet, so I'm considering buying a double feed to complete my set of machines. Would it solve my problem with bumps? Any other drawbacks to consider regarding double feed for upholstery? Best regards, Alex

-

Thanks all of you for your answers! I have already a lot to work on and digesting all the information. I was already wondering on this forum when I started this new passion and searching on Google. Very glad to see it's so active and people are so kind! I think I'll do a separate topic regarding the edge-guide feet as it's also linked to a "clone machine" question.

-

I've sent some pictures yesterday. With the longest stitch setting, I cannot succeed to do stitches longer than 3 or 4 mm with the "edge guide presser foot" (it's not an edge guide like you sent, it's a presser foot with a guide in it). I have a similar drop-down guide, not with a wheel but still a similar idea. The issue is for the type of seam I'm doing I'm not sure it's the ideal tool as it will have to lay on the material as well. I'll probably have to take a picture so you can see what I'm talking about.

-

What do you mean by edge? These were the only feet provided with the machine. Regarding changing the handwheel pulley, I've read on this forum that it was not the most recommended solutions for several reasons. What are the pros & cons? Or why did you choose this over other options? I've checked it is firmly held down at almost every moment of the cycle. There is a very slight position where the material can slip (pulling it with a lot of force), it is just before the needle penetrates the material when it switches between foot. Overall it seems to be holding very firmly. Should I care/try to tune it because of this very slight position? I can do a video if you want. (Fun fact: Your nickname is almost like mine, my favorite number is 9 and I have a Malinois -that stays at my parent's house-. ) I've tried tweaking every parameter of the servo motor using this manual The V setting for max speed just limit the max speed/RPM, no effect on low speed. I've already chosen the lowest settings: 5. The M setting for synchronizer mode as said previously has only a small effect on the final needle position (when stopping) Z/L settings seem to be only a technician setting that impacts the V setting, so also no effect on low speed C setting for torque, I haven't noticed any significant change N low-speed setting (positioning speed according to manual) also has no significant effect I've read here on the forum that it's common that sellers don't understand the need for speed reduction as 99% of the market wants speed. I asked for speed reduction, he got me speed limiting, not exactly what I needed. As I said previously, I'd rather not change the whole motor for now. Buying an EFKA at 800$ for a machine that cost me 600$ (with a new servo motor) doesn't make a lot of sense to me and I do have not a budget for it yet. Thanks for joining in! I was reading some of your posts yesterday before bed time, glad to see you here :D Yep I thought it was maybe too many questions. As we've focused on machine, I'll probably do another thread in another section for the patterning/sewing questions. You're correct, I just checked it is a 75mm pulley and it starts with "02" on the display so I guess it means 200 RPM. I've tried unscrewing the pulley on the servo motor to check the shaft, but the pulley turns... Sorry I'm a real newbie on those topics Should I turn on the motor? Thanks for the SIECK suggestion, it seems like a good option. Reading a lot from this forum, I've found 3 solutions regarding pulleys: - hand wheel pulley for a larger one - servo motor pulley for a smaller one (I've seen even some 3D printed ones!) - speed reducer I've also checked it's a 13mm shaft for the JACK motor. I guess with those conditions DIY speed reducer or 3D printed servo motor pulley are the easiest/cheapest options? I haven't seen long-term feedback regarding 3D printed pulleys, are they good?

-

Hey guys! Thanks for all the answers. I've tried disabling the needle positioner (the M0 parameter, M1 is "synchro activated") but it doesn't seem to have much effect besides stopping less accurately the needle. My guess is that the needle positioner, even disabled on the servo motor, has still a mechanical effect on the shaft/pulley, but it's a newbie guess. Here's a picture of the difference in stitch length: on the right max length with regular foot assembly and on the left various tries with the edge guide presser foot (reducing loading, reducing spring tension, etc.). Now that you've pointed out, I've noticed the foot assembly is not aligned with the feed dogs for transport...... Is that it?! Also my regular foot assembly has teeth underneath, and the edge guide presser foot has none. Thanks for your reply. So you would suggest a bigger pulley and keeping the needle positioner? I've measured my current pulley I think it's between 70 and 80mm, so I'd guess 75mm. Thanks, makes total sense for the bobbin suggestion! I think I'll keep it simple and use the same thread for both. After watching some videos on pulley reducer it seems that it would do the trick. Regarding the calculator I think this is the one: https://www.blocklayer.com/pulley-belteng.aspx Are there standard dimensions I can/should use? Regarding the stitching I'm doing, this is what I called a "felled seam" but I'm not sure it's the correct term. Thanks. While doing my pressure foot testing, I've almost unscrewed completely the pressure screw and it's a bit better now. My motor is still almost completely new so I guess I'll go for a speed reducer pulley solution for now, but thanks for the suggestion. I've recorded this video of what happens. The worst part is sometimes when I'm trying to do 1 stitch, it does 3 or 4 very quickly. I first thought it was my foot sensitivity issue, that I wasn't used to it. But I've tried manually, like adding grams of force, but still almost impossible to do 1 stitch.

-

Hey! I'm Alex from France, I've discovered a new passion for upholstery and I want to transform this hobby into a business as soon as possible. My goal is to make upholstery for cars and motorbikes. I'm using only vinyl fabric for now but I hope someday to start using real leather! I have watched probably more than a dozen hours of YouTube videos (if Cechaflo is here, you're a god!), and bought the Lucky Needle course. I've also got probably 30+ hours of sewing and 30 hours of patterning experience for now. I've got a lot of questions regarding upholstery, sewing, and sewing machine, to avoid separate topics I decided to post them all here (my biggest current pain is slow stitching). Machine - I bought a Durkopp 239, it's a walking foot single needle. Was it a good choice? I can't really get my money back and I also don't understand the differences between all those walking foot machines. Slow stitching - I have a Juki servo motor (JK-513-A) and a needle positioner. My current issue is that I can't do "less than 1 stitch point", it is binary: needle up or needle down. But I can't do an approach using my foot like Cechaflo does in a lot of his videos. Have I been tricked by the vendor who told me the servo motor was the best for my use? I tried using the M0 parameter (no synchro) but I still can't get it to work as I expect. Now he is telling me that I should buy an EFKA servo motor that is more expensive than the machine itself. I've seen Uwe's video with a thumb controller, it seems amazing, but can I do it with my current brushless motor? My first guess is that the needle positioner itself his blocking the wheel in up/down position, but the vendor seems to insist that it's not the case. Presser foot lever - My foot lever behind the machine is very hard. Is there something wrong? It is a bit easier when I use my knee on the "under the table lever", but if I release it it's like a 10kg force that seems to be realeased. Bobbin thread - I've read around here and seen on some videos, that it's better to use the same thread for the needle and the bobbin. I've also heard that you can use a thinner thread for the bobbin and it will make a better seam aspect. What is your experience regarding that last statement? And what are the downsides/benefits of both solutions? "Reversible" sewing - As I'm borrowing the small CNC from my wife (Cameo 4 Pro), I was trying to digitize some patterns and then draw seam lines & cut on the backside of the vinyl with some nice results. Following the previous question, if I use the same thread for the bobbin, is there a world where I can sew from the backside of the vinyl? Mostly for a purely decorative seam, like drawing something on the back and stitching it from the "back" side. My understanding of lockstitch makes me think it is possible. Felled seams - I don't know the correct terms for this question, but I think I do 99% of the time "felled seams". I'm doing small stitches for the "inside" seam and as long as I can in the "decorative" / strengthening seam. I have some questions: is it normal that the "decorative stitch" seems so hard? Would a bigger foot help me, a bulky one, like the one that comes with the Sailrite Ultrafeed? My current foot seems thin on the right side, and I'm probably sewing too close to the seam as I can see the "inside" seam a bit appearing. Is this the case? How can I improve my felled seam? Open seams - I've seen some designs done with only "open seam" or a mix of them, basically skipping the decorative seam. They seem nice in some designs, but what are the downsides of doing that? Presser foot guide - I've also bought (by recommendation of the vendor) a presser foot with an edge guide, exactly this one but 3 times more expensive, to do the decorative seam mentioned above, my issue is that it does small stitches. I've tried reducing the spring tension but still not very effective. It's probably not a good idea to use it for felled seams, is it? Curves - I've been improving my curves skills but I still have a lot of difficulty with very sharp curves (like a 90° angle in 3cm / 1,2 in). I can do them "properly" (read "acceptable") maybe 1 out of 4 or 5 times, including a lot of relief notches and manual sewing (hand on the wheel, as I can't do approach, see question 2). Is this even possible? Or should I change my designs? Any tips? I've tried stapling but it's not really compatible with stress relief notches. Patterning notches - I try to add as many notches as I can (maybe too much), but in general, do you recommend adding notches inside the curves and/or before/after? Curves on curvature - When I do patterning, I'll have two pieces (let's say A and B ), but sometimes I end up with: A straight + B curved, A curved + B curved in the same direction, or worse A curved + B curved but in opposite direction. I guess that it comes from the curvature of the model (like concave or convex parts), but I still can't get my head around it. Am I doing something wrong? Stress relief notches - Following the last question, I try to use "tension" relief notches (only small perpendicular cuts) as it's easier for me to do and foresee. I still rarely use "compression" relief notches (triangles to have less material and avoid wobbly material), should I use them more? In which case? For the "tension" relief notches, I find it easier to cut a lot of them thinly (like 2mm), it seems to help but the downside is that I can't use staples. Is there any reason I shouldn't do this (cutting thin tension relief notches)? Sorry for the long post, here's a baguette and a glass of wine for your time: (oops can't include emoji, but the intention is there <3 ) Merci! Alex