UncleSam

Members-

Posts

16 -

Joined

-

Last visited

Profile Information

-

Location

Perry, NY

-

Interests

Horses and Metalwork

LW Info

-

Leatherwork Specialty

Horse blanket repair and Medical applications for horses

-

Interested in learning about

machines

-

How did you find leatherworker.net?

former User

UncleSam's Achievements

Member (2/4)

-

question on older Adler cylinder arm machine

UncleSam replied to UncleSam's topic in Leather Sewing Machines

I talked to the lady I work for today, and she agrees that the machine, for me anyway, is not going to work financially. For her, she wants a flatbed, no cylinder or post or removable flat table, something she can use for medium or thinner leathers. They have a large heavy at the shop, so something like a smaller, flat bed would be the right machine. She would be thinking of quick sale or trade or even trade with payments on machine she needs. It is not doing anything for her at the moment in the shop. Ebay/Craigslist at this point is not an option. Any enquiries can be made through me here, or you can contact her directly. Right now the shop is flooded with year end work on saddles, bespoke items and inventory for years end. Any help would be really appreciated on this. Regards, US -

question on older Adler cylinder arm machine

UncleSam replied to UncleSam's topic in Leather Sewing Machines

Thank you Glenn for the great information. It does not have air lift, or back tack I do tknow that. I'll call Durkopp/Adler today. US -

question on older Adler cylinder arm machine

UncleSam replied to UncleSam's topic in Leather Sewing Machines

Thank you Michiel for the link. US -

question on older Adler cylinder arm machine

UncleSam replied to UncleSam's topic in Leather Sewing Machines

My thoughts exactly. So many variables, and since I've not heard back from the man who works on my Brother (usually once a year because after 18 years of him working on it, he taught me so much about the machine, he just does a tune up once every 12-18 months.) I really want his input, since he also services the other machines at the place where this one is. The man down the road from me gave me basically the same info re: costs and availability as you did. I am not one to chase unicorns, so a good used refurbished would be more of what I am looking for. US -

question on older Adler cylinder arm machine

UncleSam replied to UncleSam's topic in Leather Sewing Machines

Thank you for forwarding this. Unfortunately I don't speak German, so did translate to English which would help me better understand how this works I printed out all the pages which will be helpful, but it's mostly instructional; how to thread, tension, etc. I need the parts catalog for this model to see which timing belt is used. When I went back to available PDF downloads, the model 169 is not listed and there are 232 pages of parts, just for one model alone, so if anyone can help me decipher how to get to the next step, I'd be very grateful. US -

question on older Adler cylinder arm machine

UncleSam replied to UncleSam's topic in Leather Sewing Machines

Mostly medium weight messenger bags and repairing stitching that I don't do by hand. If I need to repair something with harness leather (last year I made new covers for farm tractor doors with vinyl and plastic windows for my hay man. I used my friends heavy duty post machine for that. I can go down there (about an hour) and use her machines, just was thinking of winter driving/roads etc. I'm sure I can live without it, just sometimes gives my hand a rest from saddle stitching. US -

Felt Pad for Hernia after colic surgery on yearling

UncleSam replied to UncleSam's topic in Member Gallery

Yes, people who cannot properly saddle or understand how tack fits don't last long if at all, down here. I learned starting back in 1952 when I had to stand on a step stool to tack up a horse. That and time in the UK and the BHS, set us up right. (My father said: Learn and absorb it all, its a long swim across the pond. US -

question on older Adler cylinder arm machine

UncleSam replied to UncleSam's topic in Leather Sewing Machines

By the way KGG, tell me about your China patcher . US -

question on older Adler cylinder arm machine

UncleSam replied to UncleSam's topic in Leather Sewing Machines

Hi KGG, it took me a while to get back to the photos of the cylinder arm Durkopp. That inside belt is the timing belt, but trying to find the model (not the serial number) number has proved difficult. Seems as though they are available (depending on model number) from Moscow or Ukraine via China for about $30 +- Takes a few months to arrive and then you have to find a brave soul to install them which is quite costly. The one from Russia is nylon with copper bands but don't know if it's for which model of cylinder arm. Here are the photos I got on Friday- Thanks so much for looking KGG, I've contacted several people around my area (between Buffalo and Rochester) and am still trying to find out more-like if it can be fixed. US -

Felt Pad for Hernia after colic surgery on yearling

UncleSam replied to UncleSam's topic in Member Gallery

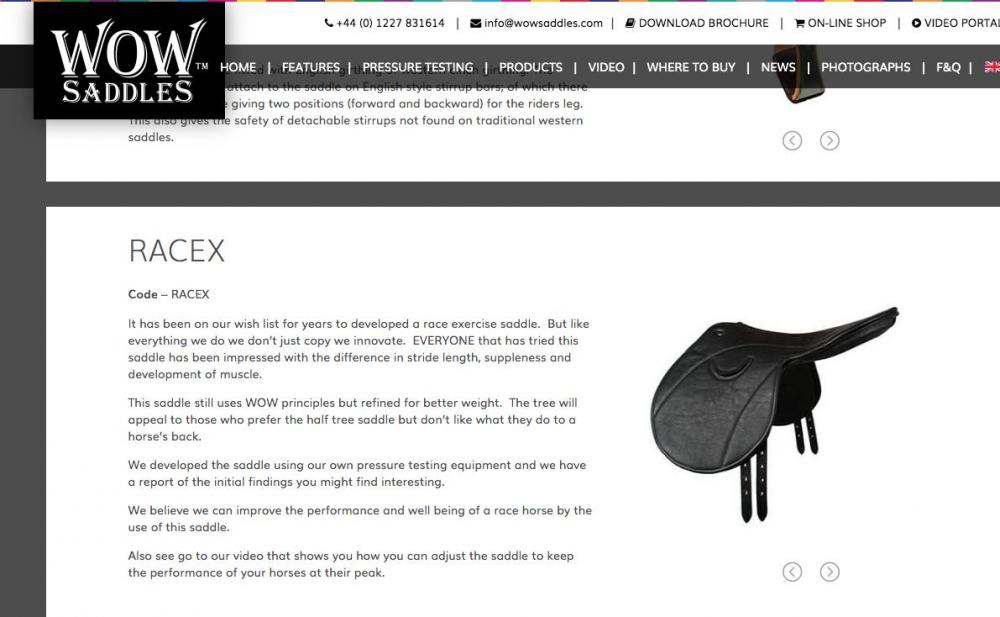

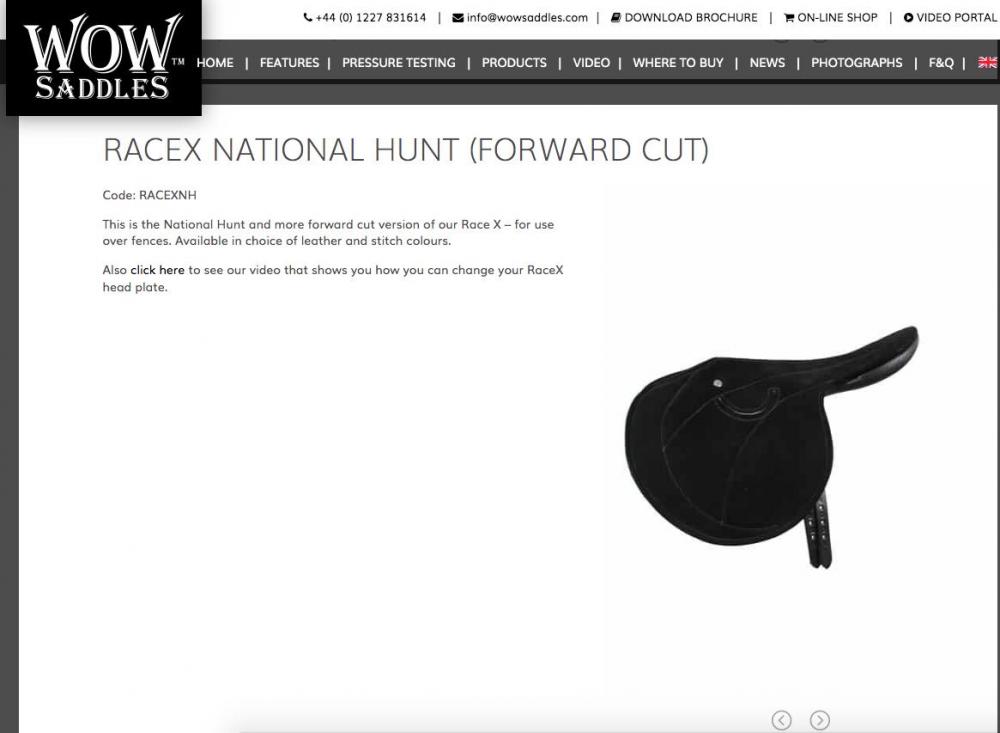

I thought you might find these interesting. The first one is there exercise saddle, the second NHR for chasers. They address the issue of correct head plates and proper placement (shown in the NHR explanation for the head plate. -

Felt Pad for Hernia after colic surgery on yearling

UncleSam replied to UncleSam's topic in Member Gallery

Actually, I did remark on this when I first went there, but at that time they had a regular saddle pad under the appliance which wasn't good enough, because there was no curve from behind the withers to not allow it to flatten down on the top. The primary objective was to heal the hernia, and the shape form of the under pad was not addressed. These are TB mostly for grass racing and steeplechases. I've had my share of them I've rehabbed to event horses, and even the one I have now, at some point had a bad fistula situation from an ill fitting saddle. I have my x-c jumping saddle from first thought Equine in Kent, made specifically to address various body sizes, so I'm able to have the correct panels and seat and can adjust the air in the panels. My flaps were the only original bits I didn't change, even the head plate was wonderful for this new horse of mine. They have been also making the racing saddles which have addressed a number of issues. Got to run out and finish getting Sams hay drained and his dinner fed, he has me on a strict schedule. -

Felt Pad for Hernia after colic surgery on yearling

UncleSam replied to UncleSam's topic in Member Gallery

He was only so young when he coliced, and spent 3 months at the Vet hospital at Cornell, then he's now 6 weeks in his stall and feeling very sore. The vet was very happy with the pad, but since he has developed soring on his withers and spine, we cannot try it on him until that clears up. US -

question on older Adler cylinder arm machine

UncleSam replied to UncleSam's topic in Leather Sewing Machines

knew I had something wrong They have the manuals Except for the leather belt they were using it just not much since they got the Weaver one which is larger. I'm back at work on Friday I'll get more information from the manuals then. kThanks! I will check the plate on the machine Friday and get more information. Thank you, US -

question on older Adler cylinder arm machine

UncleSam replied to UncleSam's topic in Leather Sewing Machines

Thank you so much for that information KGG. The dryer socket I have is 3 prong Here are two pictures of the machine. -

I have a chance to purchase an older Adler cylinder arm machine for items that I cannot use my Brother LS2-F52A for due to bulkiness of pieces. It has a leather belt that is getting replaced, and also I would have to supply a 3 prong HD 50 amp plug. It comes with bobbins, bobbin case, needles and 3 cones of HD harness thread and original paperwork/manual. My question is, can I use the HD socket from my clothes dryer? I removed the dryer 2 years ago, and left the plug and receptacle in place in case I ever got another dryer. I have a solid safe 220 service here at the farm. The Adler is in a saddle shop and has 3 other HD machines for harness and saddles and they don't need this one. I work there a few days a week, and had expressed an interest in it, so the owners are getting the leather belt replaced. Any thoughts on the older Duerkopp-Adler machines? sorry photo is so small, will get better photo and serial number today while at work. Uncle Sam