ClaudioBravo

Members-

Posts

12 -

Joined

-

Last visited

Profile Information

-

Location

Eastern Europe

-

Interests

Design, Computers, Technology, Graphic Design, Photography, Hi-Fi, Automotive

LW Info

-

Leatherwork Specialty

Still learning

-

Interested in learning about

Leather Jacket

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

ClaudioBravo's Achievements

Member (2/4)

-

I would like to hear from you... what are you think?? I'm messing a lot to dial in a proper top and a bottom, bobbin tension! After a lot of trial and error, those are my best bet. First, I'm not sure if I had proper cutting needle point, maybe my stitch would be "deeper"... also, I can't have enough bobbin tension with my light and medium Lockstitch Juki DDLS 9000B-SS bobbin. So I guess I will definitely have to buy a new machine just for leather sewing??

-

After a lot of trouble matching the thread size of the leather jacket, I would like to clone it, this is my best bet. First my setup: Lockstich Juki DDL9000B-SS, Top thread polyester Generic 20/3 (#138) Tex 15 Bobin thread AMAN Serafil 30/3 (#92) Tex 90 Needle 18/110 with R point style, without cutting effect. I wasn't able to find needle for my DP x 5 system with cutting point right now! Lamb Nappa leather, brown is a really thin one and black is a little bit thicker.

-

Last year, I wanted to complement our line of evening dresses with women's bags-purses. After a dozen You Tube videos from Louis Vuitton, Hermes, Chanel and Dior, it was clear to me that everyone uses cylindrical machines with compound drive for the bags and there was no dilemma what to buy. I chose Durkopp Adler 669. One local dealer asked me for 3100€ + VAT and the other for 3300€ + VAT, but with a binder variant. And then I discovered that for that money I only get the ECO variant, so pure mechanics. For "electronics", in fact a pneumatic machine, they asked me twice, almost 6600 € + VAT When I went to both companies and looked at a dozen new Durkopp Adler machines, I saw that they were all made in the Czech Republic. And honestly, I didn't like giving so much money for a product that is not "made in Germany" and which in 2021 will be powered by pneumatics (must have compressed air on site) instead with electromagnetic or servo motors! Then I surveyed my customers and they mostly told me that they are not overly interested in unbranded bags and for now I have given up on that idea! So I'm waiting for Jack to introduce a compound drive cylindrical machine to buy it, to have it just in case. p.s. Looking at Minerva and the Dutch Global website, I saw that the machines are made exactly the same design and look like Durkopp Adler, only under the name Minerva and Global and I would say they use a slightly different base color for the machine body, while everything else is the same ... I don't know where those machines are sold, but the M-type is definitely not a real Durkopp Adler!

-

Hey, yes, I just browse a Part Book for Adler 669 and really never thought that it use belts instead of solid shaft. Both Pfaff 335 and Jack H5 and 2060G have Shaft, but Jack 6691/2 is a machine that also uses a timing belt. Whether it is due to thermal expansion of the shaft during long time operation or maybe it is incorrect or insufficient space for a classic shaft, I do not know, but Durkopp Adler is an industry-standard and all possible factories that make car interiors and seats for luxury vehicles like Mercedes, BMW, Rolce Royce.. etc. use these machines daily. There is nothing better than that in the world, so I believe that this belt drive is the least of your worries. And here I just remembered to look at the new Delta machines that cost 10k + and they also have a belt.

-

Thanks for your effort really. First, there is no Pfaff anymore. It is Shang Gong now and all machines, except the most expensive ones, are either made in China or in Minerva factory in the Czech Republic, like Durkopp Adler! Also, 335 are outdated construction. And here, I can't buy a new Pfaff 335 anymore. I can buy made in china clones and used one I can't find or they are in very bad condition. Clones are around 2000 euros (~2400$) here and I could buy all manual Durkopp Adler 669 Eco for 3300 euros (~3600$) But for the leather jacket you need a lot of space and a big flat surface to not damage the leather.. so... that is the main reason I would like a flatbed first. I have plans to maybe enter into fine leather purses segment, to clone Hermes purses range but right now, it is hard to find skilled workers. But if I succeed, I will buy 669 for sure or something like this: https://konsew.com/industrial-sewing-machine/jack-industrial-machine/jack-s7-intelligent-control-computerized-post-bed-roller-feed-sewing-machine if Jack goes out with a cylindrical machine, like this post bed one!

-

Thanks for your comment! Yes, I got your point. I gave a fortune some 17 years ago when I bought my first Juki machines. Everyone cost a small fortune but worked like a charm. Nowadays, if you are sewing in a Western country or Europe, you are making some luxury stuff, or you can't survive. I will never compete with Zara, New Yorker, Stradivarius, simply because my garments are 10x better sewed, from better materials, every stitch is in its place, all my zippers are YKK or RiRi... All models are greatly fitted and mostly targeted to girls with great body shape. I'm not politically correct. Couldn't care less for "curves"! I don't have plus sizes, only standard, "model" sizes! I want customers who could afford to pay more! 90% of my evening dresses are between 120 and 230€ per model (130-250$)... 10% are hand made with lace and rhinestones etc... those are 600+€ and those prices are at the upper end in Eastern Europe! So, I could easily afford a new machine from an 800-1000 €/$ price range! I always have a few new machines on the floor, so when somebody has some problem, they simply exchange the machine for a new one and continue to work. Later I check the machine to see what is the problem. So far, Jacks are GREAT machines. A long time ago, nobody liked Samsung and LG.. nowadays, they are standard... But wait a few years... I have TCL tv in my house. It is really exceptional, not great. Tomorrow, TCL would be like Samsung today. Also, DJI drones and gimbals... A few years ago, who would tell that some Chinese company like DJI would rule the world with their drones and hand stabilisers/gimbals! If you ask me, Jack is the new DJI! They are here to stay. Jack overlock C4 and C5 was 5 years miles ahead of Juki. Now they have C6 which is even better in every way... Juki release a new overlock to match those from Jack a few weeks before. Guess what... As I have Jack C4 mostly, I recognize a lot of parts from C4 series in a new Jukis... so, it is not a secret that Jack actually makes those for Juki! Also tone of other machines... Also, every change at Jack is a kind of innovation. They are removing electromagnet in new lockstitch machines and use servo motor for moving Presser Foot up and down! Both Jukis and Adler are still manual, or if you pay a price of a new city car for non-Eco version, you could get pneumatic! Not to mention a belt transport! Jack doesn't only have a DC direct drive, they have the latest form of DC engine, with high tech inverter drive! So.. when some of my Jack machines finally dies, I would simply buy a new one, sell a broken one for half-price or simply keep it for parts I have plans to sell my leather jacket for 500+€/600$. (high price for my market) I have plans to make a dream jacket, with best leather, real fur collar, Riri zippers and an overall great fit. Will use software and CNC cutter to cut bespoke. You enter customers measurements, software correct pattern and cutter cut leather to a client measure... if I can't sell at the high price point, I would not go into that... so I need really ultimate sewing solution.

-

Hey Wizcrafts, thank you very much for your efforts. Yes, i can try DNU 1541, but only a new one. And in my county, a new 1541 is expensive than slightly used (no any trace of use) Juki 2810-7. Also, i don't want any belt drive machine in my workshop. Only direct drive machined are accepted. Simply, i want a new technology. And i like Chinese Jack brand very much, because they give you all the features and all the automation without pneumatics, for a very reasonable price! And both 1541 and 2810-7 use same needle system...

-

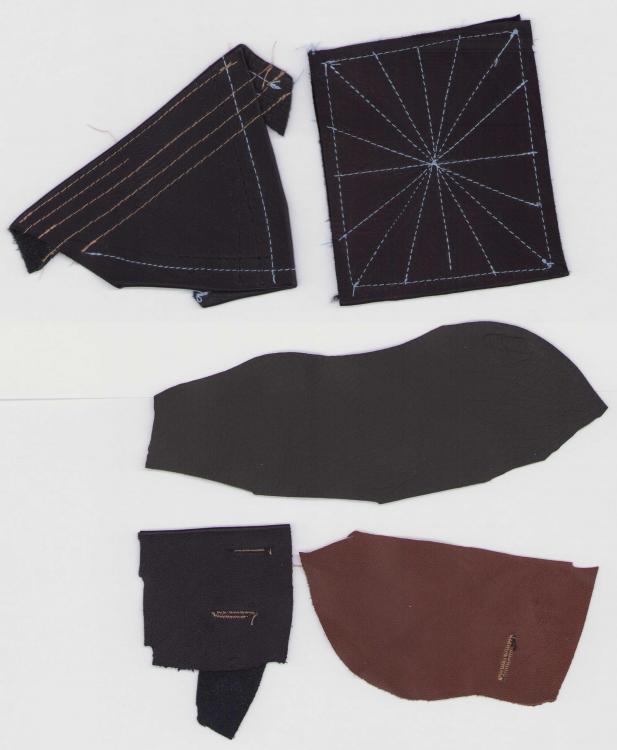

Samples of my test stitches, on my Juki 9000B and Jack A5e machines, with just ordinary needles and threads. Those are just simple tests, nothing else, to try leather stock I bought for a beginning. Also ordinary iron foot for textile. I have both top grain lamb nappa leather and Plongé lamb leather. First is leather with original grain and Plongé is corrected grain, for consistent finish across hides.

-

Guys, thank you very much for your answers and opinions. In my workshop, in my Lock Stich machines range, right now, i have: Juki DDL-9000B-SS https://www.industrialsewing.co.uk/industrial-sewing-machines/under-bed-trimmer/juki-ddl-9000b-ss-direct-drive-ubt- and Jack A5E https://www.industrialsewing.co.uk/industrial-sewing-machines/lock-stitch/jack-a5e-direct-drive-lockstitch-industrial-sewing-machine I could easily buy: H5 walking foot: https://www.industrialsewing.co.uk/industrial-sewing-machines/direct-drive/jack-h5-automatic-walking-foot-industrial-sewing-machine?search=H5 A6F needle feed: https://www.industrialsewing.co.uk/industrial-sewing-machines/direct-drive/jack-a6f-direct-drive-needle-feed-industrial-sewing-machine?search=A6F Jack 2060GHC Automatic Walking Foot Needle Feed https://www.industrialsewing.co.uk/industrial-sewing-machines/needle-feed/jack-2060ghc-automatic-walking-foot-needle-feed-large-arm Also, i have offer for very low used Juki 2810-7, exactly as in this video, but i'm in doubt is it overkill, to rough for fine leather jackets: Pfaff machines are only clones in my country. Also, cylindrical, i thought about flat bed first, especially for long seams, zippers etc, i need machine for stitching long pieces of leather. Needles, i can buy Groz-Beckert here. I would try with LR, SD, S, R points. Threads, i could buy this: https://industry.guetermann.com/en/products/product-finder/mara-80 https://industry.guetermann.com/en/products/product-finder/mara-70 https://industry.guetermann.com/en/products/product-finder/mara-50

-

Dear friends, I'm working with textile, making ladies evening dresses for more than 10 years. Also men's business shirts in the last few months. So I have some experience in sewing, cutting... I would like to start manufacturing expensive, high-end fashion jackets from fine and delicate leather, like a lamb (sheep) napa leather. I'm not interested at all in calfskin or any other hard leather, like those used in bike jackets because those can be bought very cheaply in my market! Could you please give me your opinion, what type of sewing machine I would need for that kind of soft and thin leather? Mostly 0.6-0.7mm is the thickness of the leather I will use. The attached photos are from the jacket I will clone for the beginning. That is a high fashion brand jacket which I like very much and would like to use that as a milestone for me, to have some quality standard, a target how my product should look! In the attached photos, you could easily see a black thread. Could you please tell me what kind is that thread and what is the thickness of the thread used in this jacket is? Leather is Lamb Nappa as I wrote in the beginning. Thank you very much for all the useful answers!