MariaMS

-

Content Count

48 -

Joined

-

Last visited

Posts posted by MariaMS

-

-

Sorted. It turned out to be the usual things - grease was a bit dirty, but the main issue was lint and broken needles in between the feed wheel and the hook, and also a heap of thread wrapped around the base of the hook assembly! So the same issue as most of the domestics I've worked on, but just looked more complicated.

-

A friend recently got given a bunch of machines, including a Pfaff 191-5. it looks like it has been sitting for a few years. The needle system and hook timing are now working fine, but then I noticed it was sewing in one spot..... it appears the drive shaft the runs the continuous wheel feed is not moving. If I hold the stitch selector button down, I can't move anything, and when I let it go it just disengages. I have doused the gear train in kerosene and PB blaster, and will let it sit for a few days. The worry is the condition of the shaft - to me it looks like an aftermarket part, and has blueing showing partway along..... would removing this shaft be the first step to track where it is jamming, or could there be something more obvious I am missing? I did open up the cover plate over the main vertical drive shaft to check, and the grease is not hard. Sorry I didn't take images of the top end, I can do that next time i am at the workshop.

-

9 minutes ago, Constabulary said:thanks for that- i had a quick look on their website, but contacting them is an option. You are totally right on the cost front. it may be another machine pops up in the future that I can gather parts from....... there seems to be all sorts hidden away in old sheds!! It will be interesting to see if it works as is - makes me wonder if the system was replaced with a standard presser bar. I am not that familiar with them as yet. Part of the issue with contacting Mayfar would be I haven't figured out the part numbers I'd need to ask about! I have the manual, but it is a bit tricky working out what the parts look like!!

-

Hello! A friend recently acquired a Singer 31-19 as a tag along to a bunch of other machines. I've freed it up, just the bobbin case to clean and then I can check the timing and see if it will sew. Sadly it looks like most of the kick foot assembly is missing- see pics. It currently has a standard high shank foot instead. Does anyone know if such parts are still available? We are in New Zealand.

-

-

14 hours ago, gordond said:those two pics are perfect, exactly what I need. I couldn't quite see it properly on your earlier image..... thanks heaps!!

-

On 4/3/2022 at 12:32 AM, gordond said:Actually... is your machine a 7-33?...

Just wondering if your 7-5 has a spring mechanism that returns the foot forward after is is pulled back by the action of the feed dogs..... the foot has a tiny hole in the back, and then there is the L shaped bit, as if there could be a compression spring on a pin nestled in there to do the job. Tried a coil spring and it worked great but restricts the movement backward. A ballpoint pen spring will be the net thing to try, but would like to see pics of what it SHOULD have in that spot...... and does the thread run through there, or should it come from the take up lever through the slot and skip the tab thing?

-

I got another step further today - I had trouble with getting the tapered pin that holds the foot in place back in, and just had a thought that maybe I had the presser bar 180 degrees out.... so pulled it around and it went back together perfectly. I had a friend helping today and we developed a better take up spring. He also questioned why the foot wasn't travelling the whole distance, and we decided maybe there should be a spring in there too, so the foot can flick forward properly......got all that sorted and wow, we suddenly have perfect stitches!! If anyone has a 7-5, I'd love to see a pic of what the two springs actually look like LOL

-

The Singer 7-5 has graduated from the intensive care ward onto her own bench. 2 oak headboards and what looks to be an old steel industrial sewing machine frame that was kicking about in the Engineering shop. Now I know it will look OK, I'll stick the frame into the electrolysis tank and give it a clean up. It is a good height for standing up at. This shows the machine with a single coat of rustoleum flat black. I'll probably do the frame in the same way, and leave the wood light coloured.

-

1 hour ago, catskin said:Plate looks VERY MUCH like the one on my Adler 20-2 see if you can find one of them to try. I was told that quite a few parts are interchangeable. IF that is true it might get you what you need. I don't have a spare or would offer it to you. I could measure if you post measurements and tell you if it is the same.

Gordond helped me out and sent this (see "Singer 7-33 under restoration for the whole thing - I couldn't change the title, but it shows my rescue of the 7-5). I'll look up the Adler plate. This machine takes a 7x1 needle, is that the same as your Adler?

-

10 hours ago, gordond said:Possibly Sewingtime Auckland.

It uses a 331 system needle. same needle as the BUSM #6 (Pearson 6)

ta. I'll get in touch with them.

-

-

On 4/14/2022 at 10:30 PM, gordond said:Correct

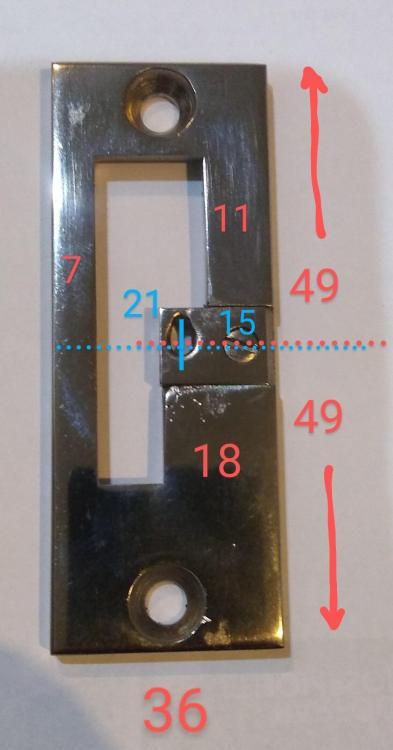

Hi I'm still trying to get dimensions for the 7-5 needle plate so I can make one - I asked in a new post but no responses so far...... any chance you would have time to do a measure up and add to a photo? We managed to make one OK but I think the needle hole was maybe a bit small (1.5mm) and was super close to the edge, which may mean I need to adjust the feed dogs more to the left to get a bit more of a margin so the hole can be a bit bigger.... I ended up breaking the needle as the tip caught the edge.

-

We managed to get a plate roughed out, but the needle hole looks closer to the inside edge than it should be, which could be to do with the feed dog adjustments. I noticed today there is a slight slop sideways, so I will have a go at adjusting them slightly further left, which would give more metal between the edge of the plate and the needle hole. 2 questions, what size is the needle hole usually, and does anyone have a plate they could measure up for me? it would make a repeat plate a bit quicker to make.....

-

On 4/20/2022 at 8:18 PM, gordond said:This is the long arm BUSM#2 housing the complete shuttle.

It will never be restored to concours condition as it too survived a fire at it's Owaka Wool shed home.. complete with sooty remnants still in it's nooks and crannies. No signs of frostbite or wind damage..lol! (I haven't been back to Owaka for 20 years ..Riverton was bad enough ..even colder than minus 15 deg C blast in Denver)

What a beauty!! Nice history too. DO you know of anyone selling needles for the BUSM #2 machines in New Zealand? I only have one - it would be great to start using it more often on the various bits of harness in the Livery, but I don't because of the lack of any spares.

-

2 hours ago, sandmanred said:If it can be dismantled it's possible it can be saved. Once it's all cleaned up you can better assess the condition. If there's wear or corrosion severe enough a there's a chance a person with a TIG welder could build up the worn area. Then recreate the grooves. Filing is a not out of the question. I'd look for the triangular shaped files used to sharpen handsaws. With some clever clamping you could probably guide the file to create uniform spacing in the teeth.

it isn't the dogs that are the issue, they cleaned up fine..... it is the plate that covers them that I'm wanting to make a new one. The other was so rusted I thought it couldn't be saved, so cut it off to gain access to the hook assembly. Rewelding it could be a possibility if I still have the other bits perhaps, currently I only have the ends with the screw holes.

-

7 minutes ago, gordond said:excellent - great to see the inner spring. I tried ours out today, but the spring has sharp edges rather than rounded - I found it is an issue when the bobbin is fully wound, as the pressure is so high it causes the thread to jam and pull into itself. I unwound it a layer and it was heaps better, managed to get quite a stretch of a reasonably tensions row of stitches...... as usual forgot to get pics.... will get net time I am up there.

-

The Singer 7-5 I'm working on had a feed dog plate I thought was past rescuing, so I made up a set from wood. I'm going to have a try to making one from 3mm MS today but I'm not sure my skills are up to the task..... does anyone happen to have, or the skills to draw up a laser cutting file for these? I do have my Verniers to do a measure up if my "drill holes and wear out a few files" approach is a complete failure..... at least this time around I know to get the plate fitting at the screw holes first up, and THEN mark the needle hole!! Then again, maybe I need to beg some lessons on how to use the milling machine.....hmmm that could be a fun learning curve!!

-

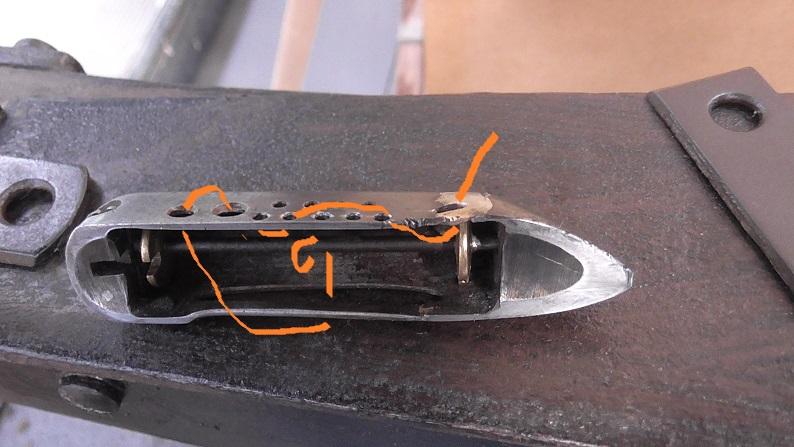

6 hours ago, gordond said:Shuttles are different... BUSM#2 smaller and no inner tensioning spring

Any chance of a pic of the inside of your BUSM#2 shuttle without the bobbin? I'm wondering if the one I have was retrofitted......Also interesting you threaded the tension holes direct from the bobbin.... the domestic transverse shuttles I've seen go around the bar on the opposite side first as it allows the thread to pull off more evenly..... I admit I haven't used our HM much so haven't tried it threaded that way yet - but interested to know your thoughts as per the pic with orange "threading"

8 hours ago, CowboyBob said:I wish I knew more about there but here's a pic of one we have ser#9446 & it has a spring for tension on the shuttle.

Thanks!! yeah it would be cool to have a database of serial numbers and photos.... but I guess that would be a huge job... any chance of a pic inside the shuttle without the bobbin?

-

7 minutes ago, gordond said:Looks legit... Had a search .. couldn't find the date info .. there are a few here that have more info than I do ... see if someone can contribute

I got as far as this https://en.wikipedia.org/wiki/British_United_Shoe_Machinery

so somewhere between 1900 and 1910 possibly. Unless it is a date - 6/2/18

-

-

1 minute ago, gordond said:.think someone did pinpoint the dates via the serial number ...

Where are the serial numbers? I did track the brass plaque of the supplier H Oscar Hewwit to around 1910 via Papers past..... there is also a bit on the BUSM on Wikipedia, so I can add that in too for now. Ta for your help!!!

-

3 minutes ago, gordond said:Early British United model when they started producing the Pearson ..

great, thanks! Any idea of dates for either of the two models? At the moment I simply have "pre 11900"

-

The other machine we have is somewhat the worse for wear, having possibly been involved in a fire at some point in it's life...... thoughts on the model, again possibly a Pearson of some type? I have a feeling I saw a container which could well hold some of the missing pieces, but I hold little hope of getting it back to a working machine. I will uplift it from the Livery onto my operating table once the Singer 7-5 has a place to sit, and have a closer look.

Using a Singer 45K25 for Darning

in Leather Sewing Machines

Posted · Report reply

Interesting topic..... I have what I think is a Singer model 47 coming. Don't know the subclass as it went straight to storage and I can't see it in the pics. It currently has a roller foot, but I want to look into if I could get it darning. Was wondering if anyone has modified a domestic darning foot...... there are a few different ones that might work perhaps......