Spicytacoman

Members-

Posts

42 -

Joined

-

Last visited

Profile Information

-

Location

Davenport FL

LW Info

-

Leatherwork Specialty

Wallets, bags, journal covers

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Spicytacoman's Achievements

Member (2/4)

-

I wish I had known that!! Thanks for that! I know he has the needle chart thanks to you all but, I didn't see he actually sold them, I seen he sold thread though.

-

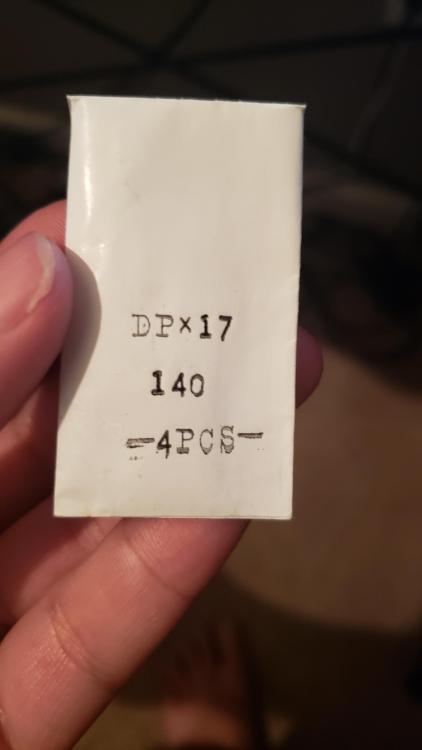

Im so confused. I bought these organic needles 2 times on Amazon already and it stated dx16 but have gotten 2 sets of these? https://www.amazon.com/sewing-needles-walking-machines-135X16TRI/dp/B0779K9KQ9?source=ps-sl-shoppingads-lpcontext&ref_=fplfs&psc=1&smid=A3HPQS1YHCBIBL Is there a better site to buy leather needles from? Dpx16,135x16 different sizes? Im so confused man and frustrated that I think I got the wrong order 2 times already.

-

I loosened the bolts on the left of the safety clutch so I can turn the rod without touching the rest of mechanics behind the clutch. Thanks for pointing out you are more experienced! Im sure we all can understand im new anf have much to learn lol.. I've had shoepatching handcranks before as well as a nice video on YouTube to help with what I thought might be the issue since this was the case on previous machines I've had that didn't pull up the bobbin thread qnd got lucky with my guess seeing the hook was off time.

-

I wish I seen this while I was killing my brain... lol almost identical situation... lol wow thanks ill keep reading to see if he fixed the bottom thread issue too!

-

I figured it out with some tinkering and head scratching... Like you guys said the needle was not meant for leather and was dull causing it to struggle piercing the leather along with some other issues throwing the timing off. Fixed the hook timing and realized the reason the belt was spinning because I was using too low speed on the servo and when it lost momentum couldn't move the pulley unless i backed it up and gave it more power. Replaced the original needle with another dpx17 until my dpx16's comes tomorrow. Also raised the servo speed up one notch and no more issues. Fixed the looping on the bottom by tightening the top thread tension. Now, the only thing im trying to figure out is the bottom stitches are a little slanted whereas the top stitches are straight. But im figuring it out.

-

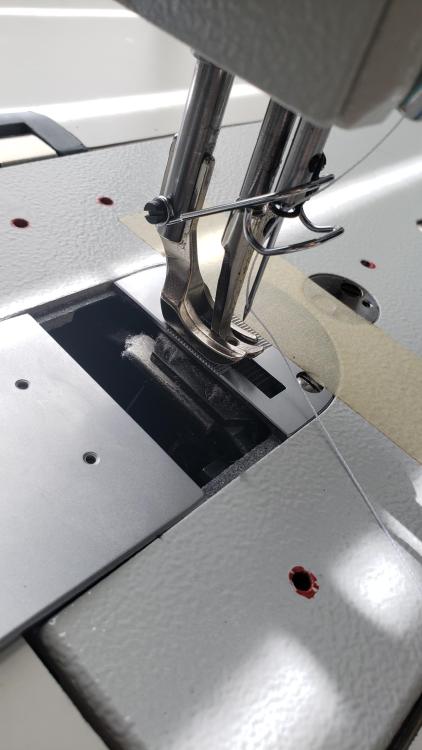

Long groove is on the the left perpendicular to the outer machine side. That is correct, needle is fully inserted and fully tightened. Thread is pathing from the left of the whole to the right. There was an issue where the lifter foot screw was loose and was clipping with the walking foot. I adjusted that so they no longer touch and are straight. The seller showed me how to thread it and I've kept it the same. That was pretty much it. The only time I spin it clockwise is if I felt it locking to back it out / release the thread to pull out. I have no idea what a drop test for yhe bobbin means.. im using the original ones that come with the 206rb5. I made sure the thread unwinds counterclockwise and followed the path in the case to get to the little eyelet. As for holding the thread before sewing, I have! I will handcrank the first 2 stitches while holding them back before using the motor. Inserting the bobbin i do get the click! Yup I certainly did. After fixing the lifter foot issue it is a bit easier. When the presser foot is up it handcranks with no tension at all. As soon as I put the presser foot down, and the walking foot meets the feed dogs, i believe when the lifter foot needs to start moving up is when it gets tight and has resistance to turn the crank. Not sure if that is normall? It isn't allowing me to add multiple pictures..

-

Everything you guys say helps! Im starting to stress out man... I've had this thing for one day, started sewng well at the sellers place. Brought it home, and as you know, the belt started slipping.. I adjusted the angle of the motor to put more pressure on the pulley that worked however, stepping back and looking at the the situation now I think the situation was something else. Started sewing this morning and started getting the thread caught in the bobbin casing more and more often. Pulled the bobbin out and removed the thread that was caught after each catch. Popped the bobbin case back in and now the top thread will not pick up the bobbin thread. Handcranking the pulley has tension now without any material under the foot as soon as the needle starts reaches this position on the down stroke and feels like it is getting caught but the needle isn't even through the hole yet... my joy is slipping fast haha. Been trying to figure this out for about 3 hours and reading for an answer online..

-

Really? So not like a gas pedal position? Figured it would be easier to adjust pressure this way. So you mean to have it as flat as possible?

-

It handcrank sews fine. To be honest, I believe it has to do with the needle. When there is no material under the needle, it runs just fine. I guess it is the needle. Handcranking it with the material is doable however I do feel resistance. I guess since the original thread was thinner and the sellers house it was easier to run when I first tried it before transporting?

-

Where can I find information on needle sizes and what they are used for? I know wiz has had to have made a guide somewhere! I couldn't find anything on Google. What brand for industrial needles do you all recommend for these new needles? I had no idea.. I tried looking up 140 / 22 dp x16 and can't find some. Im seeing 135?

-

I think that is the main thread size I will use, im currently working for the last 2 hours of my shift but this is what I found in the packaging. Not sure if this is what is currently on the machine at the moment however. That needle should work well for leqther and #138 right?

-

-

Lol right!? Now my thread is slightly thicket than the one he used but barely. Im using #138 not sure the one he had but it is a tiny bit thinner. But the amount I had to lower those nuts to keep that belt from slipping was like 3/4 of an in which I thought was excessive but what do I know.. lol

-

So the thing is I dropped it downward more to put more pressure and that seemed to help the situation. Have thread tension issues im working through now with looping under the bottom so im slowly tightening it until the looping stops. I think im almost set to start sewing!

-

The belt slips inside of the pulley, as in it isn't turning the pulley but the belt spins. As far as tightening the belt,I dont see any tensioners for it to tighten.