TES

Members-

Posts

12 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by TES

-

I have a Techsew 5100 SE for sale in Richmond TX. Sorry, but I cannot ship this beast. It has the nice servo motor, aux light, laser light, removable flatbead and plenty of thread, needles and bobbins. I purchased this about 1.5 years ago and never have used it other than to get it sewing. This machine likes to sew thicker materials. I have the instructions, needles and thread to "tune it down" to be able to sew thinner material. I sew everything by hand. I have attempted to use it a couple of times but cannot sew a straight line for money. I just don't need it to build the things I like to make. I have a bunch of pictures, but cannot figure out how to attach an image from a url. I can email them if anyone is interested. $2700. Thanks, Tom

-

Many thanks for this information....EXACTLY what I needed. Thanks again for all of your comments. Tom

-

That is two layers....but they are probably two -three oz layers.

-

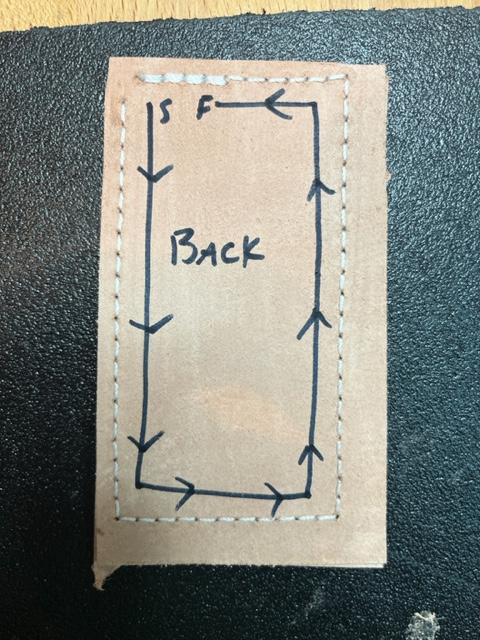

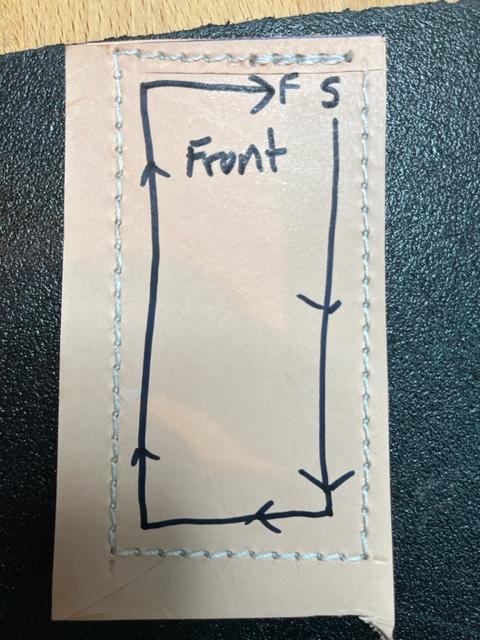

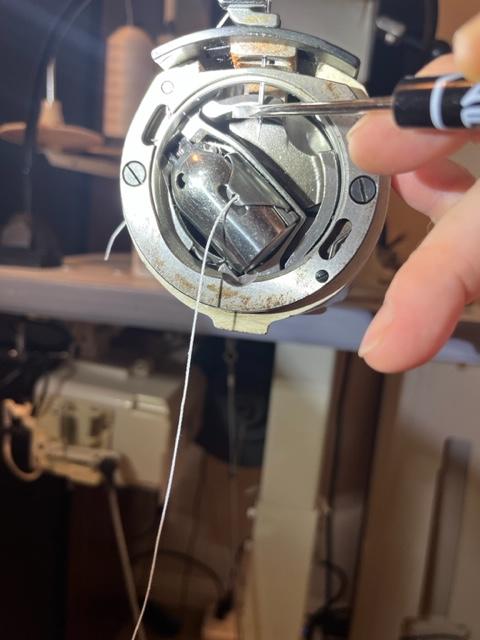

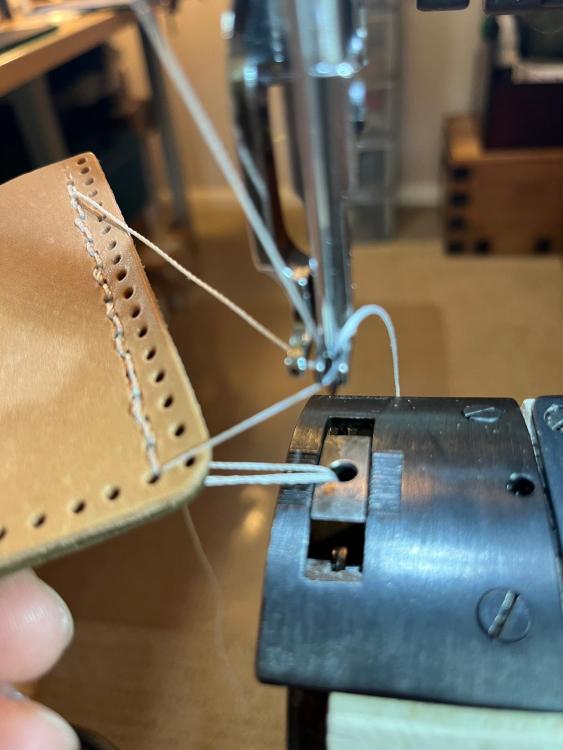

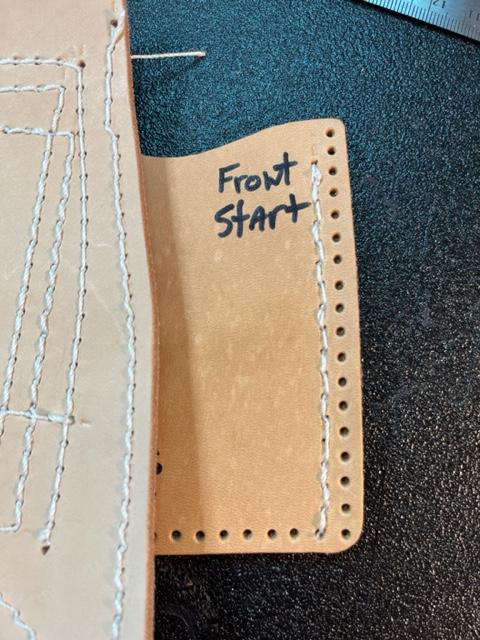

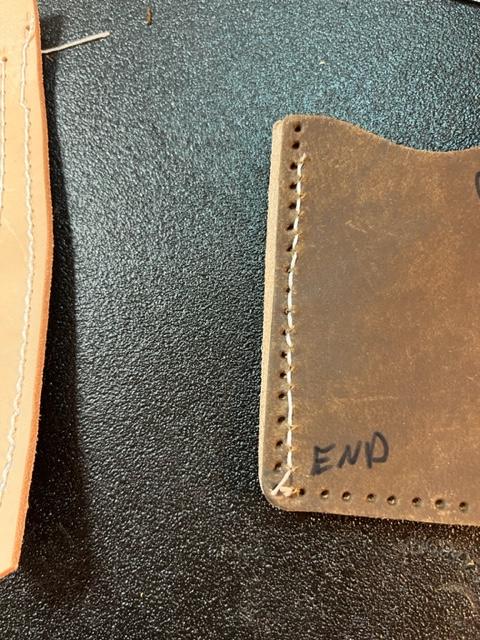

Partial victory! I went out this morning and took the bobbin shuttle out and cleaned everything. I polished all of the surfaces with 2000 grit and finished off with 2500 grit sandpaper. I could definitely feel the corrosion when rotating the bobbin shuttle....No more though....it is now polished up and smooth as silk. I made the first stitch and it did the same thing (top thread looping around), but it was a much, much looser loop. I loosened the two top tensioners and changed the EPS to stop in the needle UP position. It has worked flawlessly ever since...Flawlessly in that the top thread doesn't catch or loop in the bobbin shuttle.....I still can't figure out completely why the little knots are showing. I have the bobbin thread as tight as it can go and the top thread is now no as tight as it was. I think that the tightness was caused by this: on the tensioner where you make 1.5 turns the last half turn of thread was laying on TOP of the bottom thread. I rethreaded and passed the half turn INSIDE the first turn....now the thread tension seems to be much smoother. All of the tension issue I think was from the bottom roller (1.5 turns).... When you lift the feet does the tension drop to, or close to zero at the disks? Yes sir, when I lift the foot, most all of the tension on the top thread is gone. I thought that tightening the bobbin tension would pull the knots down toward the back of the work.... I am going to order new needles and thread today. I did change the needle yesterday to a 23....but I only have the Tex207 for thread (machine thread). The back stitches look perfect....front stitches have the knot showing...please see below. My preference is that I like to see the stitches, meaning I like a heavier thread when possible....The thread I am using now says Techsew Tex207. Based upon the chart, I should be running a size 23 needle. What brand of thread and needle do you recommend? I'm brand new at this... I thank you all again for your help. Tom

-

Thank you all for your comments. Yes, I didn't loop the top thread through the top guide twice...I was trying to lessen the tension. I have corrected that now. I have been at this machine all day attempting tension adjustments, videoing and attempting to sew. I am touching the piece inside the bobbin shuttle that the top thread is looping around on the second stitch every time I sew. It looks like some sort of cam or similar. I also have knots showing through the needle holes. I went through the tightening process for the bobbin and got to the point where there was no more takeup in the screw...meaning I could not increase the tension on the bobbin any more and I still had the same knots showing. I spent two hours loosening/tightening the tension on top and bottom and nothing really corrected my issue with the top thread getting caught on the second stitch...I did get a little improvement on the knots showing throught the needle holes. I changed needles twice to see if that was the issue, and it did not help. Thanks Al. I'll check that position next time I go out to the machine. Thanks again for all of your help.

-

I thought that I had erred by overtightening the two screws holding the bobbin shuttle. I bumped them snug and backed off 1/2 turn, and no real luck. The top thread has a lot of tension...fyi. I uploaded some videos to youtube so you can see what is happening.

-

BINGO! I tightened those screws tight. I'm headed out there in a bit, watch the two videos above and adjust the shuttle retention screws, check it and see how it sews...might need to adjust thread tension....I will follow up. I can't tell you how much I appreciate your help. Very thankful. Tom

-

Good morning sir....Thank you again for your help. Yes, I am holding the starting threads back for the first few stitches. Yes, the thread is going through the inside foot and exiting out of the back. I have measured the travel on the check spring, nor even looked at it when starting to sew.....I have videos but they are too large to post here. Could this all be due to thread tension being incorrect? The top thread is very tight and the bobbin thread is MUCH more loose. I was thinking about the situation last night. This all started after I got the machine home and threaded up to start sewing. The only initial issue was that the top thread was twisted and some of the knots were slightly showing on the top side. I did get a thread tangle in the bobbin area ; so much so that I had to remove the plate holding the bobbin shuttle in place to remove it......This is when my problems began. I videos online was a Techsew 5100, but clearly a different vintage and did not look exactly like my machine. It took a couple of days and Techsew did send me the video for my exact machine. I found that I had spooled the top thread incorrectly when watching that video. I rethreaded it correctly, but I am thinking that I may have screwed up the tension when removing the plate holding the bobbin in place.... Based upon the video, the needle/bobbin timing is correct. Question: Could this be a thread tension issue? The top thread takes considerably more pressure to pull thread than does the bobbin thread. When I removed the bobbin shuttle plate, did that release the tension for the bobbin thread? I don't know enough about these machines to diagnose. I do know that the loop being formed in the bobbin area is happening on the second stitch and if I let go of the top thread and pull the bobbin thread very tight it does not happen. I am going out there this morning and put some more tension on the bobbin thread and see if the problem gets better or goes away. Thank you again for your responses. You have been extremely helpful....much more so that the manufacturer. Tom

-

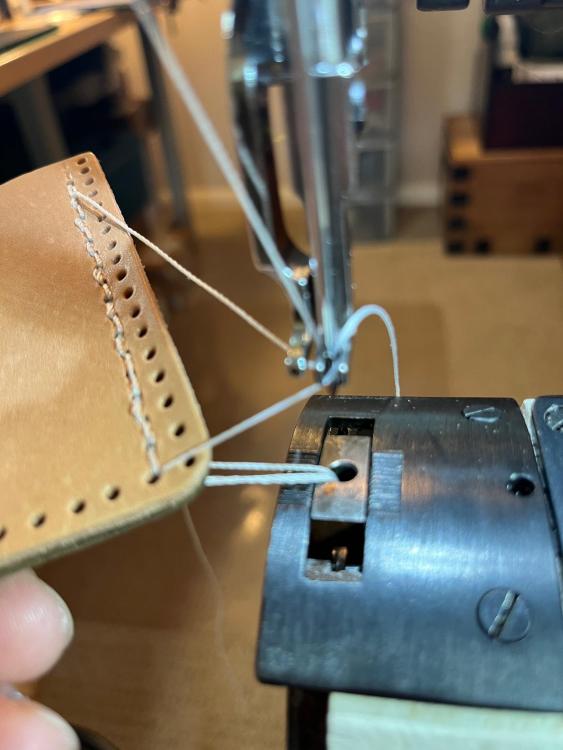

Thanks for all of your replies. Here is what I have done/found: Thanks KGG for the thread. Mine appears to be threaded as per the video reference. I confirmed the bobbin hook timing with the needle. The problem exists exactly at the second stick everytime. It appears that the bobbin thread is being either pushed into the bobbin by the needle or something is causing the bobbin thread to loop back into the bobbin. The attached picture is what happens each and every time I sew....it always starts on the second stitch. Back stitches look fine. You can see the loop pulling through the needle holes on the top side of the stitch.

-

The system will not let me upload the photos of the threading...says I can only upload 1.46mb and the files are actuall 900kb...I assume it is a daily limit. The thread guide on the top tension disk is at the bottom of the disk. The thread coming from the top thread post actually is so low that it hits the lifting mechanism of the foot. The thread enters the thread post in the top hole and exits towards the top tension plate through the bottom hole. The first few stitches with this machine did give me twisted threads on the top stitch. I found that I had it threaded incorrectly, corrected it and the twisting disappeared, but this other mess appeared at that time. Thanks again, Tom

-

Thank you for your replies. I don't know exactly what needle is in the machine....I can only make out two numbers as the packaging has faded....I also have two additional packs of needles that came with the purchase...both are mfg'd by Organ Needles...One is 160/23 and the other is 140/22. I can get the needles you suggest in a day or two. The first picture below represents what I see when finishing a stitch line. Thread is wrapped through the presser foot and there will be three or four pieces of thread coming up from the bobbin with only one of them actually leading to the bobbin. Pictures two and three are the top and back of the stitch. I did check the needle timing with the hook and changed to a new needle. It appears to be timed properly according to the video and after changing the needle, the stitches appeared to get uglier....long groove is facing left. Thank you again for any input. Tom

-

Thanks for any assistance you might offer in advance. I am very new to leatherworking. Two weeks in actually. Last week I purchased a used Techsew 5100. I watched about 15 videos of various topics from threading to adjusting. I loaded up a few bobbins, threaded the machine and off I went to practice with the machine. All started out well and then I started to get a couple of issues. Here are the problems: Initially, the top stitch looked somewhat twisted and the knot was almost popping up through the needle hole. The thread is Techsew Tex207 and the needle is Grosz-Beckert ?25....I can't make out the exact numbers as the label has faded. I also had two or three occasions where there were multiple threads coming from the bobbin when I would finish a stitch line. I took the bobbin out and had to remove the mechanism that holds the bobbin to clear it. This may have been a mistake. I put the bobbin mechanism back in, checked the timing based upon the video and all seemed lined up correctly. Now, the top thread seems to get caught up in the presser foot and the same thing is happening with the bottom thread. The bottom thread will have multiple threads coming from the machine. I did place a call to Techsew for support. I was informed that the warrantly did not apply to me and that any questions should be directed to info@techsew.com. I did send an email to Techsew asking for a copy of the manual for the machine which they did send about 1.5 days later. I am waiting on the manual for the motor now. I didn't mention this problem to the tech support person because I really don't even know the correct terminology just yet. I had to Google what the inner foot was called just to write this email. I hope that this is something you might be able to comment on to get me in the right direction. Many Thanks, Tom

.thumb.jpg.dff34d22627dca507e49919ea4e92adf.jpg)