Ana1234

Members-

Posts

28 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Ana1234

-

Hello, I'm sewing a bag using very thick faux leather and the layers are building up... Any ideas on how to make the bag less bulky on the outside? How can I press it without using a hot iron? Which tools do you use to get flat seams, to get rid of the bulky look? Thanks!

-

I changed the belt when I put the servo on and it was not engaging properly with the new belt. I just had to change the position of the bobbin plastic part that is screwed into the table. Learning every day

-

Hi, it was working fine until I got this servo installed. Always follow the instructions you gave now. Never had a problem with it. Could this have happened perhaps when they installed that needle positioner, perhaps something was put out of place. I'll send this to the repair guy, thanks.

-

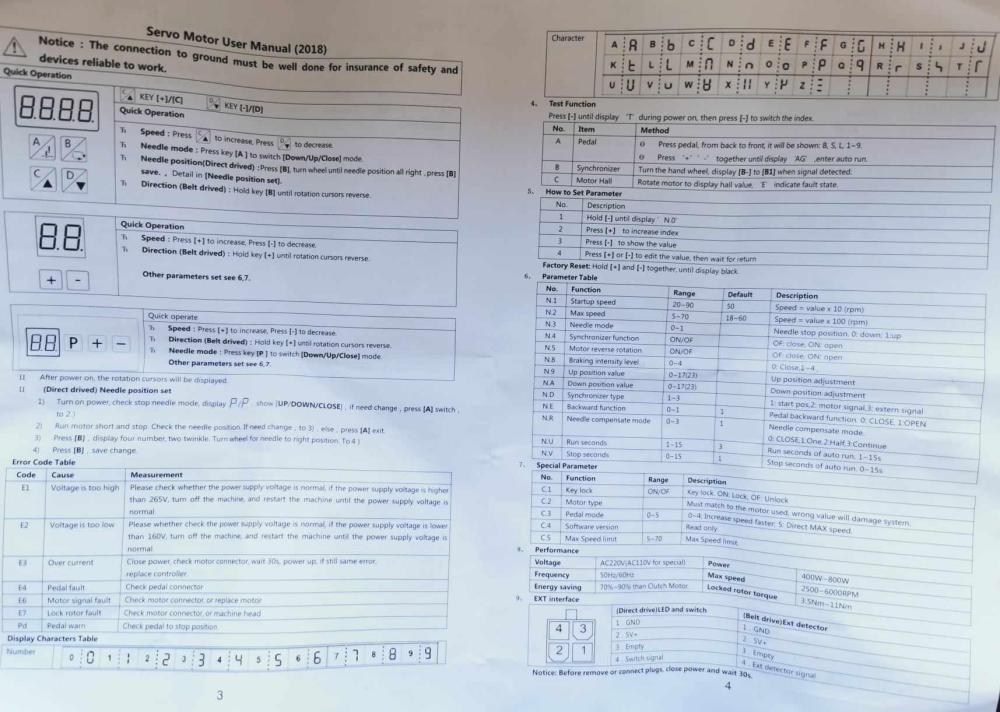

Hi, just installed a servo on my machine and now the bobbin is winding painfully slow? I was told I need to set the speed when I wind it (it was on maximum sewing speed when I did it). Can anyone see where on this manual I can read about setting speed for winding the bobbin? This page is it, I didn't get any other manual with it. Thanks

-

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

Thanks! -

Cheers! I'll give this a go!

-

Hello! I placed the same thread in my industrial machine as I was using on my domestic machine and the stitches came out a lot darker, by quite a lot! Any suggestions on how to clean an industrial machine, where and what to use so the colour of the thread don't get tinted? Could this be because of oil? Or just dirt, perhaps between the tension discs?!

-

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

. -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

Hello, installed the servo now and must say I'm happy I went with the needle positioner!! After having had a nightmare with the clutch motor I am super pleased I'm finally able to get my needle exactly in the place I want it. I paid 200 eur for the installation and the motor (Chinese no brand). I'm happy I didn't go for the installation myself, it would have taken me ages to get it right. Must say its not sewing as slow as I thought it would but it's much better and it works for what I do. No need for reducing the speed further. Winding the bobbin takes ages now though, it's super slow although I set it to max speed. Any ideas why this is happening? I attached a video here and a photo. Thanks for all the support!! Appreciate it. sewing speed.mp4 -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

OK! I'll go with this option then. You guys mentiond in the beginning that I should do both at once but I guess problem solving runs it's course and it takes time to get to the right decision. It's good though as I have learnt a lot! -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

Then the Vevor is to fast? It starts on 500rpm?! -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

I do but I'll get some help anyways. Mechanical skills I have non! But in the times we live in you can learn anything if you have wifi -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

What is this no name about? I went to the local sewing shop to take a photo of a servo motor. Owner whom is not at the shop currently said I should wait for him to get back as he has a servo motor in stock for me. I went there to check the brand to do some research but they could not give me a number, name or anything??! They took out a box but didn't open it for me or tell me any specs of the motor (other than that it is a 750w motor). Found that shadey... -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

Ok thanks!! Did you buy a speed reducer by any chance that you installed with the servo? -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

Found this - https://m-eur.vevor.com/ac-servo-motor-c_11222/sewing-machine-motor-220v-750w-brushless-energy-saving-servo-motor-industrial-p_010611078687 Seams ok! The 550w is only 20 eur cheaper. Thanks for the tip. Free delivery! That's unusual... I'm just starting out so I'm on a budget as well. -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

The 500w is 100 eur -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

Thanks for tip on the servo. I will check that brand out! OK good to know I can increase the speed a bit although having fitted the reducer. It's really not a lot I'm talking about but I would need to work up the speed from time to time. A German distrubitor has these servos - KF 800 W (kraft sewing) €170 Hightex HVP € 235 I prefer buying from a dealer rather than Ali express, Ebay or Amazon in case I need some support or if something goes bad. Perhaps any of these are good?! -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

Ok super grateful for all advice I feel confident now to pick the needed gear. This was a crash course into speed reduction!! I will report back how all of this turned out. Probably in August after holiday season. All the best! Just one more thing, with everything fitted and I've achieved that slow stitch how fast will I actually be able to go after that? I don't need top speeds but sometimes I get upholstery work and I am sewing curtains for TV commercials so I'd like to take it up a notch for those projects (now and then). Will the extremely slow speed set up be a stress on the machine somehow if I turn the speed up a bit? -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

Ok thanks for all info, appreciated! I will discuss all options with the technician guy (currently on holiday). Perhaps he has parts in his shop! I'll run all of this by him. Info on servos is super helpful. So if I got it right - - i either get a speed reducer (already built) and then I only need to attach a smaller pulley (45mm) on the shaft (or what ever it's called) of the servo. - or I build the system from scratch (cheaper option for parts but I guess I need to pay the technician a handy fee instead) with a larger pulley on handwheel and also the smaller 45mm on servo. A lot depends on the price of installation. If I go ahead to do it myself I'll be ready to sew in a couple of months -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

This looks interesting and it would be a lot cheaper - -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

Yes I did google it!!!! I'll spend some time reading and will probably be back here in a few days -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

Thanks all. Will any reducer go with my machine or does it have to be a specific one? I will shop around for another servo and also speed reducer, any support on the reducer is welcome! -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

kgg, yes that's correct needle wise. I did invest in some leather needles (DP16) but was told that they will tear the microfabric that I am using in between the faux leather. I ordered some ballpoint needles after that and they stitch nicely. But I will give the leather needles a go now to see what they do to the lining... I asked for the brand and manual when I bought it of course, she don't have it. I think she also bought it second hand and wasn't able to dive into the technical aspects of it all but I am determined to make it work. And I believe I need to fully know how the machine works in order to be able to adjust things myself in the long run. Otherwise it gets expensive. Did a search on the needle synchronizing. Maybe this is a stupid question but wouldn't I be able to just go with the first option 'really slow sewing speeds with stitch by stitch ability and extra torque for punching power by using a speed reducer'. And then just using the handwheel to place the needle down at a corner for pivoting? If I have a lot of control then surely, with time, I will know how to work the pedal in order to stop the needle where I want it? If it will sew very slowly? or I just use the handwheel? Isn't it more important to have the slow speed and stitch by stitch and the power, then having needle synchronizing? So from this conversation I might just need a speed reducer?? Saying that though the noise is a factor too..... it would be really nice to get rid of the noise. Then a servo would be better I guess. Appreciate the support! -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

It was from a distributor in Italy but I think so yes, I should be able to get something cheaper. I'm based in Slovenia. -

Swapping clutch motor to servo motor, please assist

Ana1234 replied to Ana1234's topic in Leather Sewing Machines

Chrisash thanks for the post, appreciate it! Lovely part of the world you are based, I was living in London for many years and yes, you can pretty much find anything you need in the UK. Also photography wise! Now though as you know, taxes and shipping costs are a problem... Can you recommend a speed reducer? Please see the motor I was offered below.. ----- Kgg, ok I'll go for a 750 watt. And thanks for the suggestion on model of machine, been pulling my hair out not having a manual and being new to industrials. Must say I had a steep learning curve, screwing apart this machine and learning about mechanics Something I was never interested in before... I guess I am not a fan of this stuff but I DO WISH to achieve that perfect stitch so learning is a must. Grateful for forums like this and the support given. I am using a 19 needle with the M20 thread (not sure what this relates to in TEX)? I have a slightly smaller needle for the M40 thread. I am sewing faux leather accessories and bags and there are many layers at times. My machine has been getting through it all well but I am struggling with the speed, that's all. It has a walking foot yes. Please see the motor I was offered below.. ---- dikman, yes it is daunting! Not my cup of tea. Thanks for the information. Can you recommend a speed reducer? Please see the motor I was offered below.. --- I was sent this option by an Italian distributor. Does anyone know anything about thos servo? Is it a good option for me? Comments from the company below, Chinese to me!! They say it is 350 EUR. For the motor I get is this price OK? - https://www.cowboysew.com/extra-heavy-duty-sewing-machine-servo-motor.htm It is brushless, 8Nm torque, with needle positioning for easy use, silence and low power. You need to add the synchronizer to the wheel so the motor can work with 2 needle position, up and down. ------ I can see that this brand has been discussed by some of you already.... Have you heard anything new about it?