Hidden

Members-

Posts

18 -

Joined

-

Last visited

Profile Information

-

Location

Netherlands

LW Info

-

Leatherwork Specialty

None (yet!)

-

Interested in learning about

Making gloves

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Hidden's Achievements

Member (2/4)

-

I can get a Ho Hsing G60 for €327 from a (very) reputable dealer in The Netherlands, but it's so expensive (and that's without the needle positioner!). Still kind of tempted to buy it because it seems to be the best motor, just to not go through this whole motor ordeal again lol. That one also seems to actually start at 100 rpm, as opposed to my current 400 rpm start and the Jack's 200 rpm. Decisions... this hobby can get expensive quick :')

-

Hi Daniel, the motor makes the noise even with the new belt (both the 3L belt and the SPZ belt). I replaced the bearings now, too, still makes the noise. I ordered a new 45mm pulley too (will need that anyway when I eventually make a speed reducer). Maybe I should try a urethane belt. But I think the whole thing being out of round as suggested above is also a possibility. The investigation continues. I’m probably just going to buy a new motor, though, and keep this one around as a spare. Considering the Jack 563A from https://www.sewtex.de/Motore--Gestell--Tischplatte--Zubehoer-fuer-Naehmaschinen--Stuehle--Leuchten--Transportwagen--Industriestuhl--Schere/Naehmaschinenmotor--AC-Motor-230-Volt--Industrial-Sewing-Machine-AC-Motor/Servomotor--AC-Servo-Motor-750-Watt--Jack-AC-Motor-JK-563A.html?XTCsid=df442c4e1fdb8a46685e9b04ef093c90 but from a search here on the forums I gather SewTex’s reputation is not so good. Happy to hear any other suggestions (within the EU and under €200, preferably).

-

That's what I'll do. Just ordered some bearings and accepted Pedro's third offer :') thanks for the advice, @AlZilla and everyone else.

-

Been in contact with the store I bought the motor from (vevor.de), and look at this: I replied I wanted a new motor or a full refund twice, looks like Pedro REALLY doesn't want me to return this thing (if Pedro is not a bot!). I found it quite amusing.

-

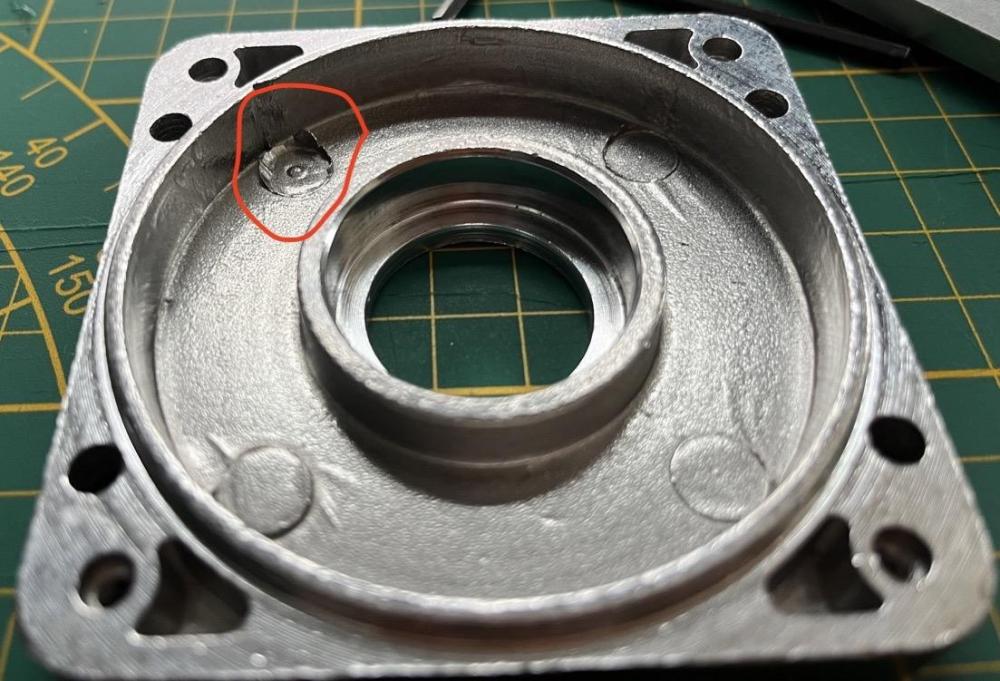

Apologies, what is the bearing face? Is that one of my circled parts?

-

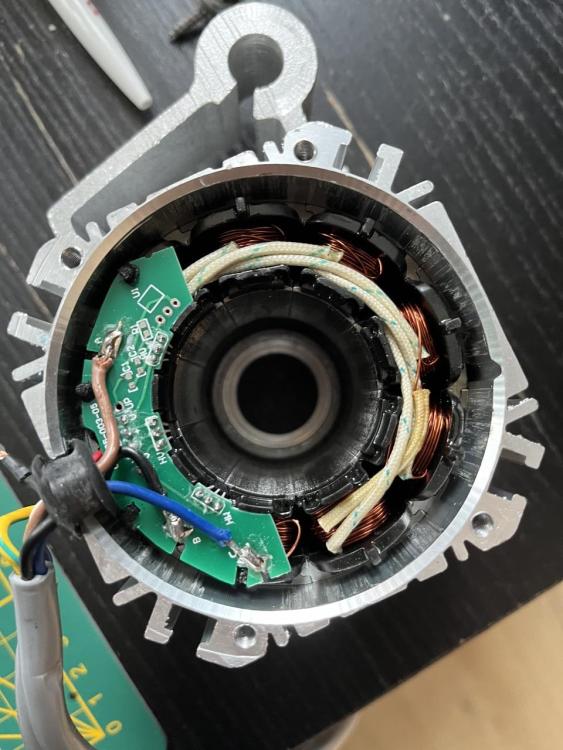

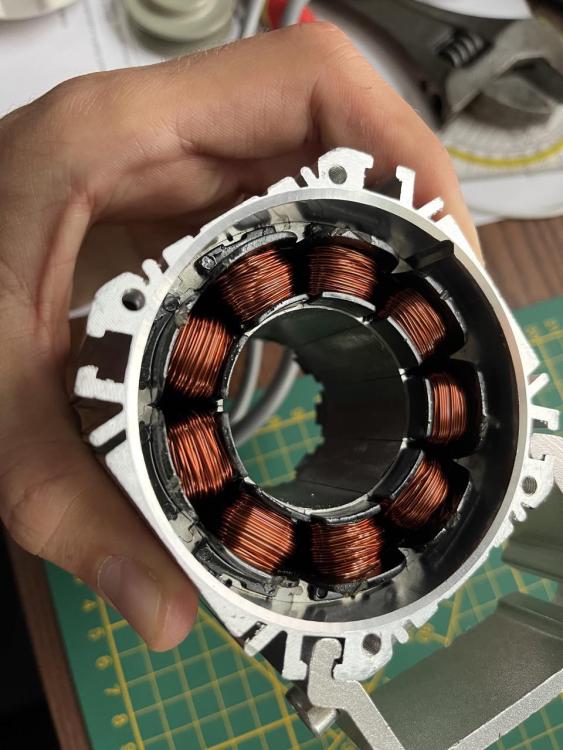

I took apart the servo again this morning for cleaning, here's some pictures: The rough patch on the axle is suspicious, but I don't know what causes it, as it isn't actually in contact with anything when the motor is assembled. It might not be a problem at all. The middle part is magnetic, which makes it a real pain to get any small metal bits off of it. I also found that rough spot on whatever you call the thing on the right ^, cleaned that up but then realized that it doesn't actually spin :') goes to show the machining on these things isn't particularly top notch, though. I also checked the bearings and they are lubricated, spin okay and don't make any noise. Here's a picture of the 50mm pulley, it does sorta-kinda look off-center a little bit (especially the first pic) However, more importantly, I just learned that these pulleys are supposed to use a 3L belt. The machine I bought came with an SPZ belt, which is the same width but taller. I bought an SPZ belt of the same size to replace it. The plastic part that can be screwed over the pulley also had some shavings of the old belt in it, which I found a little suspicious. Guess I'll order a 3L belt to see if that works better, maybe a new 45 or 50mm pulley as well. Or a polyurethane belt. Thanks all for your help so far! - Hidde

-

The noise I mean is the noise you hear in the video with the belt attached. Not the whirring noise without the belt. That doesn’t bother me too much. Is the whirring also a red flag? I’m not sure what these things are supposed to sound like! Dead quiet?

-

Just took apart the servo, cleaned whatever I could and put it back together again. Same noise One thing to note is that the sound you hear is in sync with the machine (one CHWUNK per stitch). I'm not sure if that matters.

-

Thanks for that suggestion! I did run it without a pulley, sounds roughly the same (it sounds quieter in this video because I filmed it from farther away). I replaced the old clutch motor on the Pfaff with the servo, unfortunately the clutch motor's pulley doesn't fit on the shaft of the servo, or I would've tried that one. That one feels very solid. The pulleys that came with the servo motor feel very cheap. It makes the noise with both of them (75mm and 50mm). I may try ordering a new, better pulley!

-

Hi folks, I installed a generic 750W servo motor (https://www.vevor.de/servomotor-c_11222/naehmaschine-servomotor-naehmotor-justierbar-befestigung-kupplungsmotor-750w-p_010611078687) on my Pfaff 545 H3 6/01 CLPMN a while ago, but it makes an irritating noise (I only found out it was the motor after presuming it was the machine itself and cleaning every part I could take off...). Here's an example without the belt (it sounds louder in the video than it really is): And here is the noise it makes with the (old) belt. New belt sounds roughly the same. The noise I mean is the CHWUNKWUNKWUNKWUNKWUNK sound. I'm fine with a bit of a whirr from the motor, but this doesn't sound good. Things I've already done: - cleaned and lubricated the whole machine - aligned the wheels of the motor and the machine - tried a different (75mm) pulley instead of the 50mm pulley - replaced the belt - varied the belt tension Alas, it still makes the noise. Does anyone know what could be the cause of this? I found this other thread but but his videos are not available anymore, and there is no solution posted. Thanks! - Hidde

-

Just installed the servo, it came with a 75mm installed but also with a 50mm pulley. Of course I immediately swapped in the 50mm . Here's a test on the slowest speed, I'm very happy with how slow it is!

-

I have collected a few manuals, as well as the parts lists of the 145 and 545. This particular issue is not mentioned as far as I can tell. Good tip to try the 1245 manual as well! Next issue: missing parts. The spring and tension disks on the tension assembly were missing (see below). I've now snatched the spring and tension disks from the bobbin winder and installed those onto the tension assembly. It works, but I'll still have to order the correct parts, I think. At least I can sew in the meantime I'll probably end up ordering a whole new tension assembly (part number 91-009 328-91), I don't think I can find the individual missing bits. After winding my first bobbin I've now also sewed my first stitches, which didn't look bad at all! Unfortunately the machine has a 2850rpm clutch motor, and it runs off at a million miles per hour with the lightest tap on the pedal. I'm getting a servo later this week, hoping that slows it down a bit!

-

This turned out to be the issue. I've increased the distance between the circled parts and now the bobbin only spins with the axle (I have no clue what the actual names of all these parts are lol). Super obvious in hindsight but as a noob I didn't think of it before! Just wound my first bobbin!

-

Greg, does the bobbin spin freely when you put it on the bobbin winder of your 545? Mine does, and I don't think it's supposed to.

-

That is indeed the angle - it's not touching the belt, but it's awfully close, so I might move it a little farther away. Thanks for your reply!