bluekush

-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by bluekush

-

-

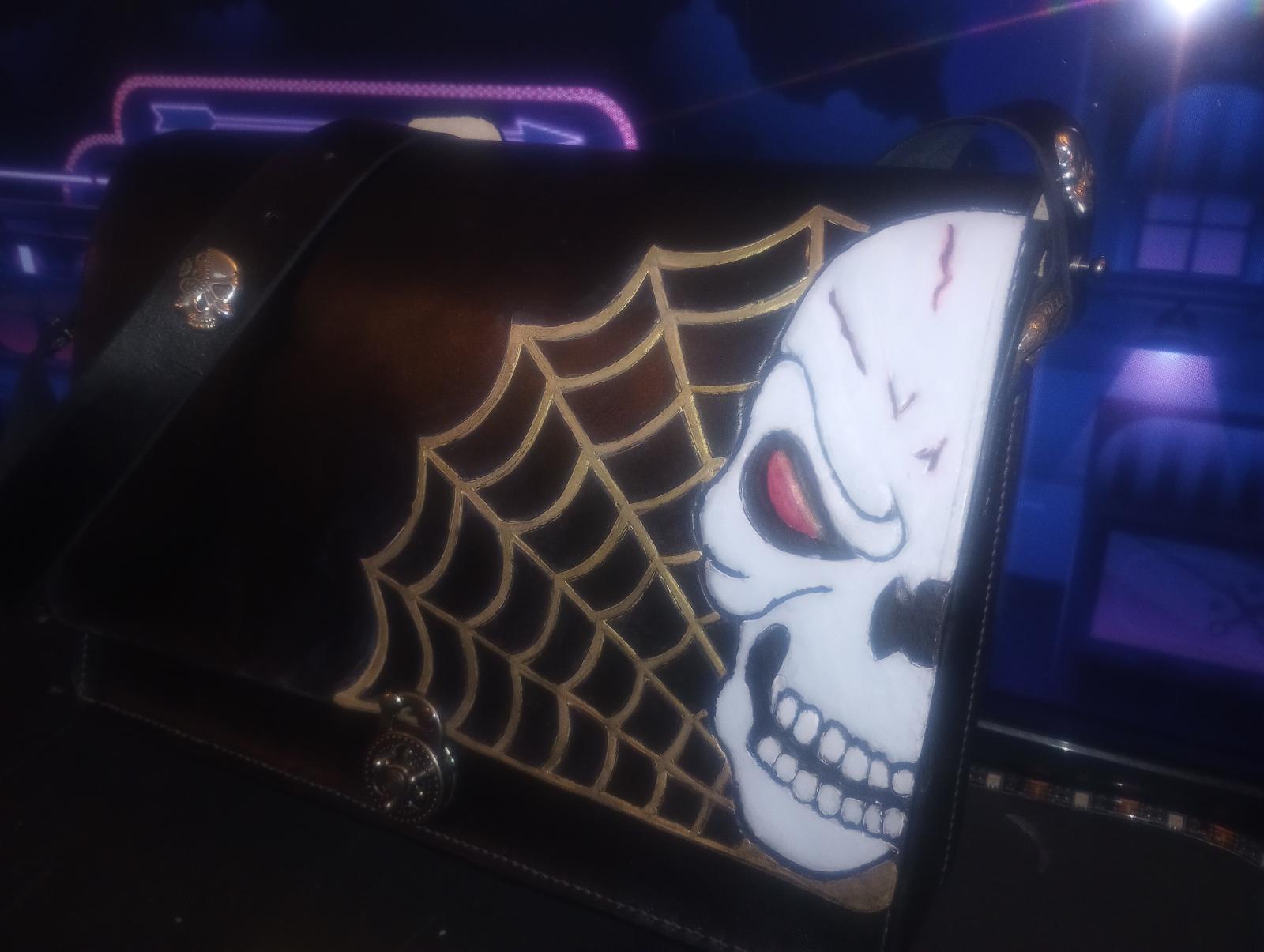

Can't pick what colour to make this bag. Black with red roses and green stems, or brown with the roses just antiqued or coloured red and green, or all red with the roses antiqued black.

-

I've been leather crafting since February and this is the first project that I'm really happy with the results. It was also my first time tooling, I'm going to try something more detailed next.

-

8 hours ago, Deanr said:

Did you paint your edges before sewing? If you have a belt sander you can use a finer grit and sand the excess off, then refinish your edges. Just remove enough so both edges are flat. Use a beveler after sanding. Then burnish the edges together.

As mentioned before when using contact cement, make sure you let both pieces air dry before pressing together. Depending on the application sometimes I use basting tape instead of cement. Doesn't hold as well but is alot easier.

Yes I did paint and burnish the edges before sewing is that not the order you are supposed to do it In The pattern pack told me to finish all dye and painting before stitching.

Yea it was like tacky dry maybe I didn't wait long enough. If I take the thread put and try cementing it before stitching will it come out better or is just because of the way it cut and finished the edges already? I was thinking about undoing it and adding a piece of leather in the middle, I think its called pipping ? Not to sure. I've already took it apart once so I don't really want to do it again.

-

7 minutes ago, TonyV said:

lf it were me, I would decide that this is now a practice piece. Looks like I could carefully trim off the overhang witha very sharp knife, then very carefully sand it as smooth as I could. Will take some patience.

Then I would slick the edge and decide if it warranted any more judicious sanding. You might get away with trimming and sanding, but you might not. I would anticipate having to make it again, learning from my mistake.

Next time cut the edges together, as if they were 1 piece. Leaving a little bit of extra trim space and gluing them together, then making the final cut of both pieces gives a great result. Then make your stitch groove, chisel and sew.

Thanks for the response. It's all practise at this point as I'm only a month or two into the craft. Im making this for my girlfriend, she doesn't seem concerned about the imperfections but they do bother me.

I traced and cut this from a pattern pack so I would have to change the dimensions to cut it after, I made my phone case that way so I understand what you mean.

I'm going to try cutting sanding and burnishing the edge. Hopefully it works well.I had a really hard time using the contact cement. It wasn't sticking at all when I tried on a sample piece so I just went without.

Anyways this is my first project like this and I'm pretty happy with how's it's coming out and I know the next one will be better.

-

I was thinking either sand it down or cut it off but I'm not sure how it's going to look after. figured i would ask here for some advice.

-

4 hours ago, Hags said:

I use a knife, sandpaper, then water and saddle soap. I use the bar soap I get at a local farm and ranch store. If you don't have a wood slicker, try canvas or denim. The ieather you use matters as well. Chrome tan just won't slick up as good as veg tan. An inexpensive box knife can be stropped and cuts very well. I use a box knife for large cuts like belt straps out of 8/9 oz, a #5 xacto for smaller cuts, and a 60mm rotary cutter for lighter stuff. You will aquire things/tools as you go. I'm always on the look out at garage and estate sales for old leather working tools.. Good luck.

Thank you I made a trip to Tandy today and bought a wood slicker and burnishing solution an edge beveler and an xacto knife set, and a couple patterns I'm going to try making a bag but first I'm going to do some research and watch some videos to get an ideal of what's required before I start.

A rotary tool you say, I have that I'll give it a try.

-

13 hours ago, Mablung said:

Read lots of threads about “burnishing” and “slicking”. Right now I focus on making my edges uniform with knife and sandpaper, then slicking with water on the edge and a wooden burnisher. Other methods produce better results; I’m just focused on getting those couple techniques down. There are a lot of good resources, too, and there are some search tips somewhere around here for using Google to search this particular site more efficiently.

Awesome thank you so much this sent me down the rabbit hole I needed to find.

-

3 minutes ago, Hags said:

Looks good. You could pay a little more attention to the edges.

100% I actually don't own a beveler yet, and the first couple I made used this circular pizza cutter thing? It lost its sharpness very quickly after seeing some of the posts here I'm excited to try my hand at some things like a knife sheath I'll try to get some nice edges on it. Any tips or products you guys use to get that sheen on those edges?

35 minutes ago, Northmount said:Hi @bluekush Good work. I'm a fellow Calgarian. Looking forward to seeing more of your work.

Awesome man. thanks I appreciate it

-

26 minutes ago, Mablung said:

How long have you been doing leatherwork? That’s a great set of stuff.

I was gifted a couple tools on Christmas but didnt get around to making stuff till I bought some leather and additional tools in February these where the first couple of things I've made since then

-

Hello I'm new to the world of leather crafting and was looking for a place to show off/ learn how to get better.

Help me pick a colour for this purse

in Leatherwork Conversation

Posted

I think I agree that red or brown with antique is going to look best for this piece, mahogany might be that nice inbatween thank you