-

Posts

24 -

Joined

-

Last visited

Profile Information

-

Location

Europe - SLO

LW Info

-

How did you find leatherworker.net?

With searching about 29k

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Bosko90's Achievements

Member (2/4)

-

I can try it with a thicker one. But I can confirm that it can be adjusted so tight that I almost can't pull the thread out with my hand.

-

Thank you for the detailed explanation and the attached photos! They’re always helpful. I think all of these things are set up the way you described, as I’ve gone through everything many times. That’s why it frustrates me even more — I really don’t know what else it could be. The shuttle hook isn’t that expensive, but I wanted to be sure it’s the actual issue before buying one, and whether this Chinese one would even be okay. You mentioned the take-up spring. It seems quite strong to me, but it’s originally much stiffer than what we’re used to with other sewing machines. I tried to loosen it as much as possible. The only thing I’m not sure about is the correct setting for its height (or how long its range of motion should be).

-

Hello. Some new information, but still no solution. I have a friend who owns an Adler machine that's almost identical. We swapped shuttle hooks. Mine fit into his machine with a bit more clearance. He slightly adjusted the spring into a more correct shape, and it worked well—it was stitching nicely. His shuttle hook fit into my machine a bit more tightly. It had very little clearance, which caused the lower thread to jam frequently. However, as far as I could test, my machine was able to sew 2mm thick material. When I put my shuttle hook back (the one with the adjusted spring, which worked fine on his Adler), it still doesn't work on my machine

-

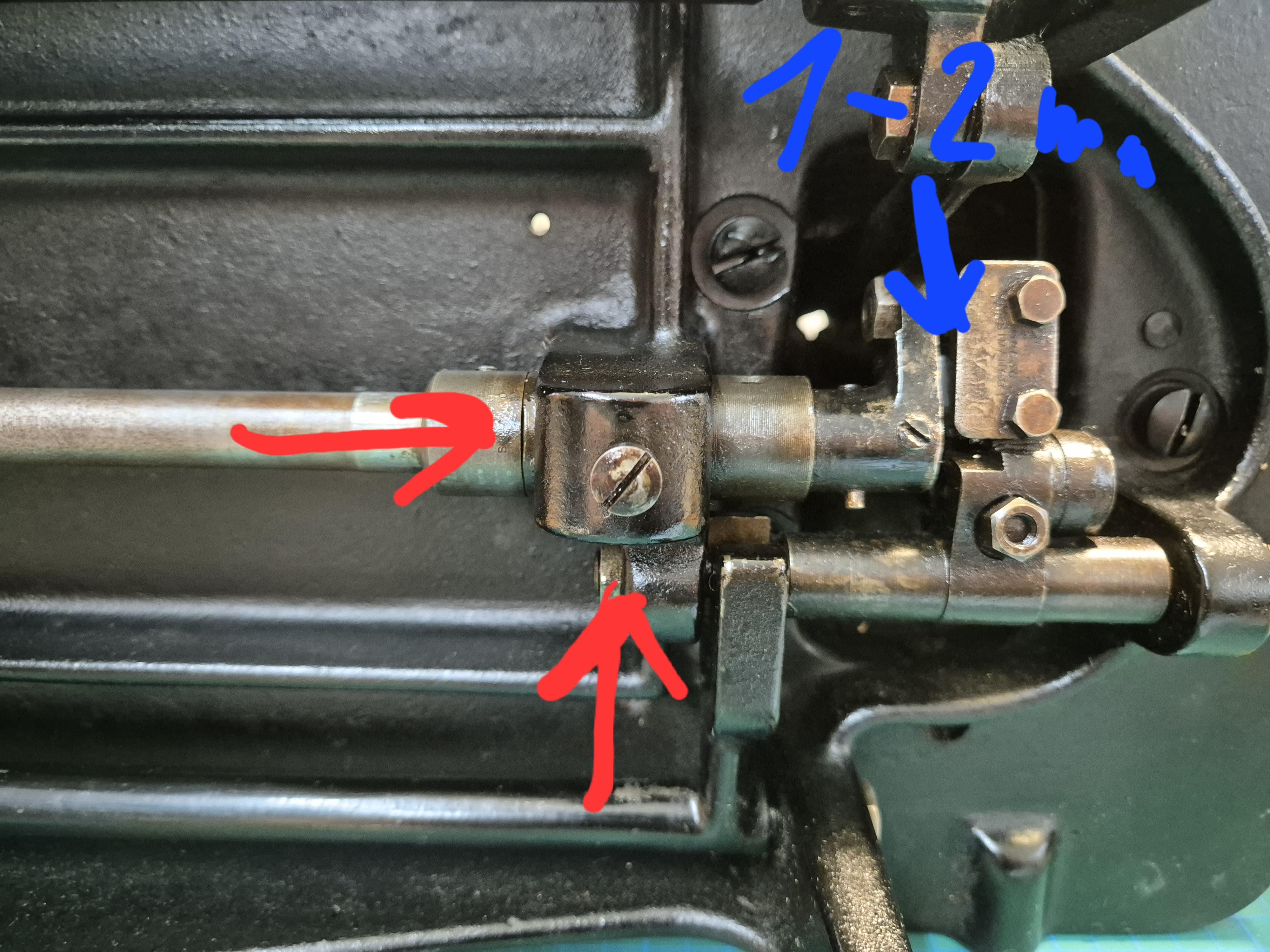

@Constabulary I have made thread guide (For now is copper, but I will make from stainless) @shoepatcher I hope I can find new one. It would be niece if this caused problems. You are second person who notice these gap.

-

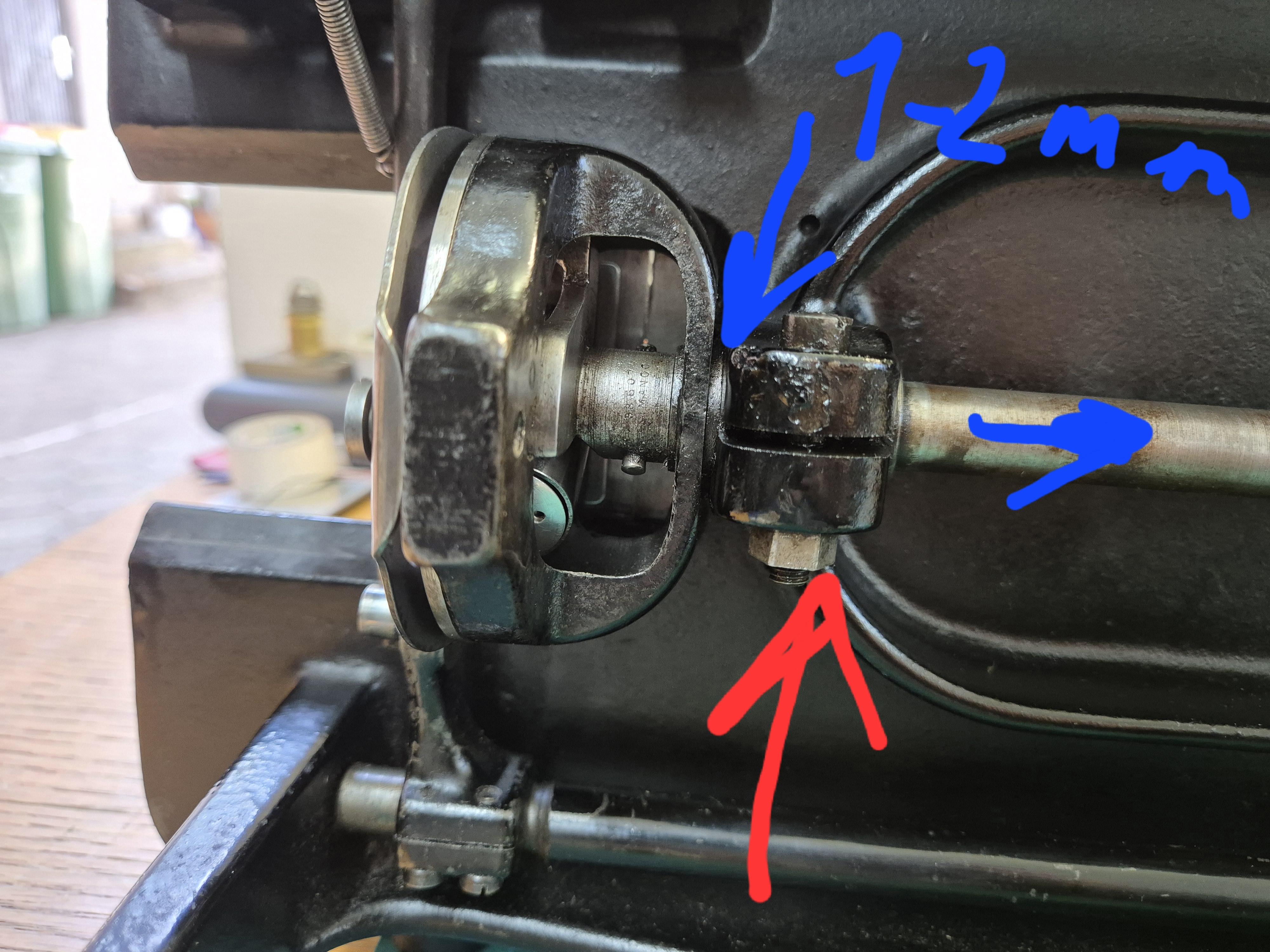

This one doesn't have a lock screw, but I know yes, some have it. I tightened it practically all the way and there's no difference. Do you mean this gap? Hmm, maybe the spring is really bended. That must be flush with housing?

-

One more video. Focus is little bad it is hard to have phone in one hand and spining machine.

-

Ok, that's what's missing. But I don't think there should be any problems with that, or? I didn't check the timing specifically because it's grab thread, and I don't even know the exact position for this machine, what it should be. There is one thing that is still wrong and I can't fix it, that's the only thing I suspect could be wrong. The hook goes too close to the needle and it slides on it. I recently got about 40 needles, all of which are worn down to the point where they have a bit of a flat surface on the side. The needle I'm trying with is new. I tried to move the entire lower system, but it was unsuccessful, probably the corrosion was too strong.

-

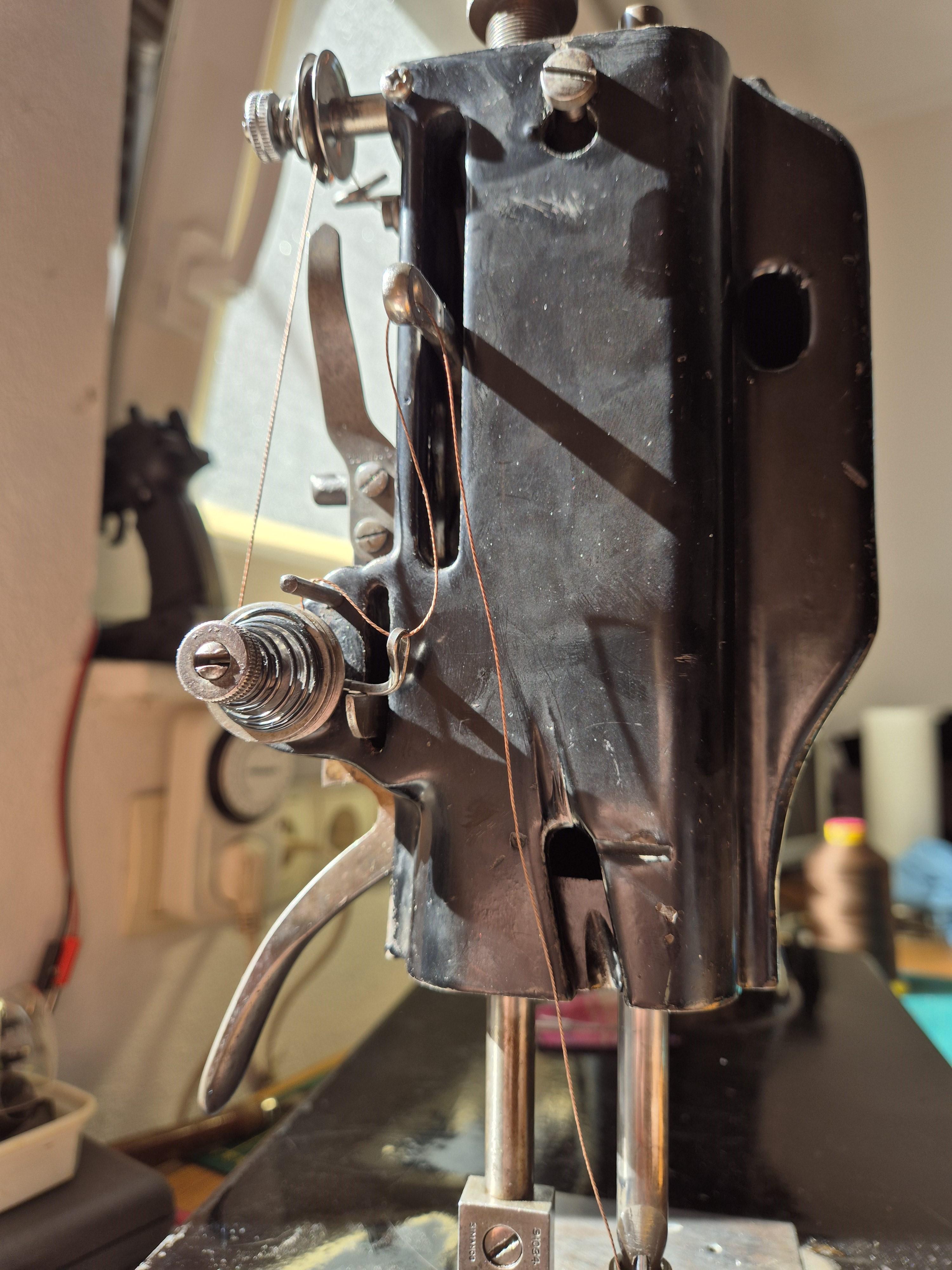

Hmm through the eye? No, but it would be possible for the needle to go through the thread. I have a friend who has an Adler 4-2, at the first opportunity, we will try it with his shuttlehook. ok was uploaded to yt. And here are some photos. In the photo you can see the moment when the lower thread becomes very tight and the thread is pulled out of the bobbin. This is the moment when the needle is in the completely lower position. At that time, the upper thread is completely relaxed and does not affect the lower one. In the second photo, the appearance of the upper thread at the same moment. In the last picture we see how a slight loop is made on the lower thread. This is at the moment when the upper thread starts to pull upwards. It pulls until it uses up this excess thread. And this is at the moment when it already looks out of the 2mm leather. This way, the lower thread offers absolutely no resistance to pulling, no matter how tight the tension screw is. And as I mentioned before, if I lightly press this loop against the bobbin case with my finger to hold it in place, it makes a nice stitch.

-

Both are fine. I feel like it works properly, because I can adjust it from completely loose to so tight that I almost cut my fingers when I pull the thread. And on last time I trying to sew, I had it so tight, and there was absolutely no effect on the stitch. As I said, the lower thread is somehow pulled out so far that when the upper thread lifts it, it goes up so far that it peeks over 2mm of leather. If I hold it down with my finger slightly by pressing it against the bobbin case at the moment the upper thread starts to pull, it makes a nice stitch.

-

Here needle is at the lowest point, uper thread is lose and check spring have no function at that moment. If, at the moment it starts to pull the thread up, I lightly press the lower thread, which is too much, with my finger, it makes a good stitch.

-

Sadly no effect when I tighten check sping.

-

@Wizcrafts I loosened this spring, hoping it would help. so can I tighten it? I'll try. @Constabulary I used thread 20 (138) and needle 160 LR (23). I'll take a picture or video if anything shows up. 20250307_123416_1_1.mp4 When it goes counterclockwise (needle goes down) it pulls too much thread out of the bobbin. When it goes clockwise (needle goes up) the lower thread becomes loose and the upper thread easily pulls it so far that it peeks out at the top of the leather.

-

I don't know why my topic disappeared, so I'm writing again. So my problem is: I got realy niece singer 45k5. When I try to sew, upper thread pull bottom one to the top. I know in most cases these is tension problem. But I have upper thread totaly loose, almost no resistance and bottom thread have so much tension that I realy hard to pull out by hand. After watching hook 100 times I saw, in the moment when needle go down, pull too much thread from bobbin. And when upper thread pull up the bottom one, there in absolutley no resistance on bottom thread because it have big loop, until the thread looks out from the top on the 2mm leather. So setting the lower tension has absolutely no effect whatsoever. I hope someone can help. As Wizcrafts sugest, I check all thread lines and all is threaded correct.

-

eddo it's been a while, how is the machine? Does it work? Did you find a solution? I have the same problem now. I got a singer 18-3 machine for free which was fully functional but has been sitting in the rain and snow for the past 2 years. Now I can't release the needlebar and foot lifting bar at all. I've been soaking with WD 40 and heating with a torch for a week

-

Yes, I mean grinding. English is not my language. I was fix that shape and all parts is inside of needlebar diameter. But I don't know if the spring is strong enaugh. It is much weaker than original.