Search the Community

Showing results for tags 'chandler 305-64'.

-

Second post, so far I have learned a lot, just by lurking before I joined. So here is the scoop, I came across a Chandler 305-64, understandably just a re-badged Adler 105-64 ( I researched here before purchase). The machine is in great shape for being roughly 30 years old and I am the second owner of this machine in this time. The previous owner, the U.S. Navy, purchased the machine brand new in 1987 at a tune of $3721.00 (it has a brass placard on the back with all the information). As with all military hardware, it had a functional 'Hour Meter' attached to the table...showing only 465 hours....so 15.5 hours a year (average use) is not bad in my book. It is complete with table and the dreaded clutch motor. The only damage I found was that the thread reel pin on top of the machine was sheared off. It took me a few minutes with a small drill bit and an easy-out to remove the threaded stub. I contacted Durkopp Adler about a replacement...needless to say they are 'proud' of their parts!! At a cost of $97.00, I think I can fashion one up on my lathe and mill and have some change in my pocket afterwards! I am currently refurbishing the table, as it was stored in a warehouse and had not been taken care of at all. After a good cleaning and a bit of oil, it turned smooth as silk. I didn't have any sewing machine specific oil on hand, so I oiled it with some oil that I use on my vertical mill, oil that is used for the precision ground matched bearings in the mill. I figured if it was good enough for precision bearings, it ought to be good enough for a German-engineered machine....please correct me if I am wrong? I will pick up some oil specifically made for sewing machines. I came with only one foot, looks like a right cording foot and have contacted Bob at Toledo Indust. Sewing Machines for replacements...at least he has a regular foot in stock and should get me started in the right direction.I have a line on a servo motor to replace the clutch motor but will wait until I finish the table refurb until I purchase it. Being new to leather, I have a few projects lined up, mainly dog collars, as we foster and rescue Belgian Malinois. I would like to be able to send them to their new home with a piece of me...a new collar as they settle in to their new homes. I may dabble in a holster here or there if my skills progress to the point I am not wasting material. So, experienced members, if you could possibly shed any light on the pros and cons of this machine,it would be greatly appreciated. Seeming that I mainly use my Singer 20U for most of my projects, the fan-dangled cylinder arm machines are all a new beast to me! Any help, words of wisdom, or criticism is greatly appreciated. Here are a few pics after moving it into the sewing room. Thanks in advance. V/r, Chayse Another angle

-

I figured I would start a new 'thread'...no pun intended! I am in need of some assistance with threading my machine. I do have the manual, although a bit confused. The manual covers the 104 and 105 series but what is confusing, the 104 looks to be a 2-needle machine. Do I follow the threading procedures for a 2-needle machine even though mine is only using one? Does it thread like the 205-64, looks as if they are roughly the same, although the 205 has a walking foot? I will revisit the manual and study it a bit harder...right now the coffee hasn't kicked in and am just a bit confused about it. Thanks in advance! V/r, Chayse

-

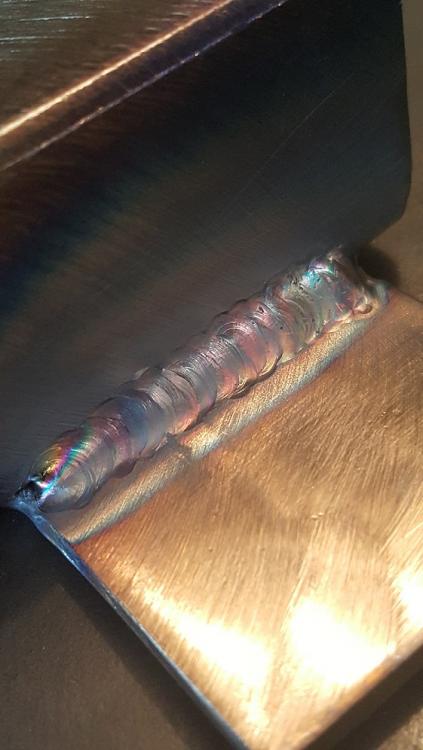

So I found some time to get to work on my table for my Chandler 305-64 cylinder arm machine....which is rare..just due to the fact that I have many projects going on at one time. Here is a pic of the table how I got it..typical formica and the previous owner had cut the table for some reason, which caused the table to tilt, given the weight of the machine when mounted. I knew I had to do something, so I first ditched the formica for some birch, which is 1.5" thick. I cut, sanded, routed,, and then finally stained and added a couple of coats of poly for protection. Here is how I got the machine.. I dug through my scrap and found some 1" tube and cut it to length. I choose to tig weld it for the sole reason that I haven't done it for a while...and it shows! I definitely need to get back to tig welding because it is relaxing and I truly enjoy it. I set out to fab up an outer support with adjustable legs or feet. This is what I have come up with and thought I would share. The tabs are 1/8" stainless that I had laying around...also from the scrap bin. When welding plain carbon steel to stainless, 309L filler is your go to material!

-

I have begun to finish up cleaning and repairing my Chandler 305-64 (Adler 105-64 clone) and I am faced with the issue of having only 1 presser foot! Seeming that the original Adler presser feet are prohibitively expensive...I am at a loss. I either work with what I have or possibly sacrifice my only foot so that it will except more available foot options. I have looked and have found close substitutes but it would be a roll of the dice if they will actually work or not. I have attached several pictures of the foot that I currently have and I know that there has to be different presser feet for this machine that will work...hoping not to spend an absorbent amount of money for different foot options. They have literally cloned everything when it come to sewing machines...why not feet for this machine. I have thought of casting different feet or possibly trying to fabricate my own on my mill. Then again, i could modify the only foot I have to accept different feet from other machines that are not so expensive. I would basically cut the foot portion off the 'shank', mill it so it is as close to horizontal as I can (hopefully within a few ,001's) and attach more common presser feet. Basically, I am asking the knowledgeable folks here on how I should proceed....so let's hear it...at this point...I only have one option without modifying the only foot I have....