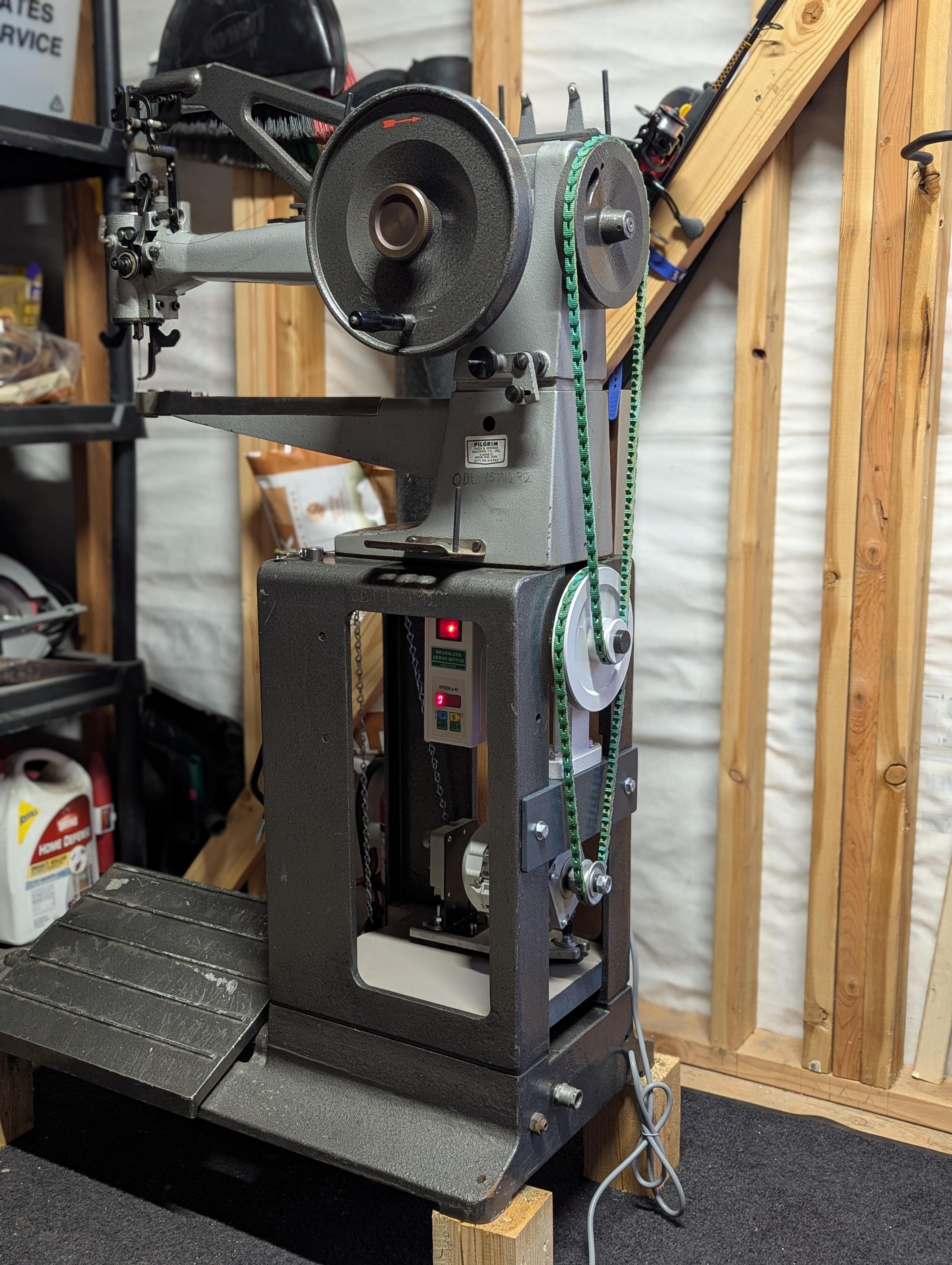

My Consew's servo has a min of 400 rpm and I have the smaller pulley installed. If anything a needle positioner would be nice on this machine. As for the Claes I think I'll get a speed reducer to really slow it down.

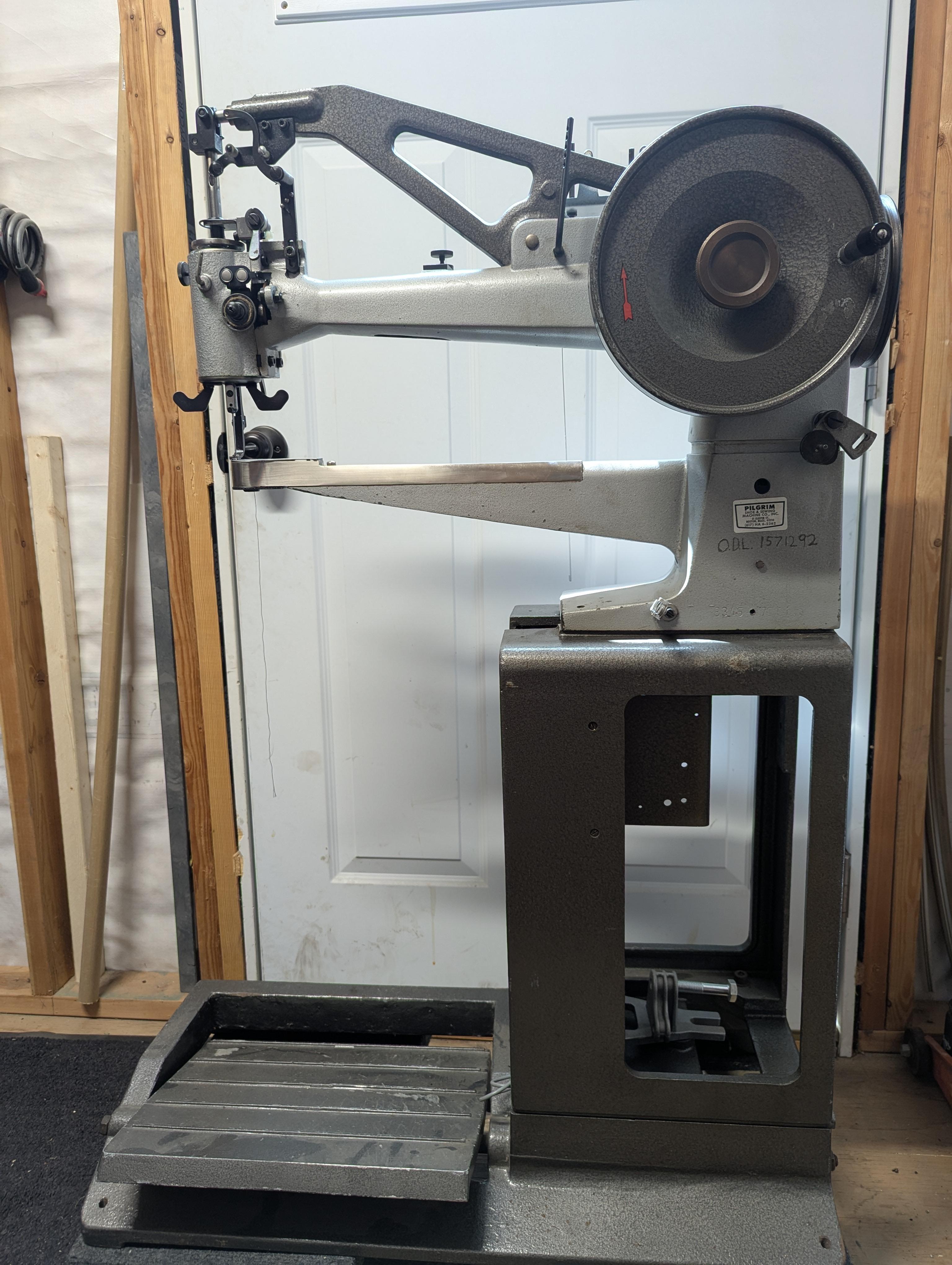

Yup, thanks for the correction on model number. For some reason I've been transposing the 3 and the 4 ever since I first read about this model. I can't find a way to change the title or I would...

I'm sure you're right about boot soles. I don't really have any goals with the machine other than to be able to get into tight places for boot and backpack repairs. If it did soles that would be a bonus but not a deal breaker.

Thanks for the link, that manual seems to be posted on a few websites. I also have a document with drawings of individual components but that one is in German. I've seen posts regarding a mechanics manual but I can't seem to find one posted online.

Hopefully you're right on the adjustment. We'll see what everyone thinks after looking at the video.

No worries on the sole work, just brainstorming what things I may attempt to repair.

Yup, I think slowing the machine down to a crawl would beneficial than a positioner.

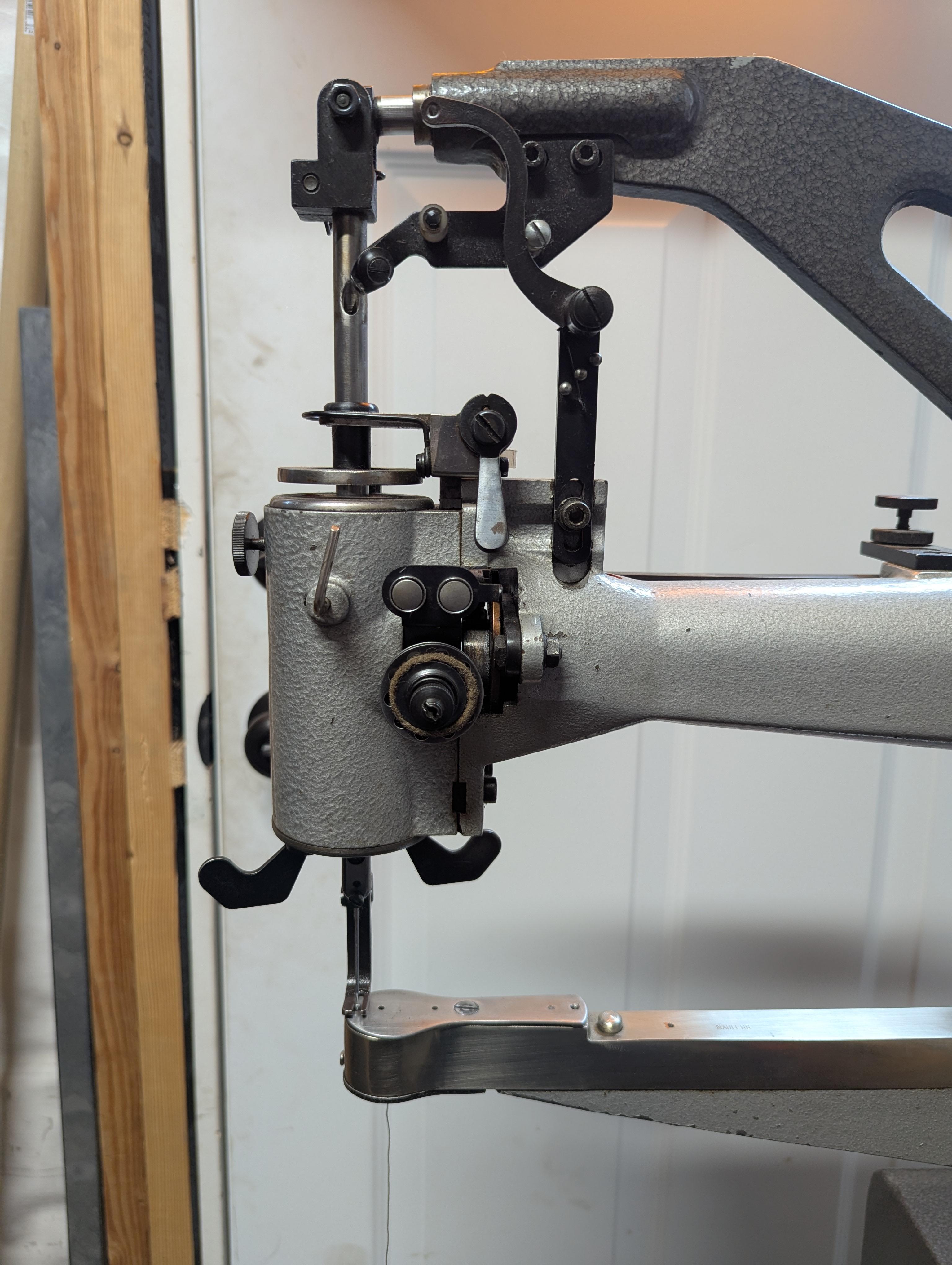

It came with a couple dozen 88 needles, I didn't see any 81s in the batch.

Here's the uploaded video. Along with the needle timing I'm also concerned about the horizontal play in the main shaft. You can hear it "clunk" into place every rotation.

Here's the Youtube link, hopefully it's good enough: