Stagesmith

Members-

Posts

11 -

Joined

-

Last visited

Contact Methods

-

Website URL

https://www.flickr.com/photos/129065511@N02/albums

Profile Information

-

Location

Renton, WA, USA

-

Interests

Tools for everything

LW Info

-

Leatherwork Specialty

Knife Sheaths and holsters

-

Interested in learning about

Using a commercial leather sewing machine

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Stagesmith's Achievements

Member (2/4)

-

Just got a Consew 255RB. It needs an oil pan.

Stagesmith replied to Stagesmith's topic in Leather Sewing Machines

I decided I'm going to use the table as a form and vacu-form a plastic drip pan into the opening. I already have an industrial vacuum pump in the leather area for vacu-forming leather into 3D shapes. I'll block off the underside of the opening, make a plywood frame around the opening to restrain the sheet and just heat the plastic in place with heat guns. Hit the vacuum pump and suck the hot plastic into the opening. Should work great, and I already have everything I need to do it. -

Just got a Consew 255RB. It needs an oil pan.

Stagesmith replied to Stagesmith's topic in Leather Sewing Machines

There is an oil reservoir in the top of the machine. Running the machine feeds oil through multiple internal lines until it drips off the bottom of the machine. It really is an industrial machine. -

Just got a Consew 255RB. It needs an oil pan.

Stagesmith replied to Stagesmith's topic in Leather Sewing Machines

The Consew part number is #15080. I can find a few listings for it but nobody seems to actually have one. it is a full pan not a drip tray. The 206RB is just a tray, but the 255RB is more like a gas engine oil pan. -

I just got a Consew 255RB and I'm trying to get it set up, but it uses an internal oil system that requires an oil pan to catch the run off. I can't find one for this machine, but since everything is a copy of a Singer I'm wondering if there is another pan that would work. I'm seeing lots of Juki pans on eBay. I have a metal fab shop and could make one from scratch, but it's going to take a while to fabricate that shape. Also the real ones have the pass thru for the knee lifter. Any help would be appreciated

-

Micro Copper Burr Rivets - A Solution

Stagesmith replied to Stagesmith's topic in Hardware and Accessories

The 2.5mm and 3mm washers do clinch onto the rivet shaft just like Burr Rivets. The 2mm washers are just a tiny bit too large on the ID, so they don't clinch, but I didn't find that made it any harder to use. If you bop the washer sideways with a tiny hammer, it can distort the hole enough so it does grab the rivet shaft. -

Micro Copper Burr Rivets - A Solution

Stagesmith replied to Stagesmith's topic in Hardware and Accessories

I found the set of doming tools on Amazon https://www.amazon.com/dp/B0D6724Z62 $30 is worth my time to just buy them. -

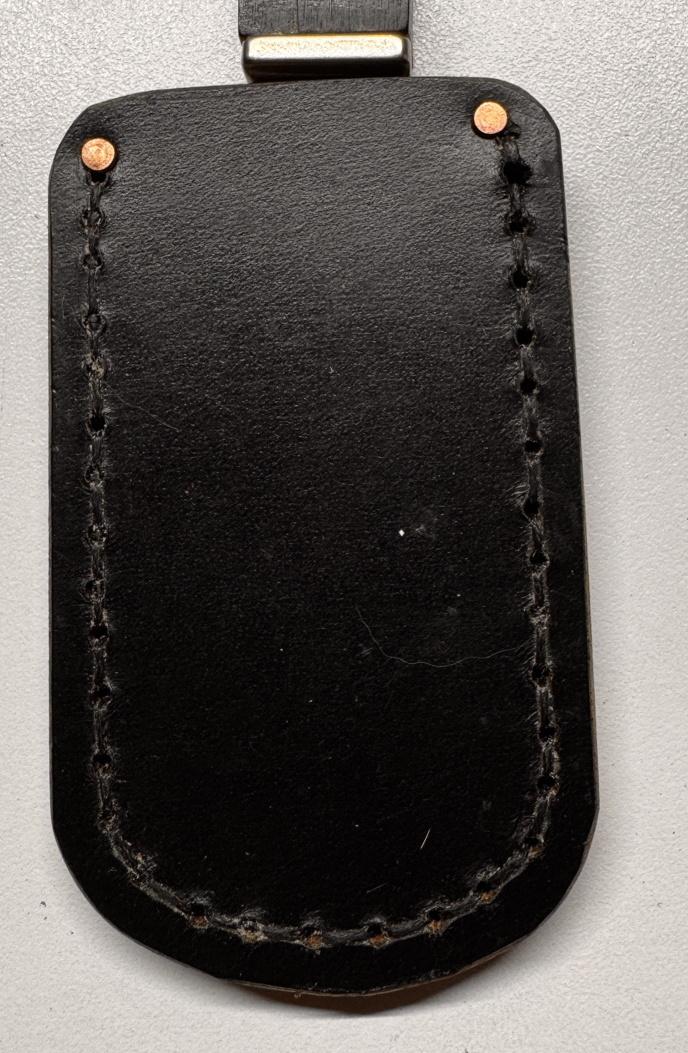

I mostly make leather knife sheaths and I was trying to find a compact rivet to end the stitch lines. I like copper burr rivets, but the smallest available are still way too large. I have found a solution that works for me. Amazon sells assortments of metric copper rivets in flat-head and round-head versions. The range is 2mm, 2.5mm and 3mm shaft sizes https://www.amazon.com/dp/B0CNCSHG3T https://www.amazon.com/dp/B0CNCT42XG I found the washers on McMaster Carr. They are sold as #1, #2, and #3 copper flat washers https://www.mcmaster.com/97565A111/ https://www.mcmaster.com/97565A112/ https://www.mcmaster.com/93661A112/ I made my own rivet sets by just end drilling some pieces of 1/4" round steel rod. You will need a #44, a #40 and a #31 drill bits. I think mild steel is fine as these will only get light use. I will probably make some matching doming tools by using a diamond ball bit in a dremel to carve little domes in some harder steel rod.

-

Home Depot does have them for $32. Definitely not US made. Wiss is part of Crescent Tools now. Using those as a base I could sell the Mega Leather Shears at $100 + shipping. I can't compete with China. That would cover my grind time and materials. Have to figure out a faster method of making serrations. I used a tungsten grinder with a diamond wheel for the prototype. I sacrificed a new, probably Chinese, pair for the prototypes. I'd feel a little bad using a nice older pair.

-

I can buy the new WISS 22W's for around $60 wholesale. Not sure where they are made anymore. Might be China. Older, better US made ones are on eBay for usually around $50 plus shipping. I'll make a few pairs and throw them on eBay to see if they get any interest. I like the set I made so much I just thought somebody else might like them as well. I thought about making fancier ones from the older HUGE tailor shears with the more elaborate handles, but there are not as many of those available, and they go for way more money if they are in decent condition at all. I refurbished a pair recently where the lower blade had split on the lamination line between the edge steel and blade body. They turned out pretty well, but I can't adjust the curvature of the lower blade without risking shearing the epoxy holding it together.

-

Greetings. I make tools, and have been making tools for over 40 years. I spent many months this year learning the skills of refurbishing, sharpening and tuning, tin-snips, shears and scissors. Along that path I discovered WISS #8 Belt Shears for cutting leather and fabric belting. They are very nice, but a bit small for my taste. The largest commonly available WISS Shears are #22W, at over 12 inches long They can be purchased new but the old ones are better. I ended up with several pairs of 22W's and decided to super-size the #8 Belt Shears. The WISS Belt Shears are interesting because the lower blade is serrated to hold the leather and the upper blade is knife-edged. My new shears cut 1/4" sole leather like paper. Kind of amazing. As a knife-maker these aren't too hard to make, but I'm curious if there is a market for them. I've been using these for the last few weeks on various knife sheath projects and really love them, but there are lots of ways to cut leather. I am curious what others think of these.

.jpg.d60258221c476480a6e073a8805645bb.jpg)