NowhereMan01

Members-

Posts

12 -

Joined

-

Last visited

Profile Information

-

Location

California

-

Interests

Sewing sail-related things

LW Info

-

Leatherwork Specialty

None yet

-

Interested in learning about

Sewing

-

How did you find leatherworker.net?

online search

NowhereMan01's Achievements

Member (2/4)

-

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

I got it working! It seems that the safety clutch got kicked out again, and when I finally snapped it back in place, the hook timing was way off (not sure how I missed any of that). Anyways, I adjusted the hook timing as discussed in the video below (which, btw, is a very similar machine to mine). It now sews. I probably still need to fiddle around with the safety clutch, as it seems to kick out before I get to the maximum stitch length, but otherwise, it appears to be working as well as it ever has in the (relatively short) time that I've owned it. Thanks again for all of the suggestions and help. This was a fantastic learning experience for me, as I now have an infinitely better understanding of how the machine works, and I believe that I should be able to keep it going for the foreseeable future... -

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

I've been trying to adjust the distance between the hook and the needle, and in spite of at least 25 attempts, I have not been able to get it to sew yet. Either the hook is too far away, and does not catch the thread, or the thread immediately breaks, and I get a mess of thread wrapped around the outside of the bobbin case. Any suggestions would be appreciated! -

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

I'll check that, but it looks to me like the timing is now correct, that is, the hook passes by the needle at the correct point. However, it is not quite close enough to consistently catch the thread, so I plan to adjust the "distance between the sewing hook and needle" (p. 19, Fig. 45 of the manual), and I'm fairly confident that'll get it working. Either way, I'll post an update here. -

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

Thanks! That diagram is very helpful. I loosened the end screws and was able to kick out the safety clutch, and get it to snap back into place (with the clear, distinctive sound that I've seen on YouTube videos). I don't have any feel for how tight it should be set, so I suppose it is safer to leave it at a relatively loose setting for now. The bobbin thread is still not getting picked up, so I'll post a video of that shortly. -

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

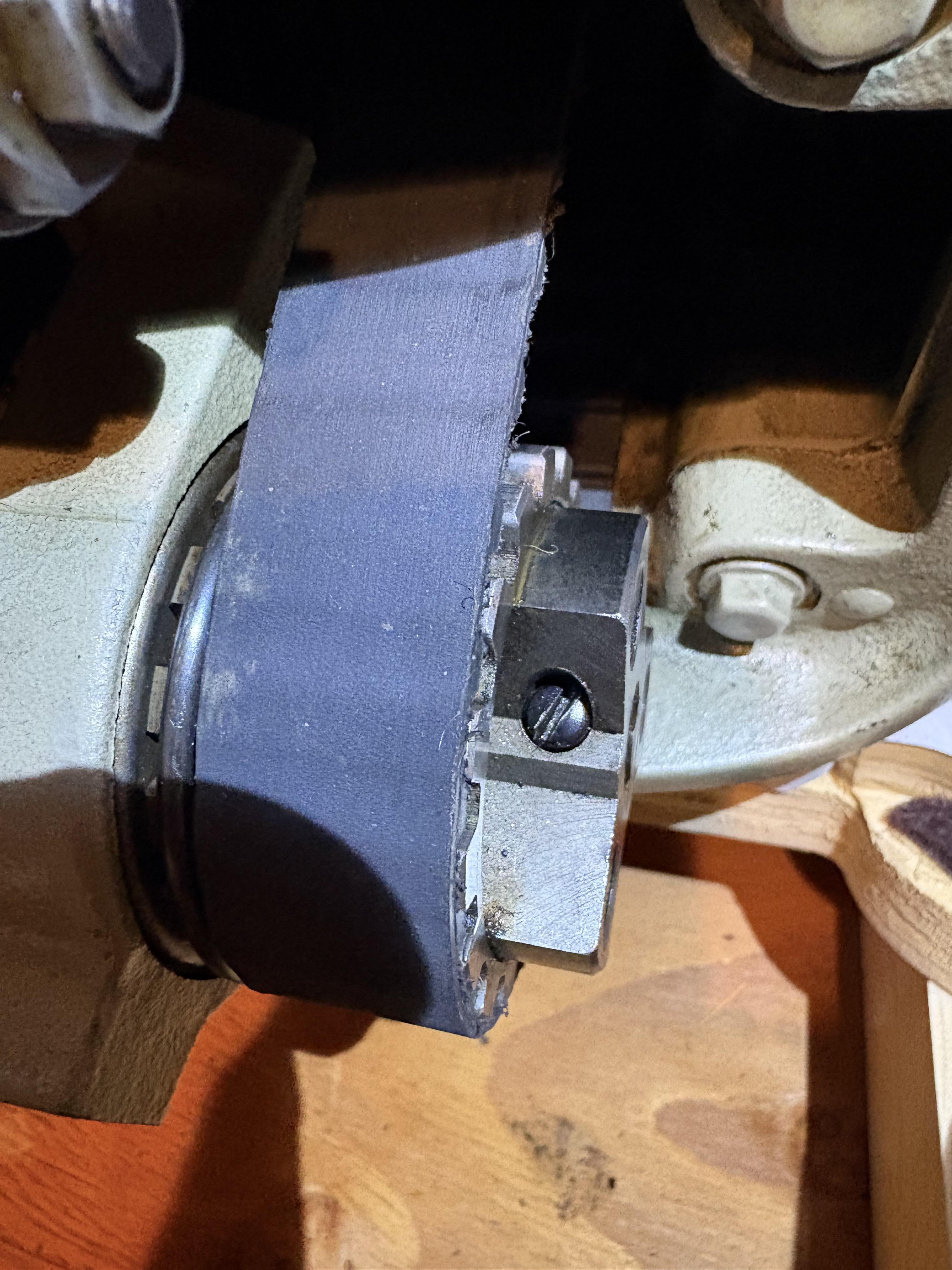

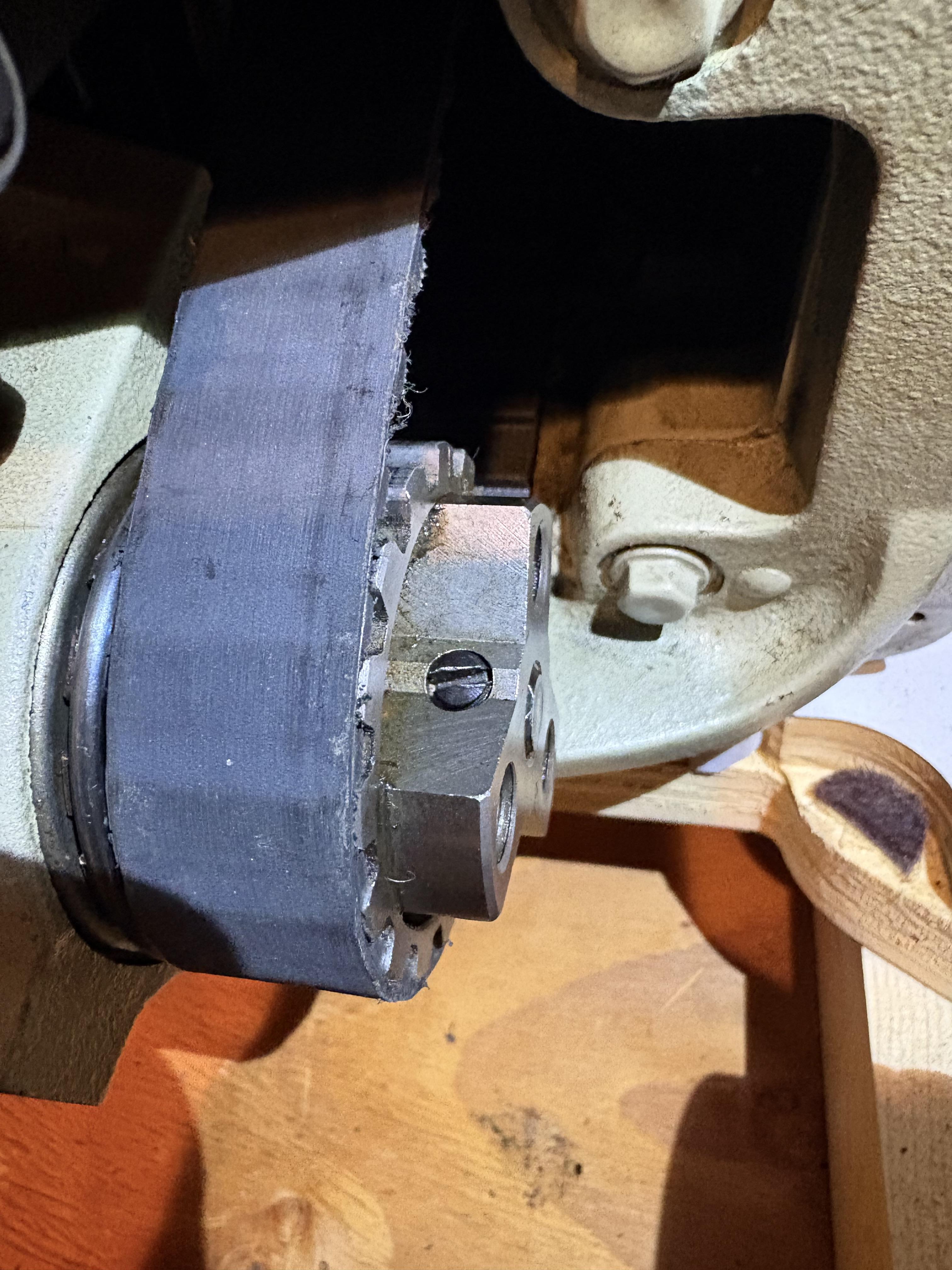

I will post a new-and-improved video of the bobbin, but I've been trying to figure out the safety clutch, and there does not seem to be much info on this particular style online, and I don't see it discussed in the manual. The 3 attached pictures show the 2 set screws and an end view. I assume that the 3 screws in the end view determine the force needed to disengage. The only picture of these in the manual (Fig. 65) shows them flush with the end, but on my machine they are turned all the way in. If my assumption is correct, I think I'll experiment with different settings to get a better feel for the disengagement/re-engagement. -

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

I really appreciate all of the help and I feel like it is very close to being resolved, but it's not quite there yet. Apparently, I did have the wrong set screw engaged with the V slot, and I've now got the slightly-rounded one in the slot. I also did the clutch engagement trick, and I did not hear a significant click (as I saw/heard on a YouTube video), but it did seem to have a small bit of "give" when pushed with some force, so it might have been out. Yet, the issue persists... Here is another video of the bobbin area, with me turning the wheel by hand. LMK if any other view might be helpful. -

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

Thanks! Although I don't see anything marked "S", there are 2 distinct screws on the eccentric that can be screwed into the slot. The first one I tried resulted in no stepping at all, but the other one seems to work, as it is now stepping, and the stitch length adjustment even seems to be within the correct range too. However, now the bobbin hook is not catching the thread, so I assume that something went out of alignment. Any hints/suggestions on what/how to adjust would be much appreciated. -

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

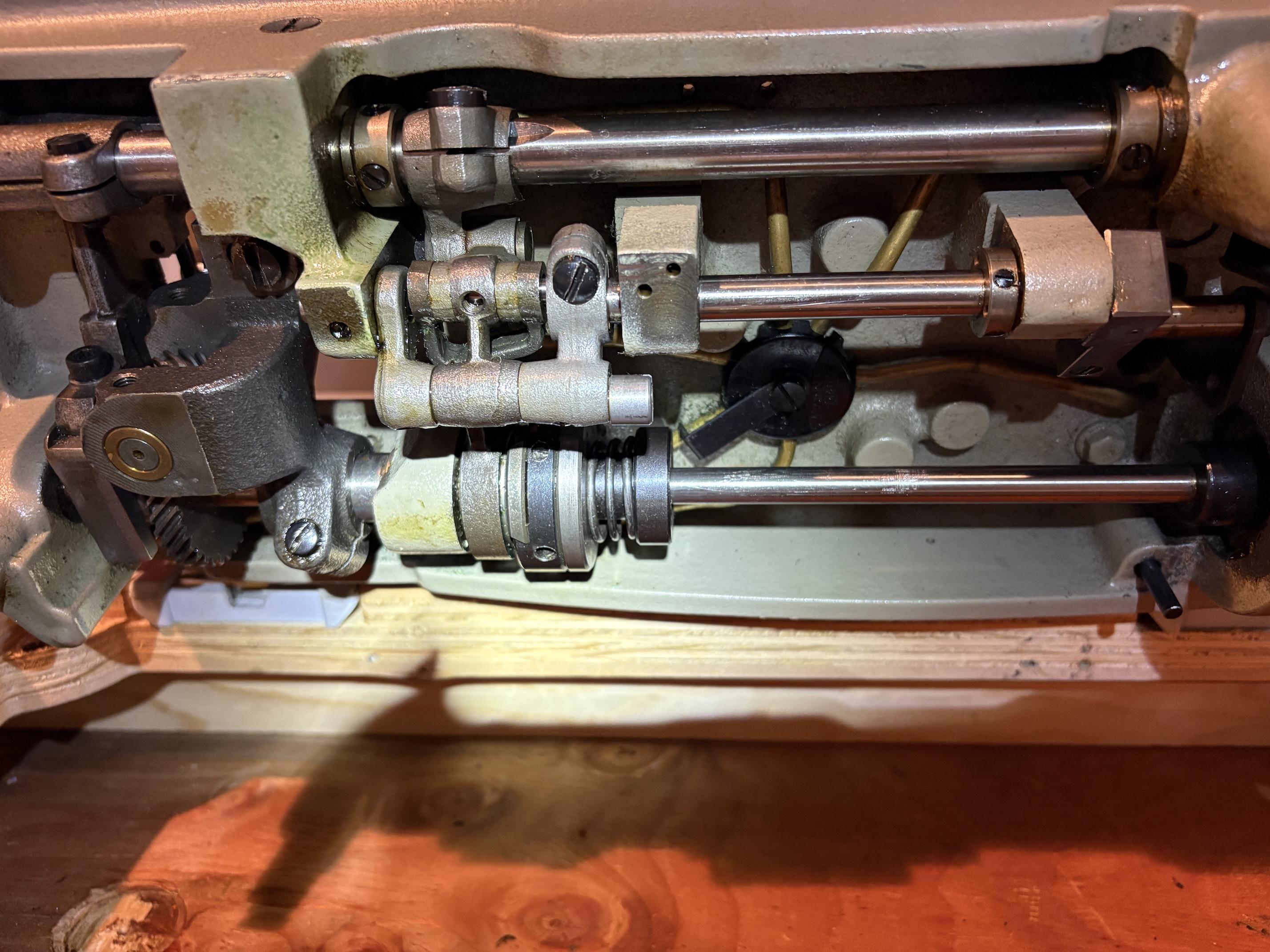

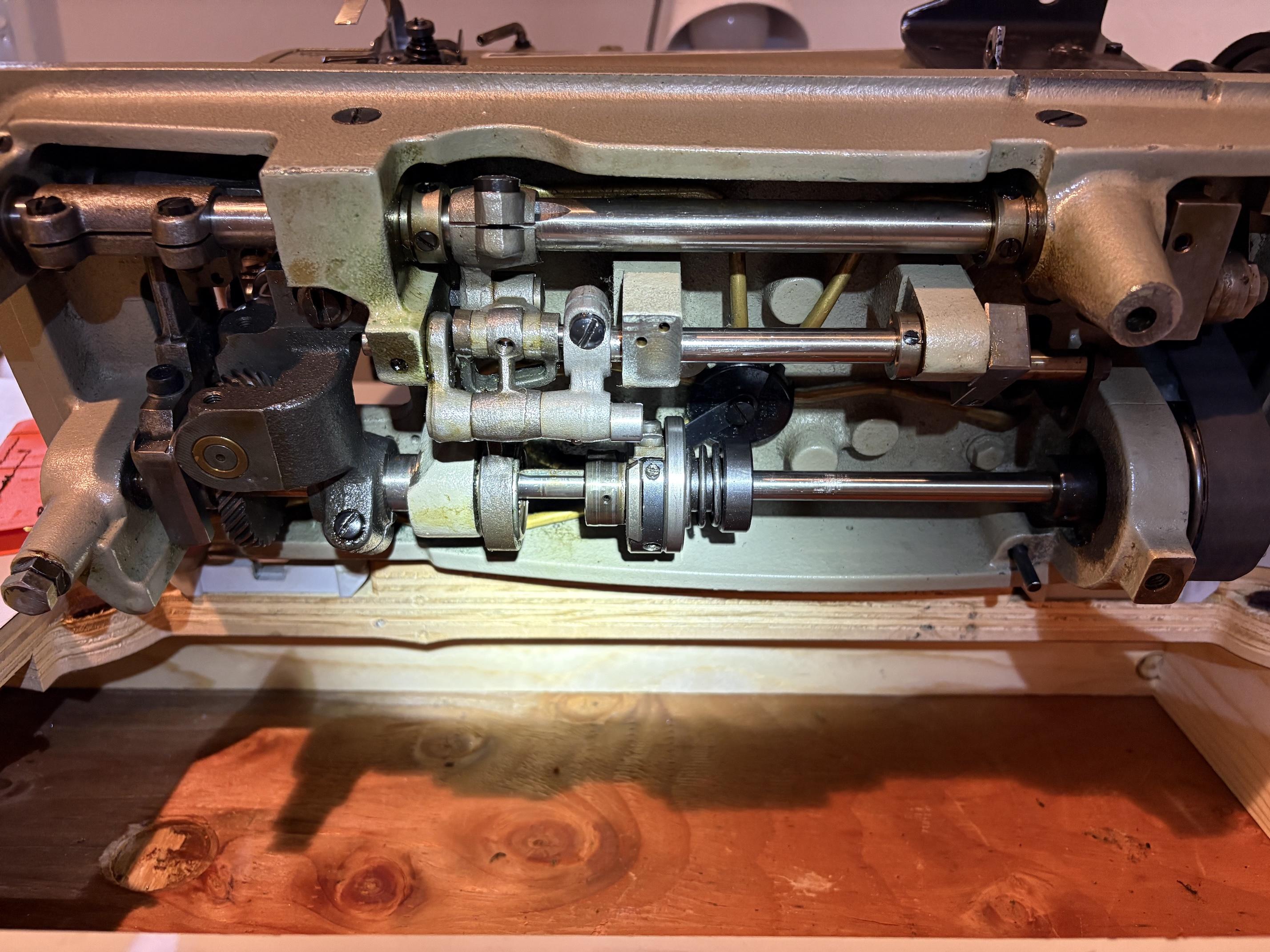

I actually removed the set screws that hold the spring in place, and it was a bit of a pain to get that put back together (had to compress the spring with wires). But, I don't think that has anything to do with the issue. The "eccentric" piece slides freely in either direction, so I can slide it back into place. But, when the rod turns (for example, when I turn the wheel by hand), the rod does not "grab" (or engage?) the "feed eccentric" piece at all, so it is not even possible to rotate it into position for the stitch-length button to be pressed. -

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

It looks like I spoke too soon. It did seem to "walk", so I tried adjusting the stitch length (still without thread, just trying to get a bigger "step"), and when turning the wheel with the button pressed, it seemed to have no resistance, and the results were very flaky. Sometimes it would walk more-or-less as expected, sometimes almost not at all, and sometimes it would even go in reverse (without the reverse lever pressed). So I started looking at the "Feed eccentric adjustment" on p. 24 of the manual, and that thing in the 2nd picture slid out of place, and doesn't seem to be attached to anything. Is it supposed to be like that? -

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

I think this solved the problem! Many, many thanks. I believe that what happened is that when it jammed (and I accidentally hit full throttle) the belt slipped. Now that I have aligned the "lower pulley" with "setting mark A" (as per page 26), it seems to be walking again. We have a heat wave here, and I don't feel like thoroughly testing it at the moment, but once I get around to it (which might take a week or so), I'll post here again, just to confirm... -

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

Thanks for the quick response. I'm not sure what you mean by raising the middle foot "by hand", but everything seems very rigid, unless I turn the wheel. Yes, I do have the manual, which can be found here: https://s3.amazonaws.com/a.teamworksales.com/SINGER+SERVICE+MANUALS/211U157A_165A_166A_566A.pdf The only thing I've found in it that looks at all relevant is on p. 25, "ADJUSTMENT OF THE LIFTING ECCENTRIC AND THE LIFT OF THE ALTERNATING PRESSER FEET". If there is anything else in it that I should be looking at, LMK. -

NowhereMan01 joined the community

-

I have a Singer 211U166A that I got for free, including table, servo motor, bobbins, and needles. I'm completely new to sewing, and the machine was not working when I got it. Fortunately, a local repair guy got it going, and I was able to sew several things with it--not leather, but some very thick, heavy, multiple layers of cloth (mostly, sailing-related). Yesterday, the bobbin got jammed, and my foot slipped, no doubt putting a lot of pressure on the drive, which resulted in a clunking noise, and a screw that connects to the reverse lever even fell off. I was able to replace the screw, but now the walking foot seems to not be walking. Specifically, the middle part of the walking foot stays pressed down on the fabric the entire cycle, and hence the cloth does not feed. I have posted a short video here: Any suggestions would be greatly appreciated!