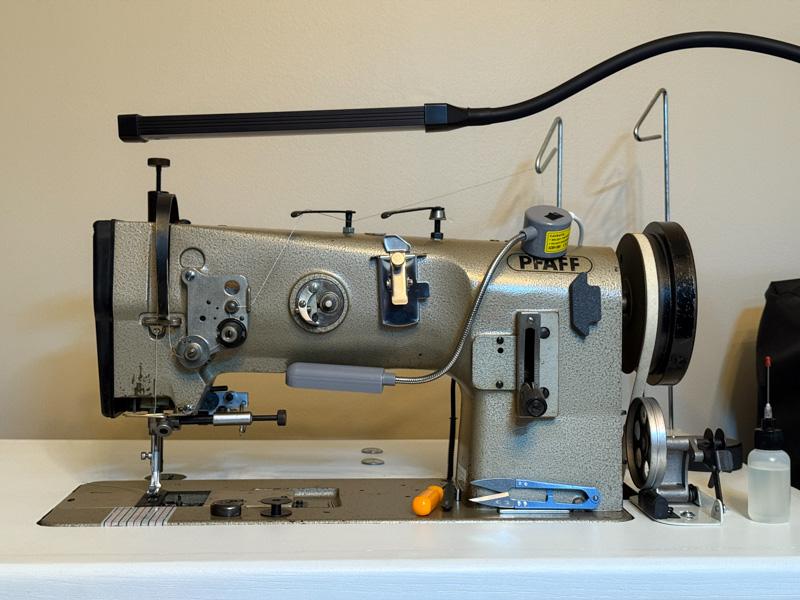

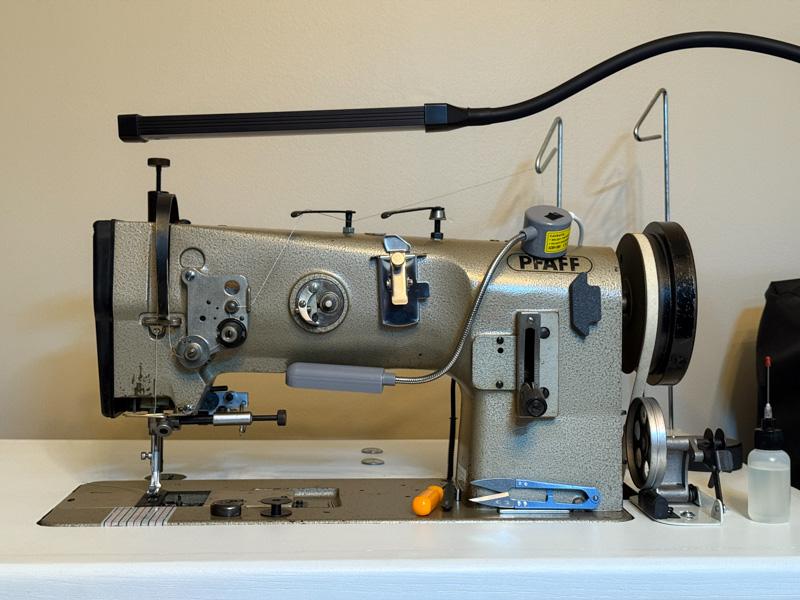

New to the forum. A few basic 3D prints for my Pfaff machines. Basic PLA used.

Collar to fit a 3/4" bore 8" cast iron pulley as a larger hand wheel on a Pfaff 195. Pfaff shaft is 0.501", just a little big for a half inch bore pulley so adapted a larger bore to fit with longer set screws. With a brushed servo motor mounted 1-3/4" pulley, I can get as slow as about 20 stitches per minute.

Also, bought a generic roller guide which doesn't fit all machines directly. Printed an adapter with brass heat inserts for my Pfaff 1245. I was very happy with how easy this was. Still learning best hole sizing for the inserts. Pfaff 1245 uses M5 threads, used the same for the inserts.