-

Posts

6 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by James Roberts

-

-

Hi David,

Sorry this is such a late reply lol.

I use a 1mm braided thread, but it could handle thicker or thinner depending on the needle used.

I don't have any documentation on mine but I do remember using a Landis Champion McKay chainstitch manual as a 'guide' to work through some of the problems. Some of the basic operations are similar.

Did you get yours working yet?

-

Hey all,

I f'd the feed wheel on my (801 copy) skiver and was looking at replacements and it seems there are multiple options. For example;

- emery stone

- rubber (with brass or steel bushings)

- knurled steel

I currently have an emery stone wheel which has worked fine for years, but am interested in what the differences are between the other alternative options?

I am a bootmaker and skive on relatively short lengths but almost always with curves on the pieces. I mostly use this machine to skive ~2.2mm combination tan leather.

Let me know your thoughts on what works best for you!

Cheers,

James

PS: image is a for example purposes only

-

I sold one of these machines about two years ago in Australia for $1200, without the lining trimmer. Not sure if that helps you make up your mind or not.

As far as post machines go, it's a pretty specific use case machine for light weight shoe uppers, with minimal stitch length options, narrow throat etc. If you wanted a post machine for more varied work I'd look for something else. Even certain shoe/boot styles will be difficult to sew with that lining trimmer in the way. I decided to get rid of it before I might have to replace one of the belts driving the feed mechanism.

-

Hi David,

I have a machine that is similar, at least mechanically. Its an old chainstitch one too but isn't the tripod design. From your pictures it looks like you a missing a piece that would slide onto the grooves at the base of the horn that swivels around. It would cover those gears and also be where the thread would go. Mine had this oversized 'bobbin' but I couldn't get it to have a consistent tension so have diyed a different solution to get the thread. I hope these pictures help, shown with the original 'bobbin'.

I think there is another shoemaker in Melbourne, Australia that has one of these tripod machines you could ask for further information, his name is Brendan Dwyer.

Let me know if you have any other questions. The main issues I had with getting it to stitch is adjusting the part that covers the hook on the needle during the correct part of the sewing cycle and also the fine tuning the feed mechanism.

Mine works with standard Champion Mckay needles from Groz-Beckert (part no: HN 83/53.210.62 G 1)

-

Hello,

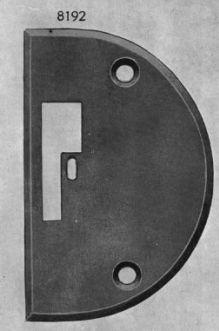

I am refurbishing a Singer model 42-5 Industrial machine and am missing the throat or needle plate, specifically part no 8192 (if you have a different throat plate I would need the appropriate feed dogs, presser feet as well).

Hopefully someone can help me.

The plate should be ~56mm wide, 86mm deep and a bit under 2mm thick, there should also be 60mm between the two screw holes.

Cheers, James (Australia)

Edit: Just realised this should probably be in the wanted forum, if so maybe a moderator could move it.

Shoe repair people advise needed.

in Leatherwork Conversation

Posted

As a shoe repairer and maker, this seems like a good starting place. The Landis machines are the most popular and spare parts are readily available. I'm not familiar with the #36 machine but the Landis 12 K Outsoler is a great machine. A line finisher is of the older style of finishers, totally fine but the modern ones have more options and can take up less space. I run a line finisher but am always looking for a newer one to upgrade to.

For most consumables I am sure there would be a local supplier that sells sanding papers for the finisher as well repair components like heels, soles etc. Maybe https://www.labellesupply.com/

SRI (Shoe Repair International) is a great resource, but it is a Facebook group and membership is limited to people actively in the trade (or adjacent trades).

Also https://thehcc.org/ is a forum of mostly traditional shoemakers with heaps of info.

To round out your repair operation you would probably want a patcher (Singer 29K or Claes/Adler equivalent), maybe a 5-in1 rough rounder, and definitely some ventilation for all the glue. Use Renia adhesives.

To make shoes professionally you would want a post-bed sewing machine, maybe a skiving machine and of course shoe lasts.