Ogoki

Members-

Posts

52 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Ogoki

-

Nice score! I'm jealous. That's the king of outsole stitchers, there. I used one of those in a production facility, but now use a lowly Champion 55 in my home shop. I don't really see the benefit of a servo motor in this case. In my experience (heavy boots), you want flywheel momentum, so low speed stitching really isn't an option, unless you are making light footwear, I suppose... Any old industrial motor would do. The one on my Champion is a 1/3hp/1725rpm. A 1/2hp wouldn't hurt, as the Rapid E flywheels are heavier...

-

Is it perhaps a "flagging" issue? That is to say, as the presser foot climbs onto the seam, is it no longer holding down the material before the seam, allowing it to lift and miss a stitch? In this case a height compensation tool would help.

-

Thanks for the detailed response, Wizcrafts! Much appreciated.

-

What exactly limits bobbin thread weight? I realize that some machines are “meant” for heavier work, but which aspects of the machine explain this in terms of thread capabilities? My twin-needle post-bed and flat-bed have no problems with heavy bobbin threads, but my little Singer 95K43 seems pretty limited. By that I mean that it is difficult to get proper tension with heavier bobbin thread: by the time I get enough needle tension to pull the bobbin thread taught, the lock is appearing on the top of the fabric; also, the needle thread doesn’t look as nice as it does with a thinner bobbin thread; and, it seems to be finicky and require frequent adjusting. I assume this is normal when trying to run a bobbin thread that is too heavy for the machine, but what exactly is the difference in machines that accounts for this? I don't mean this as a question about my 95K, but as a general question about bobbin thread capabilities. Thanks for any musings...

-

Consew and Mitsubishi Twin-Needle machines

Ogoki replied to Ogoki's topic in Leather Sewing Machines

Good eye, Constabulary! Beehive springs seem to be readily available (91-010 183-05), but the check spring (91-010 179-05) does not... -

Consew and Mitsubishi Twin-Needle machines

Ogoki replied to Ogoki's topic in Leather Sewing Machines

I have done so, but I generally consider the manual and its specs to be a starting point. It recommends #14 or #16 needles, but an experienced member on the site has said #18 or #20 needles are fine. My twin-needle post-bed Seiko is a very similar machine, but I notice that its tension disc springs are stiffer. I don’t see why running similar springs wouldn’t help this machine - or at least they would help me in the way of piece of mind! -

Consew and Mitsubishi Twin-Needle machines

Ogoki replied to Ogoki's topic in Leather Sewing Machines

So, I ended up getting the "Mitsubishi" compound feed machine. I am about to order gauge sets, but I could also use a take-up spring and beehive tension-disc springs. I only see take-up springs for the Singer 112 on ebay. Will they work? https://www.ebay.com/itm/5-take-up-check-spring-HEAVY-221175-for-Singer-111w-112W-211u-Consew-225-226/261685705754?hash=item3cedaefc1a:m:mjecIiumG8-X_AaRhoRA0QA Is there a readily available tension disc spring for a similar machine that would be stiffer (even just some common Singer industrial model, e.g. 31K)? The ones on this Mitsubishi are squished pretty flat with the #6 cotton thread that I am using... Thanks again. -

Consew and Mitsubishi Twin-Needle machines

Ogoki replied to Ogoki's topic in Leather Sewing Machines

The lack of reverse isn't a big deal... Is it possible to fit a non-walking foot to the walking-foot machine, out of curiosity? -

Consew and Mitsubishi Twin-Needle machines

Ogoki replied to Ogoki's topic in Leather Sewing Machines

OK, so gauge sets are available for either. Here is shot of the Seiko presser foot. The foot looks like the walking foot gauge sets I see on ebay. -

Hello all, I am looking at picking up a twin-needle flat bed, a see a couple for sale locally. One is a Consew STW-8M. The casting looks very much like my Seiko twin-needle post-bed, and the model number seems like a Seiko number, so I am thinking maybe it was made by Seiko. Is this a walking foot machine? And are gauge sets available for it? The other is a Mitsubishi DN-260. I gather from another post on here that it is a compound-feed machine. I am also curious about gauge sets for this one. Thanks for any info.

-

Union Special 51900 Alternate Presser Foot?

Ogoki replied to Ogoki's topic in Leather Sewing Machines

Thanks again! I'll have a look through that pdf and see what I can find out about the looper. -

Union Special 51900 Alternate Presser Foot?

Ogoki replied to Ogoki's topic in Leather Sewing Machines

From what I can see on the Union Special site, there is only a parts manual for this series. My experience with chainstitchers is limited to my Champion 77 and an old Puritan triple stitcher, both of which are single thread machines (if I recall the Puritan correctly), and different from these two-thread machines. In any case, I am confident that with a manual and/or a bit of guidance, I can wrap my mind around this. The "flagging" issue seems to be virtually non-existant when stitching a few layers of 15oz. denim (at the risk of getting the boot I must admit that this isn't being used for leatherwork), so I feel that I could ignore that variable with the right troubleshooting material, i.e. three flat layers of 15oz. denim. The flagging occurs with thin materials, and it also skips when going over the seams, where I might have more like 12 layers of denim (I do use a height compensation tool to pin down the fabric by the needle, and walk the machine over the seams very slowly). And, of course, when reducing the stitch length the machine becomes basically useless, which is the problem I would really like to solve. Is there a proper service manual for any similar machine that might help me? I also recently picked up a baby lock serger, which is a serger and a chainstitcher. It doesn't loop properly either, so I think it is time to learn about chainstitching machines.... -

Union Special 51900 Alternate Presser Foot?

Ogoki replied to Ogoki's topic in Leather Sewing Machines

I set the machine to a stitch length that looks much nicer, but it started skipping stitches like crazy. So, I backed it off and seem to have found a sweet spot where it skips very rarely, but is still too long for my liking. Any ideas as to why it wouldn't loop properly with a shorter stitch length? Does tension generally need to be adjusted with stitch length on one of these? Or does that sound like it needs a needle/looper/timing adjustment? If so, is there a proper manual for these things with an "Instructions for machinists and adjusters" section? I am happy to improvise with my own machines at home, but not so much at this job... -

Union Special 51900 Alternate Presser Foot?

Ogoki replied to Ogoki's topic in Leather Sewing Machines

Much appreciated!!! -

Union Special 51900 Alternate Presser Foot?

Ogoki replied to Ogoki's topic in Leather Sewing Machines

OK, so I guess my best bet is to find the original 3-needle foot. I just found the Union Special parts manuals and it seems that the part numbers are 35820 P-8 and P-9, if that makes sense. Those stitch-length instructions would be great, if you have them. The stitch length on this particular machine is rather long and it looks kind of ugly... The Union Special site just seems to have parts manuals, which do have basic oiling and threading instructions, but that seems to be it. Thanks again. -

Union Special 51900 Alternate Presser Foot?

Ogoki replied to Ogoki's topic in Leather Sewing Machines

Hi Eric, Thanks for the response! I will check the number on the throat plate next time I'm there. Right now I am using a size 20 needle, if that helps you any. Are those part numbers meant for this machine in its stock, 3-needle operation? Or are they single-needle variants? Also, is it really not possible to adjust the stitch length on this machine? I have been told it isn't, and I don't see any obvious way to do so... Thanks again. Kevin -

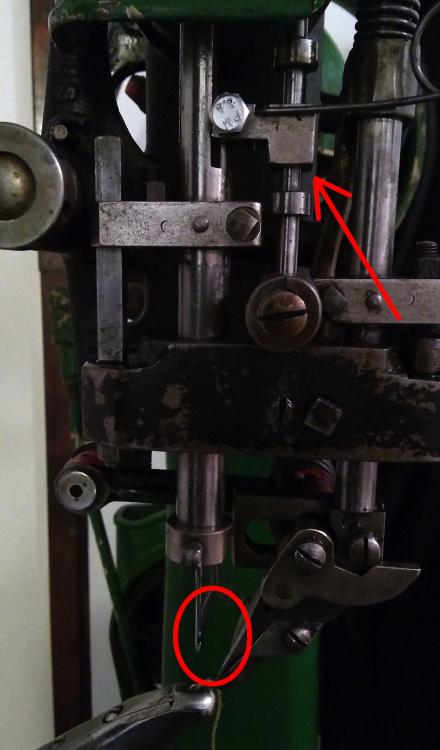

Hello all, I have been doing some work lately on a Union Special 51900BH. This would have been a triple needle chainstitch machine, but it is operating on one needle only for its current purpose. I have been getting a lot of skipped stitches on the lighter materials. I am pretty sure this is due to the gaping hole in the presser foot around the needle, which allows the sleazier materials to lift with the needle. Does anybody know which presser feet will interchange with this machine? Below is a picture of the one that is currently on there. I see one on ebay (#52820) that looks like it might work, but I would rather not gamble, if somebody knows the answer... http://www.ebay.com/itm/1-new-5280-16-presser-foot-for-UNION-SPECIAL-52800-52900-sewing-machines-/291692870613?epid=1971259328&hash=item43ea3ffbd5:g:TcIAAOSwDuJWzfDX Going by the parts book, it also looks like a #6520 might work, but again, I am guessing. Are there any Union Special experts out there? Thanks for any help.

-

Will do! Thank you.

-

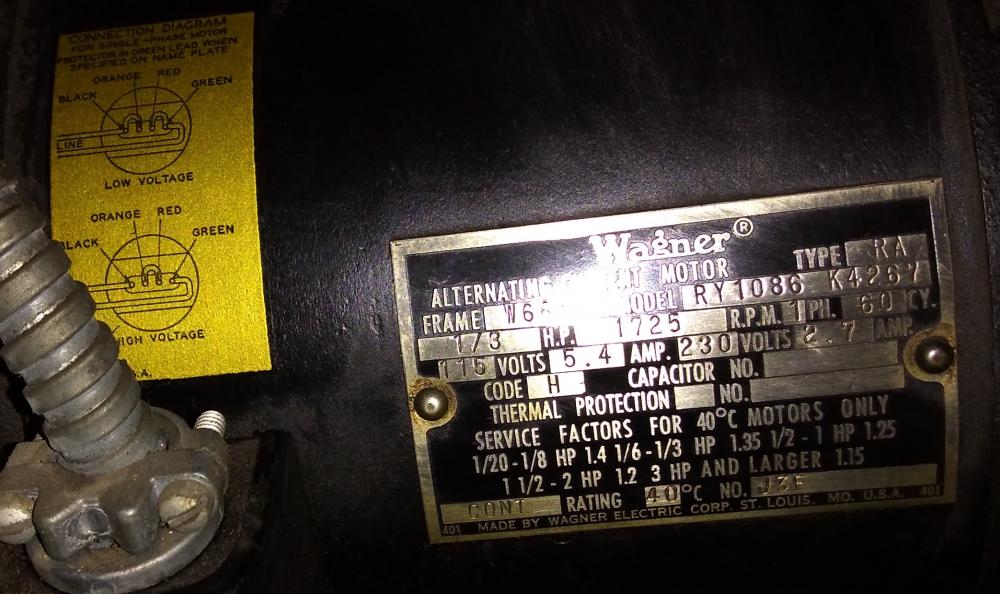

Hello all, I recently acquired a Champion 55 curved-needle outsole stitcher and I have a few questions... First, the belt from the clutch to the head is a round leather belt, twisted once for proper rotation. The machine has two pulleys at the clutch, and the low speed one is currently in use. I would like to run the high speed pulley, which requires a longer belt. I thought a V belt might be nicer than the slippy leather belt, but that would mean reversing the rotation of the motor, as I obviously can't twist a V belt. Are there any motor experts out there who can make an educated guess as to which leads to reverse (if possible) in order to reverse the rotation? Please see the attached picture. Second, I am having a problem with the machine not pulling the lock into the sole, as if there is not enough bottom tension. From what I can tell, the issue is that I can't quite get enough tension before the thread starts to slip on itself on the tension wheel, rather than turn the tension wheel. I have the thread wrapped around the wheel three times, as twice certainly wasn't enough. I am using CB554 bonded nylon thread, without stitching wax or thread lubricant. I have no desire to run hot wax, and have a good deal of experience running a Rapid E similarly dry with the same thread and no problems. (Yes, I am well aware that this machine is no Rapid E!!!) Would either thread lubricant or stitching wax help me get more thread-on-thread tension on the tension wheel, or at least help the machine pull the lock into the sole? I have stitched a bunch of pairs successfully, but every once in a while it will just start to crap out and not pull the lock into place. Any thoughts? (I have adjusted the machine to measure out as little thread as possible, which should mean a deeper lock, so that isn't the problem.) Any thoughts on either issue would be appreciated!

-

It turns out that cast off screw was very close to the problem. I managed to remove the cast off assembly, and the block was bulged out, presumably from years of over-tightening that screw against the cast off. I sanded the bulge flat and cleaned and oiled and reassembled and managed to stitch a couple of boots. Now it is sticking again but the block is fine and the problem seems to be a bent cast off. For the time being I will try to straighten it, but is there a supplier for parts for this thing? I see needles around, but what about cast offs? This one has probably seen more than its share of use. And what kind of thickness can these things handle? I can't imagine that I am pushing it in that regard, but who knows... Thanks again.

-

Thanks for the responses, guys. I do have an old hard copy of the manual, as well as that pdf. The cast-off screw is a 6mm bolt, and the threads in the block aren't pretty, but I will need a bottoming tap to clean them up properly. In any case, it does its job of holding the cast-off in place as is. The spring is probably weak, but that little spring couldn't push the block back into place even if it were in good shape. I would like to remove the block and its shaft, but the manual doesn't exactly have step-by-step disassembly instructions... Unfortunately my workshop is in my apartment and the upstairs neighbours wouldn't appreciate kerosene. Is a wax remover less smelly? I have tried heating the shaft, hoping to wick away any wax that might remain, to no avail. Thanks again.

-

Hi all, I recently picked up an old McKay Champion 77 stitcher, and I have a few initial questions. First, thread. The fellow from whom I purchased the unit mentioned that it should take a left twist thread. Can anybody confirm this? Also, what should be used in the wax pot? The local supplier has thread lubricator and stitching wax. Or, is there a thread that can be used without liquid? I used to operate a Rapid E outsole stitcher, and we used heavy bonded nylon thread without any wax or lube. Something like this would be preferable (just in that I assume it is less messy). Second, I have a problem with the cast-off in that it sticks in the upward position and the needle consequently drops the thread loop. The little cast-off block is sticky on its shaft, and I need to push it back down into position with a screwdriver. I assume it should slide around freely on that shaft when the return spring is removed. Any thoughts on this? Thanks for any responses.

-

I spoke with a woman the other day who used to work in a glove manufacturing plant and, surprisingly, she said they used flat-bed walking-foot machines. I'm still leaning toward a cylinder machine, but I'm wondering if it's possible to put a flat-bed attachment (I don't even know if such a thing exists) on a cylinder or post-bed machine? Or has anybody fabricated such a piece? Yeah, hopefully the Rangers can even things out tomorrow...

-

Thanks for the response. That's kind of what I was hoping to hear. Do you have a favourite for the Cup?

-

Hello all, I am looking to get into making gloves, and I am wondering if anybody can offer any recommendations for machines. I just started sewing recently, and I'm using a commercial Kenmore machine, which was given to me. It seems to sew my material fine, but the flat bed is not great and the presser feet I have are just too big for the job. I have lifted the presser foot and used my fingers and the hand crank in the tricky corners, but I can't get good tension that way. It seems that machines with a really small post bed - "finger bed"? - are used, and I have come across the Singer 91K5, 46K, as well as Kansai and Porkert versions. The Singer 91K5 seems to be easy enough to find (although not exactly cheap), but my main concern is regarding the stitch type, as it is a chain stitch machine. Should I worry about chain-stitching unravelling if the stitches are nicked? The gloves will be for work and riding. Also, would a cylinder or post-bed machine be appropriate? I would rather go this route, as I would eventually like to sew boot uppers, and I think that a machine like this would be much more useful overall. Thanks for any responses!