-

Content Count

76 -

Joined

-

Last visited

Posts posted by Mizzy

-

-

Hahaha ... I have about 30 Dikman, and yes Rocky, one would hope.

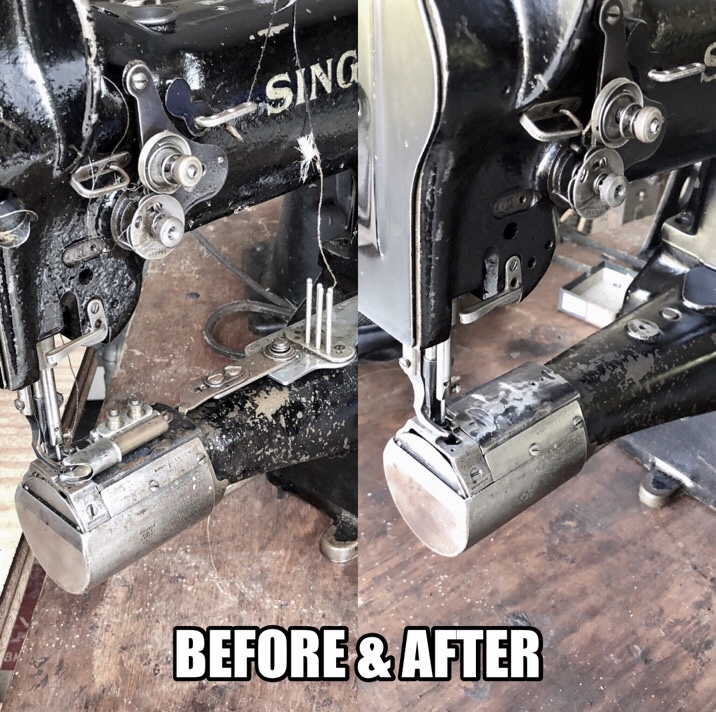

This old girl is my favourite, I’ve been using her almost exclusively for years now. She does a beautiful zigzag and straight stitch, and she almost punches through tin. Hopefully still does. I’ve just put a Doso DS 28 servo on her and once I figure out how to line the pulleys up I’ll find out.

-

-

-

Yes, and therefore the finger part wasn’t contacting the plunger part.

-

-

Hi Dikman, great suggestion, thank you. I’ve considered that but wasn’t sure if a longer one might damage some delicate internal mechanism. I have no diagrams on the plunger setup whatsoever. I’m wary too of altering any part without knowledge of its workings, as I have read some great advice somewhere on here that if you don’t know what a screw does, and by extension, any part really, then don’t touch it. I think it was constabulary or wiz.

The other day my husband had the machine on it’s back (with brackets removed from the back thereby allowing full access to the button) and the damn thing fell out. It wasn’t a little button after all but a rod! I was surprised to discover it was, as you say, just like a nail.

Over the past few days I realised that the tension set screw just didn’t grasp the tension assembly tight enough, and no screw in the house would substitute. Not even off other machines (I’ve got a graveyard here). So my builder son ground the setscrew to a point and the result is an unmovable tension stud now. I think that was half the problem.

So at this point I’m waiting the 4-6 weeks for a new tension assembly to arrive from China - and hopefully it’s the correct part this time.

-

Hi Constabulary, yes I think I’ve fixed it thanks to you and Rocky. I’ve purchased two complete tension assembly units over the years (on EBay) using the part number for a complete piece, but the problem remained. I’ve used the information you both provided to determine that I had the wrong part! The little finger on top of each tension unit just isn’t long enough to push back into it’s popped out position the tension release plunger at the back. Hopefully third time lucky; I’ve just ordered another from a different eBay company. The trouble I have here in a somewhat isolated rural area is I must rely on postage - I can never view before I buy. Oftentimes the postage is expensive too, hence the reason I choose eBay. Before I searched on eBay I tried to buy a tension unit from the Uk for $10 but postage was $90! But eBay too can be expensive. Recently I purchased a serger manual - photocopied and sent via email - and was charged $75 for the non-existent postage. I successfully got my money back on that one.

I truly appreciate the advice I receive here, thank you both so much.

-

Thank you Dikman

-

Hello, sorry for coming in late here.

I’m about to put a servo motor underneath my 153w103, but I’m hesitating. Will a Doso DS 28 (3/4 hp) servo motor suffice, or do I need more grunt?

Any advice will be greatly appreciated.

-

Thank you so much!

-

-

I have a Singer 107w1 with a tension release plunger that doesn’t work, but I can’t find any information about it anywhere. There’s nothing in the manual, and only a picture and part number in the parts book. I can’t find any diagrams, utube clips, or detailed instructions on how to pull it apart. Indeed, the plunger (looks like a thick steel nail or rod) goes into what seems to be just a hole drilled into solid cast iron. I’ve taken the tension assembly off and the plunger hole doesn’t continue through to the tension assembly side. So how does it work? I’m stumped!

The button goes in at the back when the lifter bar lifts and presses against it, but only comes out again if I lay the machine over on its back. However, even when the button is depressed, pushed into the hole) it doesn’t release the tension discs as it is apparently supposed to.

Can anyone help me please?

-

Thank you Sheltathelore!

-

On 21/04/2018 at 11:56 PM, Darren Brosowski said:I am in NSW and happy to help as I love old machines.

Call me on 0415 353 748Hi Darren, did you get my private message?

-

Thanks Dikman, I just looked at it on utube and seems useful. But I’d rather it removable, not permanent.

Sorry for asking a silly question, but what would happen if I didn’t replace the feet and feed dog assembly? Not sew straight perhaps?

-

2 hours ago, dikman said:Mizzy, hubby's garage must look like Aladdin's Cave!

Hahaha it sure does ... to me anyway.

-

-

Thanks, yes I’m very happy with my find but sad for the man who once loved these machines - I’d say he was into collecting antique Singers. I certainly don’t need them all but his dear wife was sending them to the dump the next day; she had no idea about their condition, function, or value. Me either, but I couldn’t see them scrapped.

All bar 2 are Singers, most are still black albeit dulled and dirty beasts but with intact decals, and many have weird looking attachments stuck all over them. The manuals are original and like new.

I couldn’t find a replacement bobbin cover for the 153w103 so I pulled the binding (or whatever) attachment thingy off the existing cover. It had been welded onto the original bobbin cover but a hacksaw did the trick. I’ve cleaned the head, ordered a new timing belt as it was broken, and might stick a new servo underneath. Utube makes that job look doable. However, being a little female means I’m limited by a lack of strength- it’s heavy and some of the screws feel like they’re glued in place.

Can anyone please tell me if it’s possible to replace wheels for presser feet? Would I need to replace the feed dog (and plate) too?

-

Amazing, right? I went looking to buy a walking foot Singer 153w103, expecting to pay $1,000 to $1,500, but ended up getting the whole shed full of machines for $500.

So there are post bed machines, bar trackers, button hole machines, old Singer heads galore, an Irish embroidery machine, ... so many. I’ve started up the biggest, a mec Val cs82, which seems to run well, but don’t actually know anything about it or even want it. Can anyone tell me what it’s worth? My husband is pretty keen to get his garage back.

One of the machines is a Singer 236w100 and I’m thinking of repainting it as a project. Another machine, a Singer 331k6, has a roller foot but I was wondering if I can change that to a normal presser foot?

Well I’m excited! What a find!

-

I'm back!

Constabulary I actually purchased the machine about 18 months ago and hadn't even turned it on until a few weeks ago as my Singer 107w1 and Siruba DBA525 twin needle handle most jobs. This particular walking foot Singer that I'm having problems with has a servo motor with automatic stitching and thread trimming and is rather intimidating to operate without a manual so I didn't even try to use it until recently, however, I did see it work before I bought it yet I don't recall the feet not lifting in the sale demo. It was transported in the back of a ute over 700kms of rough Australian roads to get here so maybe something has come loose as you suggest. I'll work out how to remove the cover and video the moving parts next. Thank you for your reply.

Tejas thank you for your kind offer. How do I contact you ?

-

Constabulary, I moved it down to the bottom notch but nothing changed. Vielen herzlichen Dank!

Cowboy, I can push the button down and it clicked into place but the handwheel doesn't move towards me, and I've been pulling it as hard as I could. Thanks so much for your help!

Pcox, because the button didn't work I stuck a screwdriver into the slotted disc just like you said to do and braced it against the body (I couldn't hold it) and was able to rotate the round hunk of metal that the ring encircles but this didn't affect the presser height. But I really appreciate your help!

I'm so frustrated! It's like the inner foot is stuck onto the feeddog and synchronised to move with it, going backward and forwards in exact time with each thrust of the feeddog, but never actually lifting off it. I'd say that's why my fabric is getting chewed up.

I'm heading off for a holiday this afternoon and will get back into it the moment I get back in 2 weeks time. Thanks for your help guys

-

Hey!

Hopefully you might be able to guide me in adjusting the height of my Singer 211 presser feed, particularly the middle part. I don't have a manual so I can't determine the precise model. I believe it's a 211A, however, my understanding is that there are further categories of this 211A class differentiated by feed mechanisms. I'm not familiar with technical terms regarding the mechanics but in novice terms my walking feet are not walking much! The middle presser part doesn't appear to lift much, if at all. Furthermore, material is getting caught at the back (but not always), bunching up, and left with track marks and holes no matter the thickness - leather or lightweight cotton. I've recently learned that I need to adjust the presser feet ... but how?

Here is a short clip of the feet in action.

Thanks!

-

-

Hello from Australia. This is my first post as I only found this informative site a few days ago. I hope someone can help me in my search for answers regarding my hungry Singer 211.

Firstly, if the middle presser foot doesn't lift then would this be a double (as opposed to triple) feed walking foot machine (I have no manual). If correct, then would this machine be a 211A157?

Secondly, why would the feet leave deep track marks, cuts, and even holes in thick leather or thin fabric? I haven't used thread yet, just trying out the mechanics.

The material tends to bunch up at the back, as if the feet are holding on to it still. Often it runs smoothly then for no apparent reason it occasionally just sits there and pounds away on the same spot until it rips the fabric apart.

I eagerly await your input.

Mizzy

Singer 107w1 tension release rod

in Leather Sewing Machines

Posted · Report reply